Ellipse core panda type polarization maintaining optical fiber and manufacturing method thereof

A polarization-maintaining optical fiber and a production method technology, applied in the directions of light guides, optics, optical components, etc., can solve the problem that the optical fiber cannot be integrated, and achieve the effect of not easy to crack in the stress area, strong birefringence performance, and reducing the volume of the gyroscope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

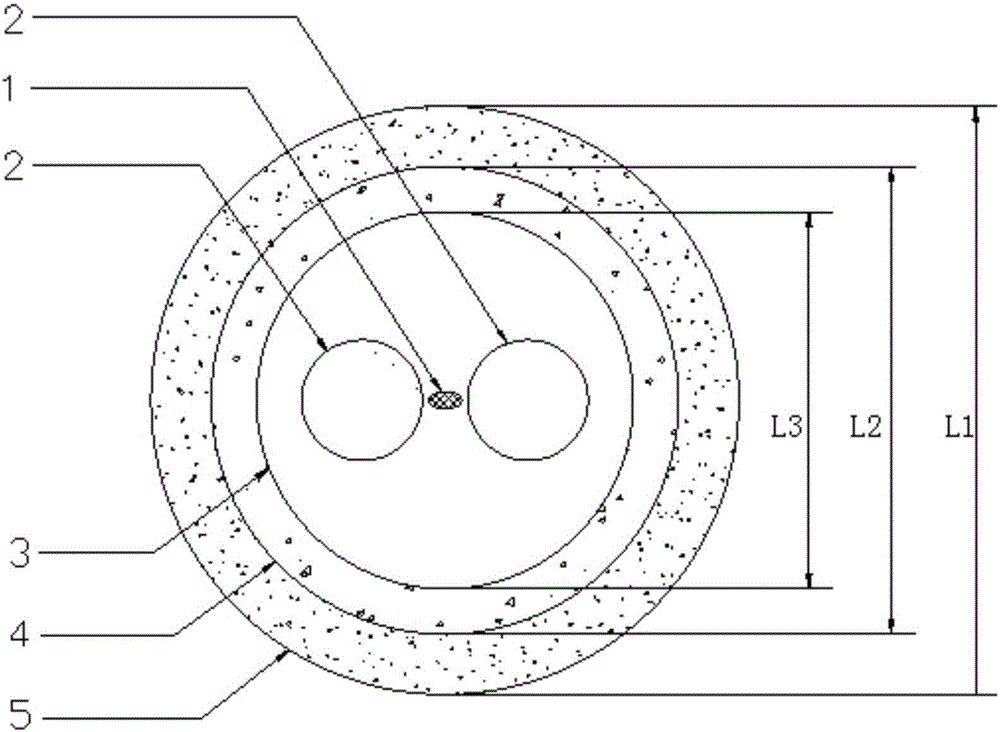

[0043] Embodiment 1: The manufacturing method of elliptical-core panda-type polarization-maintaining optical fiber comprises the following steps:

[0044] Step 1, using Chemical Vapour Deposition (CVD) technology to prepare mandrels, using Modified Chemical Vapour Deposition (MCVD) or Furnace Chemical Vapor Deposition (FCVD) to prepare large core diameter and high numerical aperture Numerical Aperture (NA) mandrels, according to the core diameter and numerical aperture NA controls the mode field diameter and cut-off wavelength of the fiber;

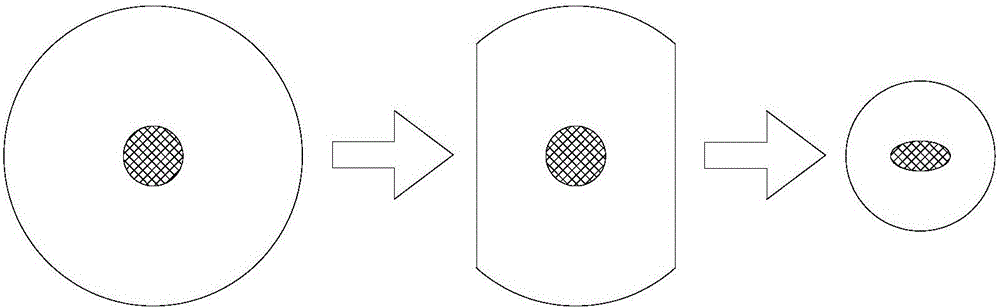

[0045] Step 2: The mandrel is flattened and stretched. After the periphery of the mandrel is ground to a suitable size, the long and short axes are flattened according to different proportions, and then stretched. During the stretching process, the core area changes from circular to elliptical, and the outer circle becomes Round, according to the ratio of flat grinding to control the ratio of the long and short axes of the fiber core diam...

