Low temperature curing epoxy coating and preparation method thereof

An epoxy coating, low temperature technology, applied in the field of coatings, can solve the problems of slow reaction, inability to achieve winter construction, etc., and achieve the effects of fast hydrolysis and crosslinking, improving storage stability, and improving dryness and crosslinking density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

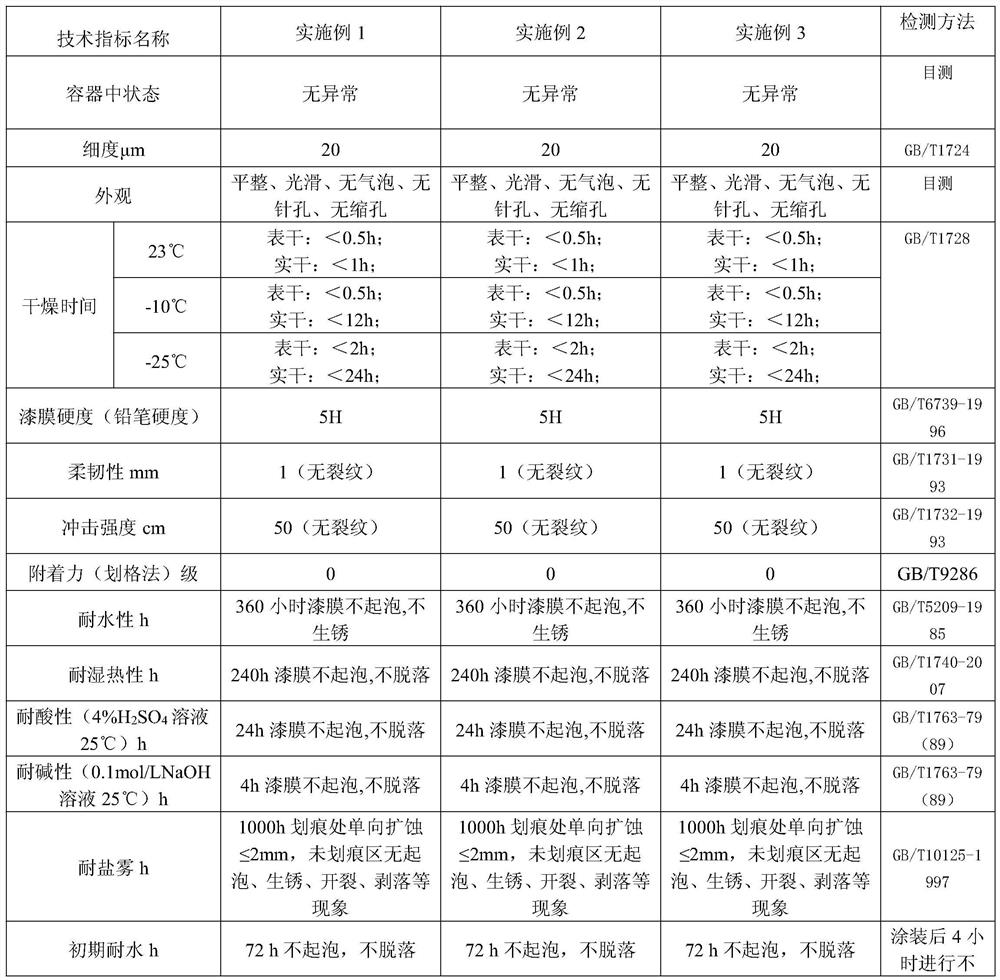

Examples

Embodiment 1-3

[0024] Prepare silane-modified epoxy resin according to the following formula:

[0025] E20 epoxy resin: 35, E44 epoxy resin: 22, xylene: 11, butanol: 5, absolute ethanol: 5, N-(n-butyl)-γ-aminopropyltrimethoxysilane: 40.

[0026] Silane-modified epoxy resin is prepared by the following method:

[0027] Add E20 epoxy resin, E44 epoxy resin, xylene, and butanol into the reaction tank, stir evenly, add N-(n-butyl)-γ-aminopropyltrimethoxysilane, and heat up to 50°C for 6 hours , lower the temperature to below 25°C and add absolute ethanol to obtain a silane-modified epoxy resin.

