Zirconia ceramic as well as preparation method and application thereof

A zirconia ceramic and zirconia technology are applied in the field of zirconia ceramics and their preparation to achieve the effects of low dielectric constant and density, good toughness and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

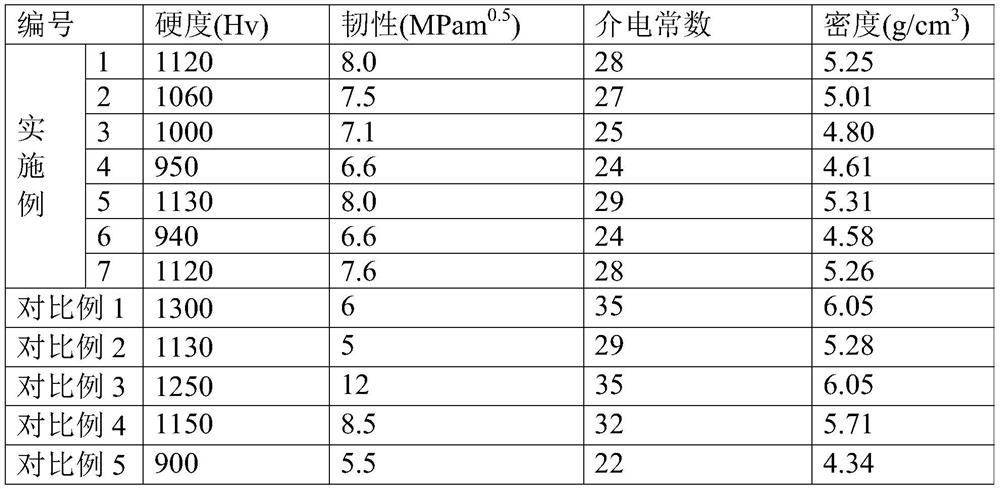

Examples

preparation example Construction

[0023] The second aspect of the present invention provides a method of preparing zirconia ceramics comprising: (1) wet oligium oxide zirconia, niobium oxide and cordierite, and the dispersant and water, then The binder is formed, and the slurry is formed; (2) drying the slurry to obtain a composite zirconia powder; (3) performs the composite zirconia powder to be molded, and then sintered in air to obtain ceramics.

[0024] In the present invention, the oxide zirconia-containing zirconia, and the powder of niobium oxide and cordierite can be provided separately or in combination with high purity powder. For example, yttrium oxide, zirconia can be used to stabilize zirconia powder containing 1.5-4 mol% cerium oxide (0.3-0.6 μm in the particle size, 7-13m specific surface area) 2 / g), wherein the content of yttrium oxide is based on zirconia. Niobium oxide can be used in a niobium bismuth (particle diameter medium value of 8-10 μm) powder. Cordierite uses a powder having a particle...

Embodiment 1

[0047] Pentoxide (NB) 2 O 5 25 g, zirconia powder containing 3.2 mol% cerium oxide stabilized zirconia powder 855g, cordierite 120g, binder (polyvinyl alcohol) 77.78 g, dispersant (triethanolamine) 1 g.

[0048] Zirconia, cordierite, niobium bismuth, water, and dispersant are sandwiched in the sand mill, and the binder is added to form a slurry for spray, and the solid content is 25% by weight;

[0049] The slurry is fed into the spray column for spray drying (the air intake temperature is 250 ° C, the air is 110 ° C, the centrifugal rotation speed is 15 revolving per second) forms a spherical powder having a strong fluidity, and then drying (Tonname 200 tons of pressurized press using 8MPa oil pressure pressure);

[0050] The molded powder was sintered at 1320 ° C in the air.

[0051] The sintered product was polished and the laser was cut, that is, the final sample was made, and the size was the shape and size of the back cover, 150 * 75 * 0.6mm.

[0052] High-energy XRF detecti...

Embodiment 2

[0055] Pentoxide (NB) 2 O 5 25 g, containing 3.2 mol% cerium oxide stabilized zirconia powder 815g, cordierite 160g, binder (polyvinyl alcohol) 77.78 g, dispersing agent (triethanolamine) 1 g.

[0056] Zirconia, cordierite, niobium bismuth, water, and dispersant are sandwiched in the sand mill, and the binder is added to form a slurry for spray, and the solid content is 25% by weight;

[0057] The slurry is fed into the spray column for spray drying (the air intake temperature is 250 ° C, the air is 110 ° C, the centrifugal rotation speed is 15 revolving per second) forms a spherical powder having a strong fluidity, and then drying (Tonname 200 tons of pressurized press using 8MPa oil pressure pressure);

[0058] The molded powder was sintered at 1320 ° C in the air.

[0059] The sintered product was polished and the laser was cut, that is, the final sample was made, and the size was the shape and size of the back cover, 150 * 75 * 0.6mm.

[0060] A high-energy XRF detection was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com