A kind of polycarbonate and its synthesis method, rigid monomer and its preparation method

A technology of polycarbonate and synthesis method, which is applied in the preparation of carboxylic acid esters, carbon-based compounds, hydroxyl compounds, etc., and can solve problems such as poor yellowing resistance, cancer induction, precocious puberty in infants, and lack of weather resistance. , to achieve the effect of good sustainable development, easy structure and function, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

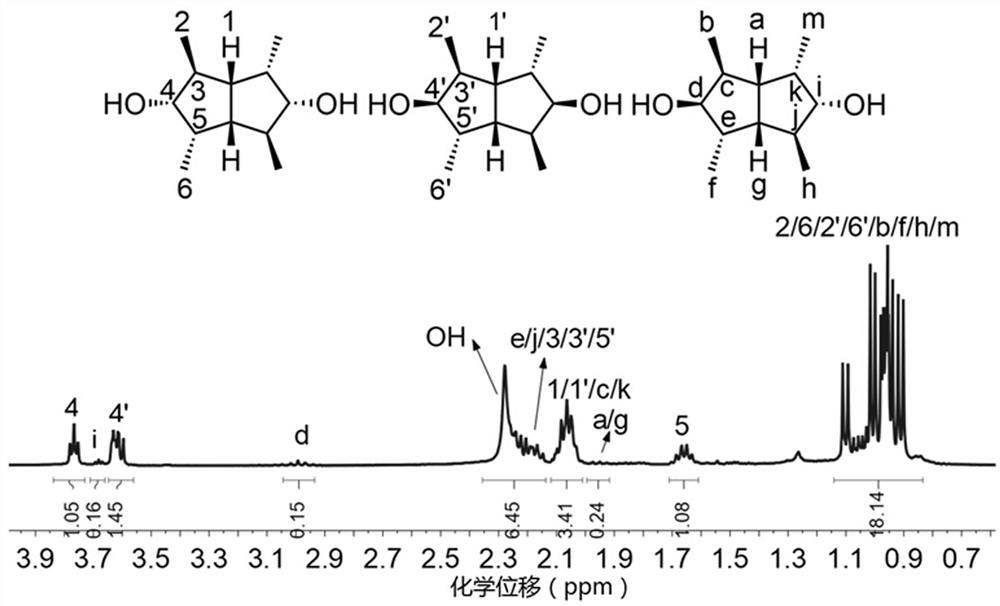

[0070] This example provides a preparation method for the compound (2,4,6,8-tetramethylbicyclo[3.3.0]octane-3,7-diol) represented by formula (I), and its synthetic route is as follows, wherein M is sodium:

[0071]

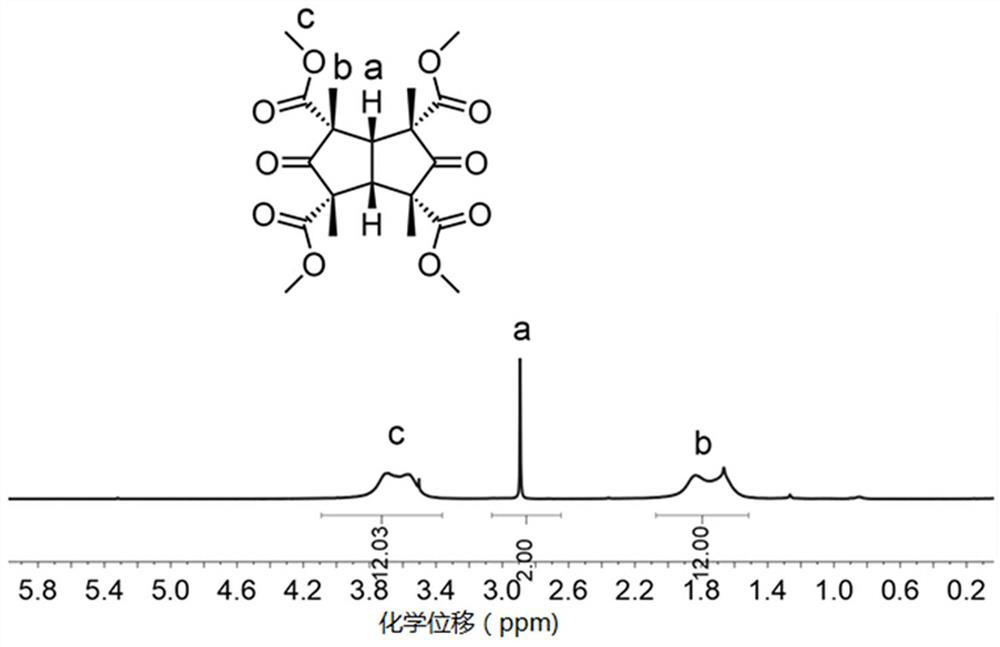

[0072] (1) Under ice bath, add 125 mL of methanol to a 500 mL round-bottomed flask equipped with a magnetic stirrer, slowly add 7.04 g (0.176 mol) of NaOH, and slowly dropwise add 30 g (0.172 mol) of 1.3- Dimethyl acetonedicarboxylate, heated to reflux at 65°C for 4 h, added 5.7 g (0.098 mol) glyoxal, reacted at room temperature for 12 h, filtered with suction, washed with 30 mL of methanol, dried to obtain the compound represented by formula (Ⅴ) , the yield is about 70%.

