Preparation method of pseudomonas aeruginosa-resistant nano-composite paper

A Pseudomonas aeruginosa, nanocomposite technology, applied in chemical instruments and methods, paper, papermaking, etc., can solve the problems of limited antibacterial species, influence of tension resistance, flexibility performance, influence of tension resistance and flexibility, etc. Avoid adverse effects, have significant antibacterial effect, and improve the effect of antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

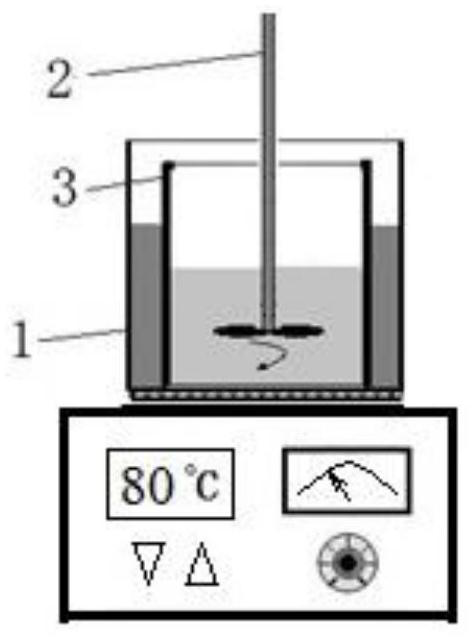

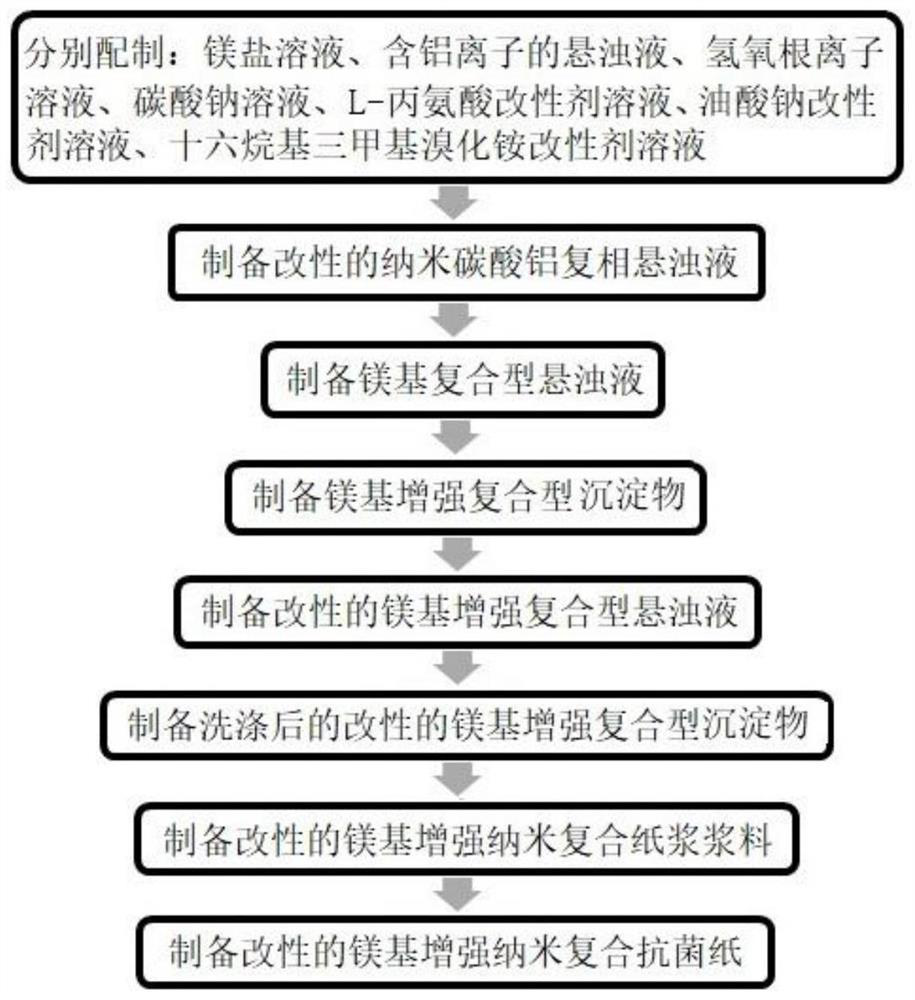

Method used

Image

Examples

Embodiment 1

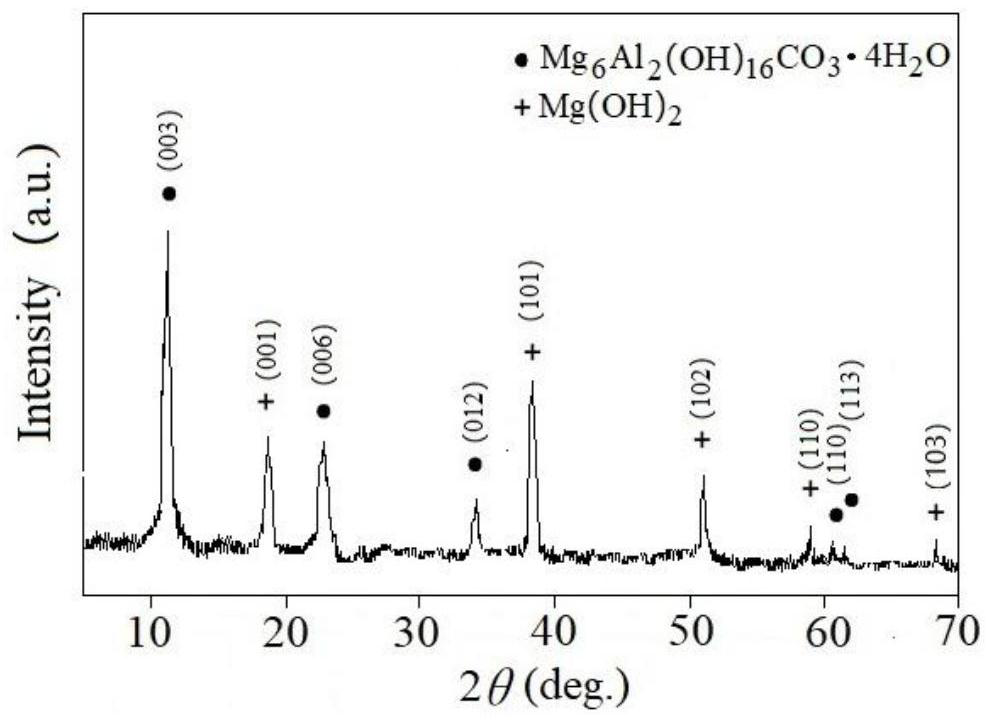

[0064] Example 1, preparing a composite antibacterial paper containing 64.3% magnesium aluminum hydrotalcite and 35.7% magnesium hydroxide nanocrystals in the modified magnesium-based reinforced composite precipitate after washing.

[0065] Step 1, prepare a magnesium salt solution with magnesium chloride and magnesium nitrate at a molar ratio of 1:1.

[0066] 1.1) 27.611 grams of MgCl 2 and 43.01 g of Mg(NO 3 ) 2 Dissolve in 1000ml deionized water and mix;

[0067] 1.2) Filter to remove impurities in the magnesium salt solution, and prepare a magnesium salt solution with a concentration of 0.58mol / L:

[0068] 1.2.1) Put the funnel on the instrument support, and put the clean beaker under the funnel;

[0069] 1.2.2) Fold the filter paper onto the funnel;

[0070] 1.2.3) Pour the magnesium salt solution onto the filter paper at a rate of 50 ml / min to obtain a magnesium salt solution.

[0071] Step 2, prepare hydroxide ion solution.

[0072] Dissolve 51 g of NaOH into 150...

Embodiment 2

[0102] Example 2, preparing a composite antibacterial paper containing 71.5% magnesium aluminum hydrotalcite and 28.5% magnesium hydroxide nanocrystals in the modified magnesium-based reinforced composite precipitate after washing.

