Nanofiber-based microsphere composite membrane and preparation method thereof

A nanofiber and composite membrane technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of limited development, poor mechanical properties of microspheres, agglomeration, etc., achieve high economic and time benefit advantages, and easy to promote industrialization. , the effect of excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The purpose of the present invention is to provide a method for preparing a nanofiber-based microsphere composite membrane, which rapidly prepares a composite membrane in which microspheres and nanofibers coexist by using electrospinning technology. The solution components for electrospinning are one or more of polymers such as polycaprolactone, polylactic acid, polyvinyl alcohol, polystyrene, silk fibroin, wool protein, chitosan and collagen. Specific steps are as follows:

[0031] (1) Preparation of electrospinning solution

[0032] Slowly pour 1 to 10 g of polycaprolactone (Polycaprolactone, PCL) with an average molecular weight of 30,000 to 80,000 into 50 to 200 mL of chloroform (CHCl 3 ) at 20-30°C at a speed of 800-2000 rpm for 3-6 hours until completely dissolved. Then use an ultrasonic disperser, with an amplitude of 10-40%, ultrasonically disperse for 3-30 minutes to disperse evenly, and then place it in an oven at a temperature of 35-55°C to defoam for 1-30 ...

Embodiment 1

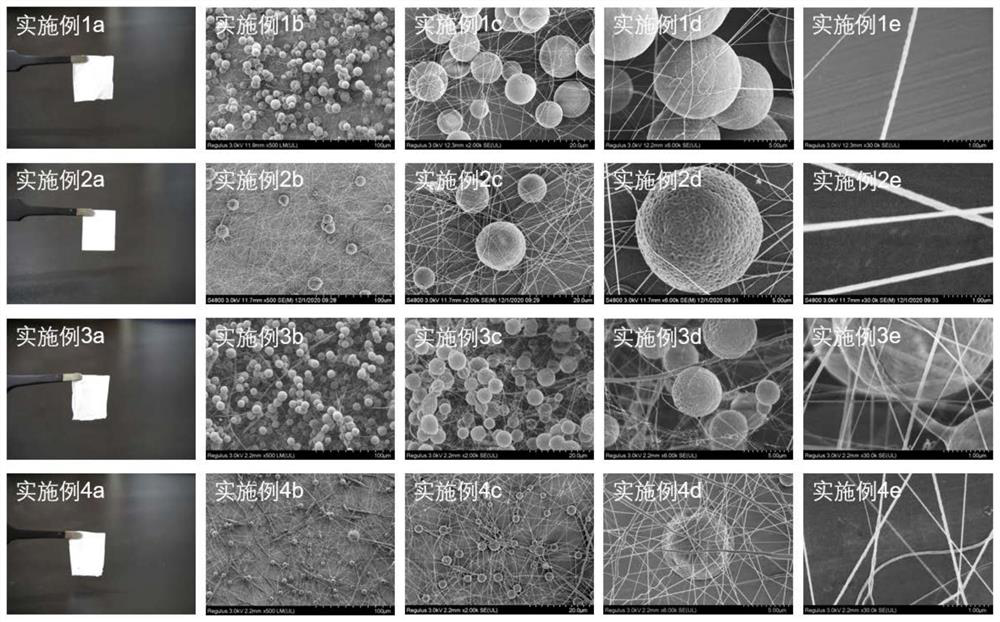

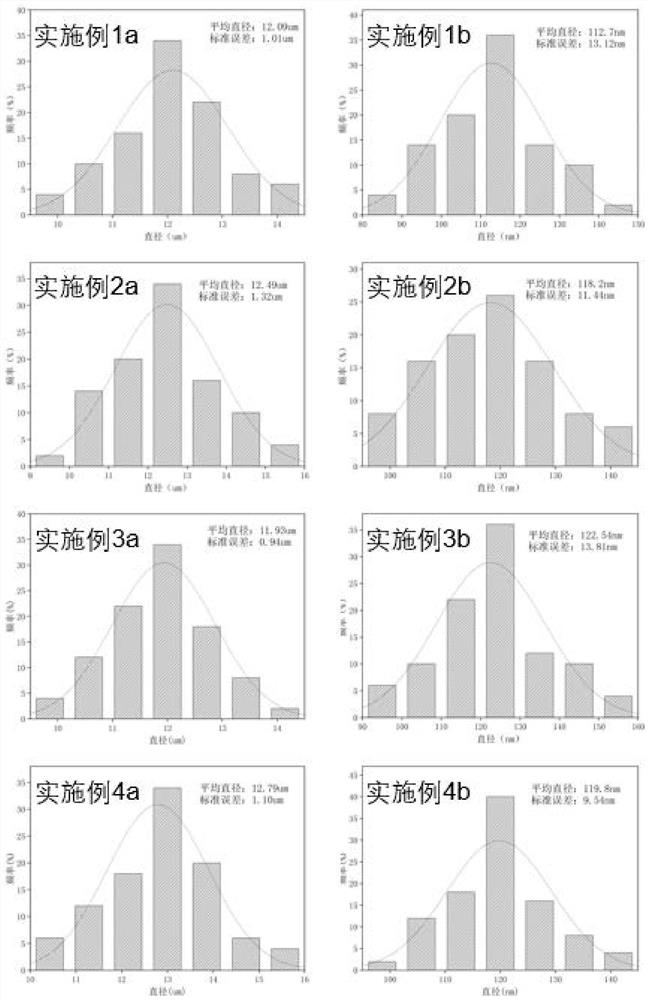

[0040] This implementation case shows a "one-step method" to efficiently prepare a composite film with uniform distribution of nanofibers and microspheres through high-voltage electrospinning technology. The steps are as follows:

[0041] (1) Preparation of electrospinning solution

[0042]Slowly pour 1-10 g of polycaprolactone (Polycaprolactone, PCL) with an average molecular weight of 5000-50000 into 50-200 mL of chloroform (CHCl 3 ) at 20-30°C at a speed of 800-2000 rpm for 3-6 hours until completely dissolved. Then use an ultrasonic disperser, with an amplitude of 10-40%, ultrasonically disperse for 3-30 minutes to disperse evenly, and then place it in an oven at a temperature of 35-55°C to defoam for 1-30 minutes under dark and sealed conditions. After 12 hours, a PCL solution with a mass fraction of 5-12% was obtained for use.

[0043] (2) Electrospinning

[0044] Prepare the nanofiber-based microsphere composite film by high-voltage electrospinning technology; put th...

Embodiment 2

[0048] This implementation case shows a "one-step method" to efficiently prepare a composite film with uniform distribution of nanofibers and microspheres through high-voltage electrospinning technology. The steps are as follows:

[0049] (1) Preparation of electrospinning solution

[0050] Slowly pour 1-10 g of polycaprolactone (Polycaprolactone, PCL) with an average molecular weight of 5000-50000 into 50-200 mL of chloroform (CHCl 3 ) at 20-30°C at a speed of 800-2000 rpm for 3-6 hours until completely dissolved. Then use an ultrasonic disperser, with an amplitude of 10-40%, ultrasonically disperse for 3-30 minutes to disperse evenly, and then place it in an oven at a temperature of 35-55°C to defoam for 1-30 minutes under dark and sealed conditions. After 12 hours, a PCL solution with a mass fraction of 12-20% was obtained for use.

[0051] (2) Electrospinning

[0052] Prepare the nanofiber-based microsphere composite film by high-voltage electrospinning technology; put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com