Large moving range macro-micro dual drive locating platform

A positioning platform and large movement technology, applied to the parts of the instrument, the instrument, the shell, etc., can solve the problems of low movement speed, difficulty in high-speed movement, small size, generally only tens of microns to hundreds of microns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

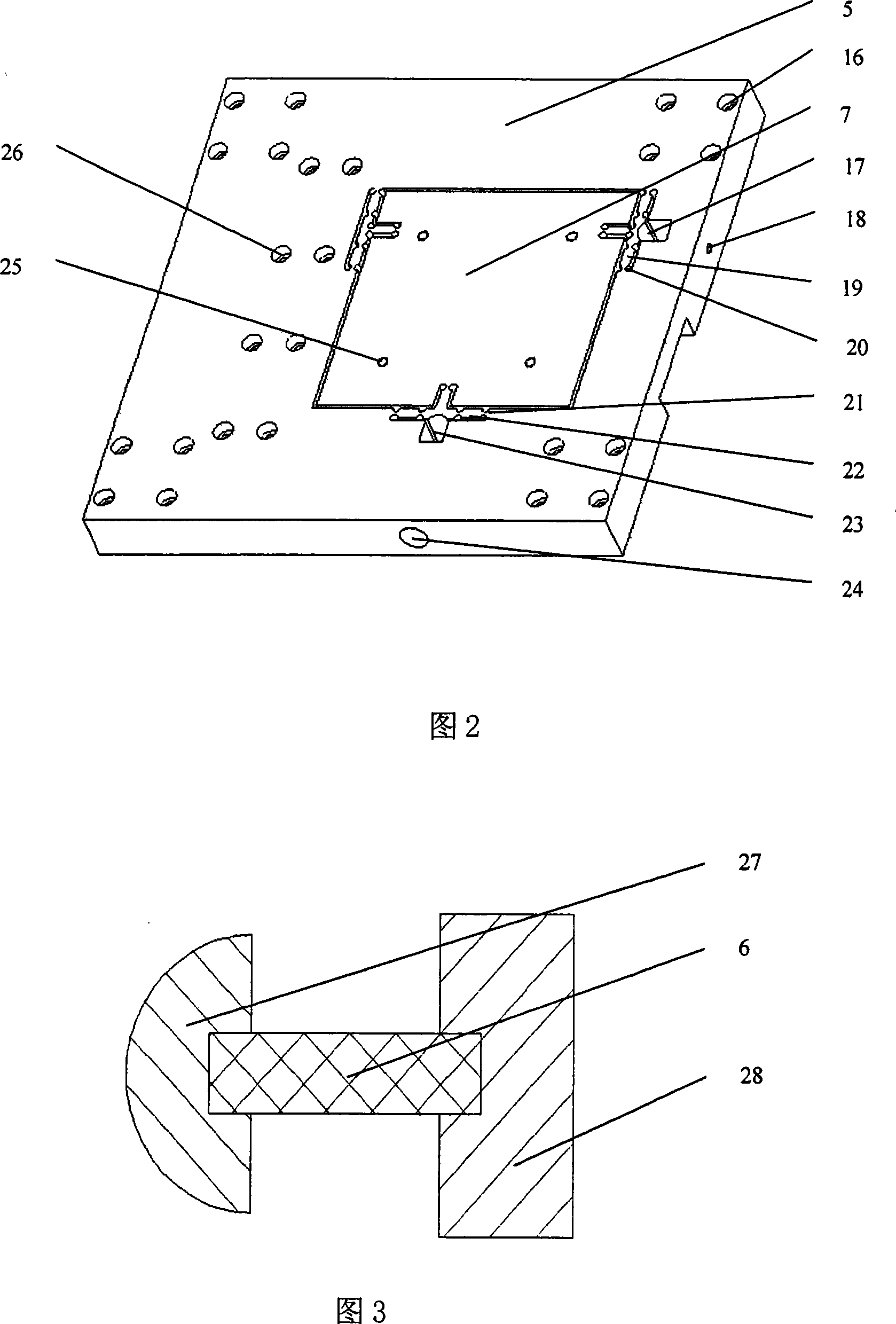

[0012] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Referring to Fig. 1, the coarse motion platform of the present invention uses a linear motor to directly drive the base of the upper platform to achieve a wide range of high-speed motion. Coarse movement platform consists of lower platform base 1, linear motor stator 2, guide rail 3, rolling guide pair 4, upper platform base 5, micro-motion working platform 7, grating ruler reading head 8, connecting frame 9, grating ruler 10, installation The fixed frame 11 of the grating ruler, the mechanical limit device 13, the linear motor mover 14, and the linear motor mover connecting frame 15; the lower platform base 1 is equipped with two parallel guide rails 3, and the upper platform base 5 passes through the rolling guide rail pair 4 Installed on the two parallel guide rails 3 of the lower platform, the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com