[0103] Step 1, using magnesium chloride and magnesium nitrate with a molar ratio of 1:1 to prepare a magnesium salt solution.

[0104] 1a) 37.132 grams of MgCl 2 and 57.841 g of Mg(NO 3 ) 2 Dissolve in 1000ml deionized water and mix;

[0105] 1b) filter to remove impurities in the magnesium salt solution, and prepare a magnesium salt solution with a concentration of 0.78mol / L:

[0106] The specific implementation of this step is the same as step 1.2) of Example 1.

[0107] Step 2, dissolve 79.2 grams of NaOH into 1500 ml of deionized water and mix to prepare a hydroxide ion solution with a concentration of 1.32 mol / L.

[0108] Step three, the Na of 22.26g 2 CO 3 Dissolve in 500mL of deionized water to prepare a sodium carbonate solution wit...

Embodiment 3

[0135] Example 3, preparation of composite antibacterial paper containing 73.8% magnesium aluminum hydrotalcite and 26.2% magnesium hydroxide nanocrystals in the modified magnesium-based reinforced composite precipitate after washing.

[0136] Step A, prepare a magnesium salt solution with magnesium chloride and magnesium nitrate with a molar ratio of 1:1: dissolve 60 g of magnesium chloride and 93.24 g of magnesium nitrate in 1000 mL of deionized water and mix, filter to remove impurities in the magnesium salt solution, and prepare Concentration is the magnesium salt solution of 1.26mol / L, wherein filtration removes the impurity in the magnesium salt solution, and its realization process is identical with step 1.2) among the embodiment 1.

[0137] Step B, preparing a hydroxide ion solution: dissolving 87g of NaOH into 1500mL of deionized water and mixing to prepare a hydroxide ion solution with a concentration of 1.45mol / L.

[0138] Step C, prepare sodium carbonate solution: ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com