Three-dimensional high-thermal-conductivity white light LED and production method thereof

A high thermal conductivity, LED chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems that threaten the luminous efficiency and long-term reliability of white LEDs, increase the temperature of fluorescent materials, and reduce the light conversion efficiency of fluorescent materials. Improve long-term work reliability, high luminous efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

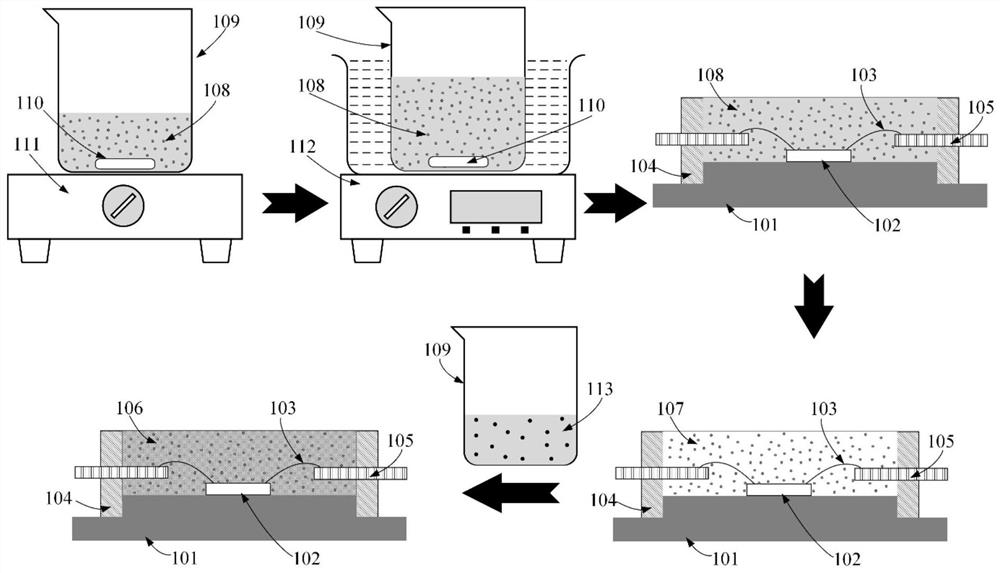

[0043] like figure 2 As shown, the embodiment of the present invention also provides a preparation method of the three-dimensional high thermal conductivity white light LED, which includes the following steps:

[0044] S1 First, according to the overall structure of the three-dimensional high thermal conductivity white light LED, assemble the substrate 101, the reflective cavity 104, the LED chip 102 and the lead parts according to the relative positions of each other;

[0045] S2 Then mix deionized water, alkyl glycosides, non-light-absorbing thermally conductive fillers, fluorescent powder, curdlan gum and gellan gum according to a preset ratio, stir and heat to obtain a volume-expanded mixed solution;

[0046] S3 Then inject the volume-expanded mixed solution into the assembled reflective cavity 104, and cool to obtain a three-dimensional high thermal conductivity skeleton. The main body of the skeleton is a non-light-absorbing heat-conducting filler and phosphor particles...

Embodiment 1

[0058] see figure 2 , the present embodiment adopts hexagonal boron nitride, the average particle size is 45 μm; the phosphor is YAG, the average particle size is 13 μm, and the emission wavelength is 538 nm; the packaging glue is silica gel; the average particle size of quantum dot nanoparticles is 13 nm, and the emission wavelength 626nm, the chemical composition is cadmium selenide, the mass concentration of the quantum dot nanoparticle solution is 10mg / ml, the LED chip is a formal structure, and the substrate is sapphire. Specifically include the following steps:

[0059]S1 Take 100ml of deionized water, add 1ml of alkyl glycoside (APG), 3g of boron nitride, 2.5g of fluorescent powder, 1g of curdlan gum, and 1g of gellan gum to obtain a mixed solution 108, and put the mixed solution 108 into a magnetic stirrer On 111, set the rotation speed at 900 revolutions per minute, and stir for 15 minutes. The curdlan gum is fully dissolved by high-speed stirring, and a large numbe...

Embodiment 2

[0065] In this embodiment, hexagonal boron nitride is used, with an average particle size of 15 μm; the phosphor is YAG, with an average particle size of 18 μm, and a light emission wavelength of 558 nm; the packaging glue is silica gel; the average particle size of quantum dot nanoparticles is 15 nm, and the light emission wavelength is 635nm, the chemical composition is perovskite, the mass concentration of the quantum dot nanoparticle solution is 15mg / ml, the LED chip is a horizontal electrode chip, and the substrate is silicon. Specifically include the following steps:

[0066] S1 Take 100ml of deionized water, add 0.5ml of alkyl glycoside (APG), 2.5g of boron nitride, 1.5g of fluorescent powder, 0.5g of curdlan gum, and 0.5g of gellan gum to obtain a mixed solution 108, and put the mixed solution 108 into Put it on the magnetic stirrer 111, set the rotation speed at 1200 rpm, and stir for 10 minutes, fully dissolve the curdlan by high-speed stirring, and introduce a large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com