[0028] The above-mentioned silane-modified epoxy resins were used to prepare low-temperature curing epoxy coatings.

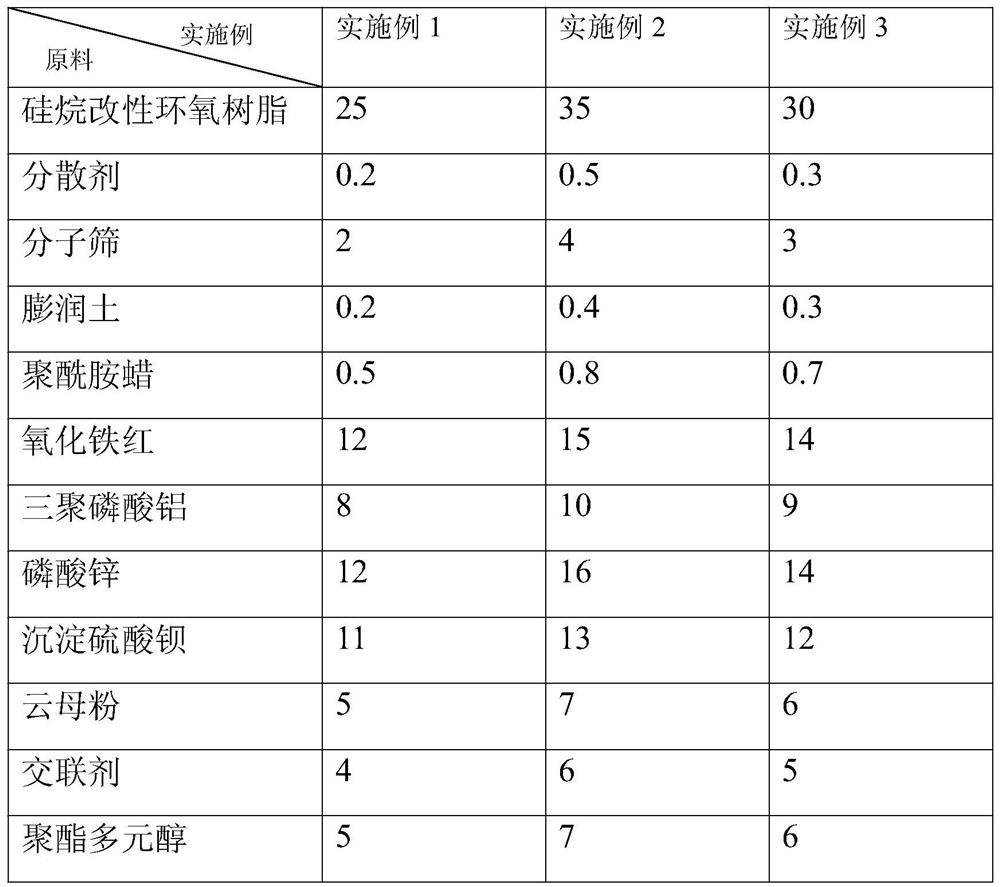

[0029] Embodiment 1-3 component A raw material parts by weight are shown in the following table:

[0030]

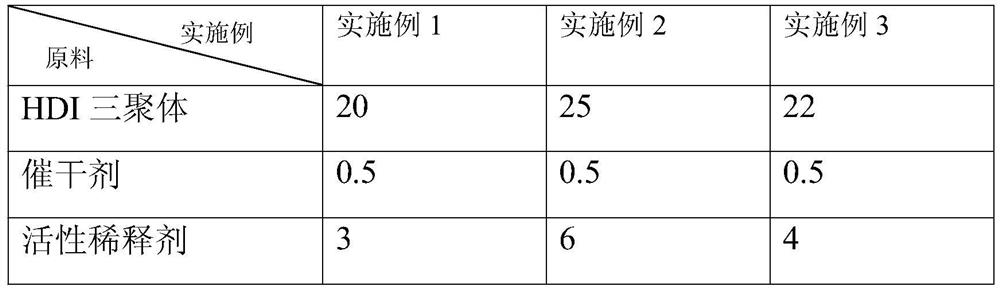

[0031] Embodiment 1-3 component B raw material parts by weight are shown in the following table:

[0032]

[0033] The crosslinking agent is vinyltrimethoxysilane. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com