Embodiment 2

[0049] Embodiment 2: The manufacturing method of elliptical-core panda-type polarization-maintaining optical fiber comprises the following steps:

[0050] Step 1, using CVD technology to prepare the core rod, preparing a large core diameter and high numerical aperture NA core rod, and controlling the mode field diameter and cut-off wavelength of the optical fiber according to the core diameter and numerical aperture NA;

[0051] Step 2: The mandrel is flattened and stretched, and the periphery of the mandrel is ground to a suitable size, and then stretched to a suitable size;

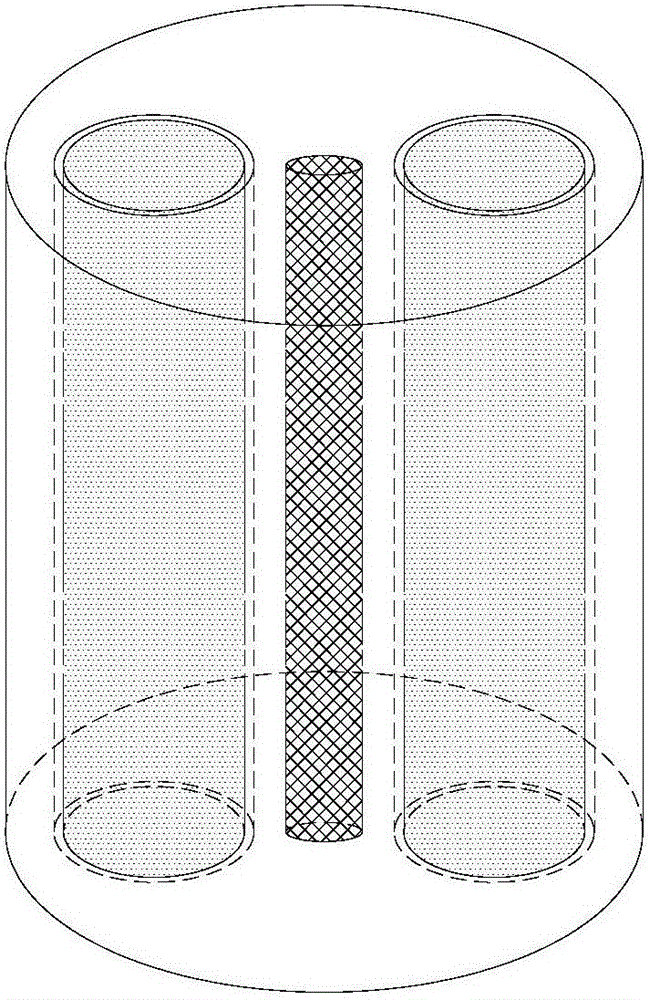

[0052] Step 3, melting and punching and shaping, select a suitable diamond-shaped sleeve for melting and shrinking, punch holes in the long axis direction according to different spacings after melting, and then shape in the short axis direction to ensure the roundness of the optical fiber cladding, and adjust according to the hole spacing Fiber stress birefringence performance and attenuation;

[0053]...

Embodiment 3

[0055] Embodiment 3: The manufacturing method of elliptical-core panda-type polarization-maintaining optical fiber comprises the following steps:

[0056] Step 1, using CVD technology to prepare a core rod, using MCVD or FCVD to prepare a large core diameter and high numerical aperture NA core rod, and controlling the mode field diameter and cut-off wavelength of the optical fiber according to the core diameter and numerical aperture NA;

[0057] Step 2: The mandrel is flattened and stretched. After the periphery of the mandrel is ground to a suitable size, the long and short axes are flattened and ground according to different proportions, and then stretched. During the stretching process, the core area becomes elliptical and the outer circle becomes round. According to the flat grinding ratio, the ratio of the long and short axes of the fiber core diameter is controlled, thereby controlling the additional beat length;

[0058] Step 3, pure silicon rods are drilled and shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com