Method for synthesizing polyimide precursor polymer resin and method for manufacturing single-sided flexible copper-clad plates

A polyimide and resin synthesis technology, applied in the field of microelectronic materials, can solve the problem of low peel strength of non-adhesive flexible single-sided flexible copper clad laminates, three-layer glued flexible boards whose dimensional change rate is greatly affected by temperature, and low peel strength and other issues, to achieve the effect of increasing dependence and application range, enhancing long-term reliability, and reducing ion mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

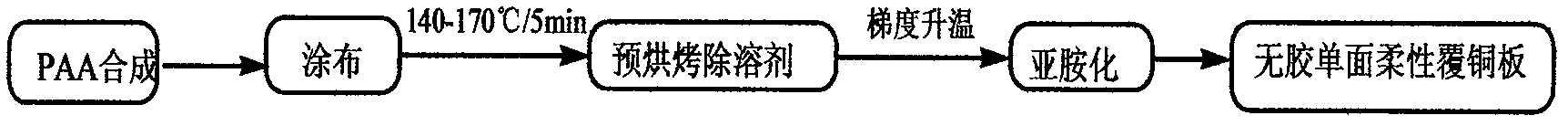

Method used

Image

Examples

Embodiment 1

[0079] Add 216 grams of DMAc to a three-neck vessel with nitrogen gas, then add 6.1 grams (0.03 moles) of ODA and 7.6 grams (0.07 moles) of PPDA, stir and dissolve completely at 50 ° C, and then add 0.5 grams of silane coupling reagent KBM-603 After stirring for 30 minutes, add 5.5 grams (0.025 moles) of PMDA at 0°C (ice-water bath), add 19.8 grams (0.07 moles) of BPDA after stirring for 1.5 hours, and continue stirring for 6 hours to obtain polyimide prepolymer resin , Standing defoaming, the measured resin solid content is 16.2%, and the viscosity is 14200CPS.

[0080] Coat the above-mentioned polyimide prepolymer resin on JE BHY-22BT type 1 / 2oz RA Copper, pre-bake it in an oven at 160°C / 5 minutes, remove the solvent, and then heat it at a high temperature under nitrogen protection In a non-oxidizing oven, the temperature is gradually increased at 80°C / 30 minutes, 120°C / 60 minutes, 160°C / 30 minutes, 200°C / 30 minutes, 250°C / 30 minutes, 300°C / 20 minutes, 330°C / 30 minutes , so...

Embodiment 2

[0082] In a three-necked container with nitrogen, add 327 grams of DMF, then add 12.1 grams (0.06 moles) of ODA and 16.4 grams (0.04 moles) of BAPP, stir and dissolve completely at room temperature, and then add 0.9 grams of silane coupling reagent KBM-403 After stirring for 30 minutes, add 9.7 grams (0.03 moles) of BTDA at 0°C (ice-water bath), add 20.6 grams (0.07 moles) of BPDA after stirring for 2 hours, and continue stirring for 7 hours to obtain a polyimide prepolymer resin , standing defoaming, the measured solid content of the resin is 15.8%, and the viscosity is 13700CPS.

[0083] Coat the above-mentioned polyimide prepolymer resin on JE JTCS type 1 / 2oz ED Copper, pre-bake it in an oven at 160°C / 5 minutes to remove the solvent, and then put it under the protection of nitrogen at high temperature without oxidation In the oven, the temperature is gradually increased at 80°C / 30 minutes, 120°C / 60 minutes, 160°C / 30 minutes, 200°C / 30 minutes, 250°C / 30 minutes, 300°C / 20 minu...

Embodiment 3

[0085] In a three-necked container with nitrogen gas, add 219 grams of NMP, then add 8.7 grams (0.08 moles) of PPDA and 5.8 grams (0.02 moles) of TPER, stir and dissolve completely at 50 ° C, and then add 0.8 grams of silane coupling reagent KBM- 603, after stirring for 30 minutes, add 25 grams (0.085 moles) of BPDA at 0°C (ice-water bath), add 6.2 grams (0.02 moles) of ODPA after stirring for 2 hours, and continue stirring for 8 hours to obtain a polyimide prepolymer Resin, standing defoaming, measured resin solid content is 17.3%, viscosity is 17500CPS.

[0086] Coat the above-mentioned polyimide prepolymer resin on "Fukuda 1 / 2oz ED Copper", pre-bake it in an oven at 170°C / 10 minutes to remove the solvent, and then place it in a high-temperature non-oxidizing oven under nitrogen protection to 80°C / 30 minutes, 120°C / 60 minutes, 160°C / 30 minutes, 200°C / 30 minutes, 250°C / 30 minutes, 300°C / 20 minutes, 350°C / 30 minutes to make imide After complete melting, an adhesive-free singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com