[0073] (2) Dissolve the compound represented by formula (Ⅴ) obtained in step (1) in distilled water, add hydrochloric acid (1mol / L) to acidify, then extract with ethyl acetate, wash with saturated sodium bicarbonate solution, anhydrous Na 2 SO 4 After drying and spin-drying ethyl acetate,...

Embodiment 2

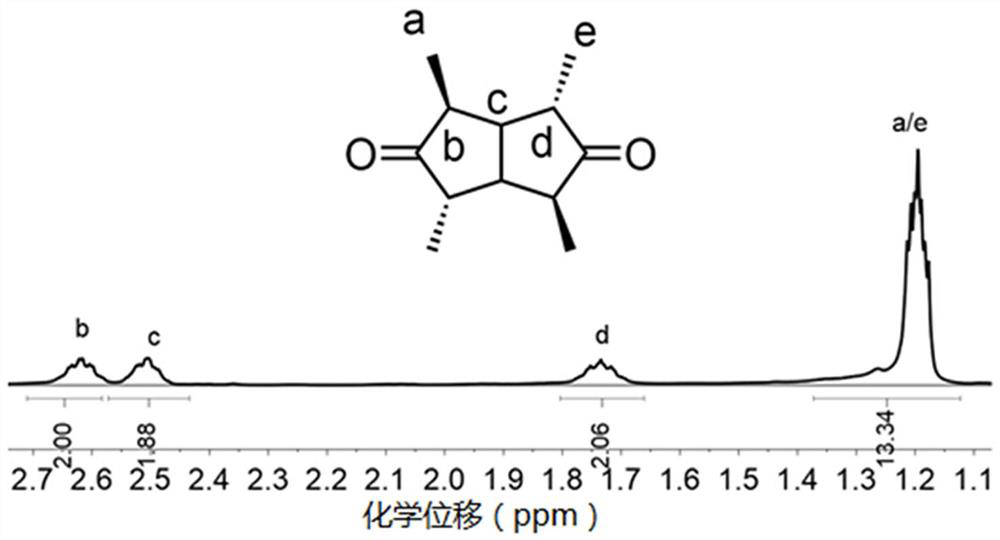

[0077] This example provides a preparation method of the compound (2,4,6,8-tetramethylbicyclo[3.3.0]octane-3,7-diol) represented by formula (I), which includes the following steps:

[0078] The steps for preparing the compound represented by formula (II) are the same as in Example 1.

[0079] Under ice-bath conditions, add 5.0 g of the compound represented by formula (II) into a round-bottomed flask equipped with a stirring magnet, add 100 mL of anhydrous methanol, 0.10 mol of sodium borohydride, and react at 0°C for 8 h. Continue to react for 4 h. After the reaction, add 50 mL of distilled water, 125 mL (2 M) of hydrochloric acid, extract with 4×50 mL of ethyl acetate, dry over anhydrous magnesium sulfate, filter with suction, and rotary evaporate to obtain the rigid single 2,4,6,8-tetramethylbicyclo[3.3.0]octane-3,7-diol with a yield of 85%.

Embodiment 3

[0081] This example provides a kind of preparation method of homopolycarbonate, and it comprises the steps:

[0082] Add 1.98 g (10 mmol) of 2,4,6,8-tetramethylbicyclo[3.3.0]octane-3,7-diol prepared in Example 1 and 2.14 g (10 mmol) diphenyl carbonate, add catalyst lithium acetylacetonate and 4-dimethylaminopyridine (mass ratio of feed is 1:1, total feed 0.015 g), slowly feed nitrogen and continue stirring, heat to 140 ° C, at this temperature React for 3 h. The nitrogen protection was removed, the vacuum was changed to 0.5 mmHg, the temperature was raised to 200°C, and the reaction was continued for 8 h. The reaction solution was cooled to room temperature, dissolved by adding 2 mL of chloroform, precipitated by cold methanol, and a light yellow solid was precipitated, which was filtered by suction and fully dried to obtain homopolycarbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com