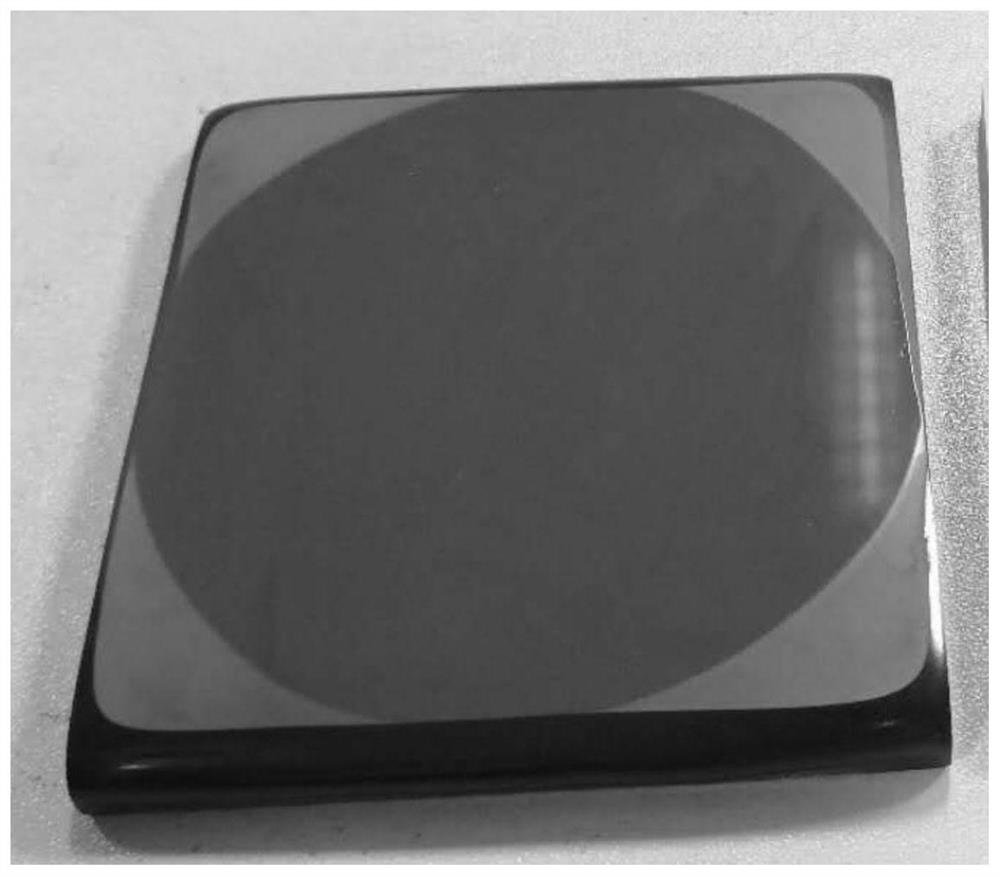

Coffee microcrystalline glass stone prepared from molybdenum tailings and preparation method of coffee microcrystalline glass stone

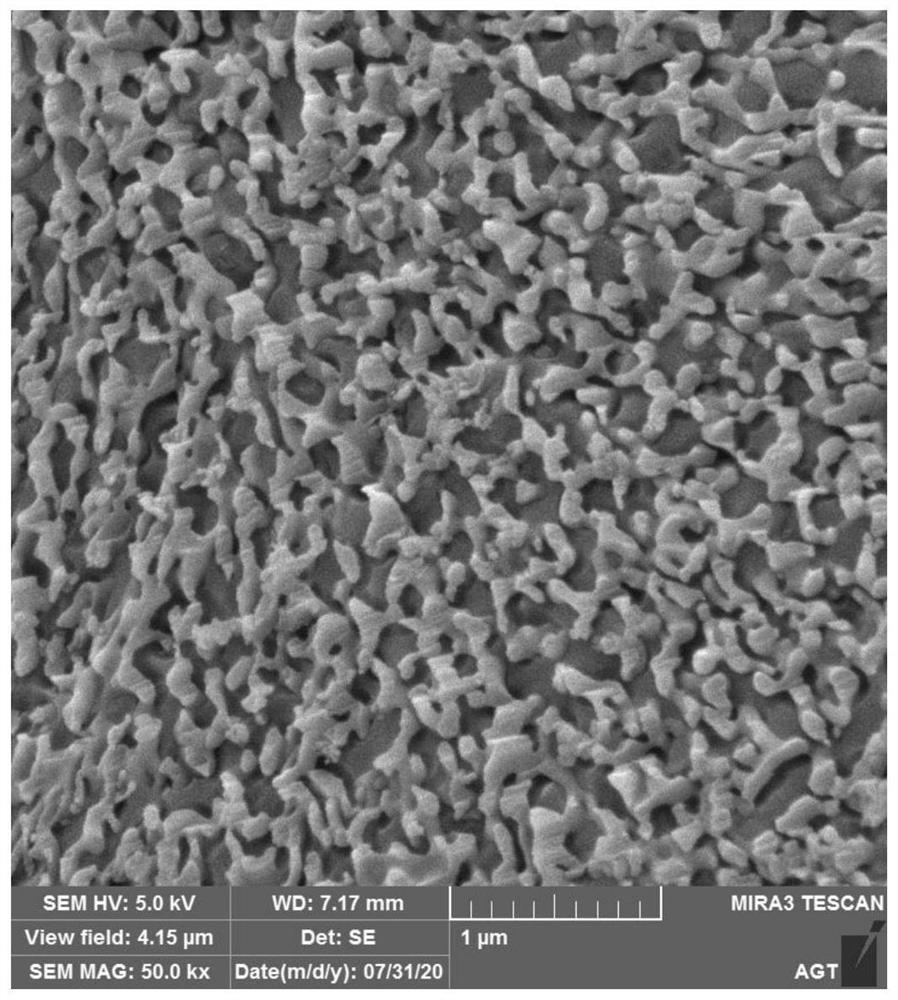

A technology for glass-ceramic and molybdenum tailings, which is applied in glass manufacturing equipment, glass forming, manufacturing tools, etc., can solve the problem of impurity in color and texture of glass-ceramic, limiting the application range of glass-ceramic, and poor crystallization effect. and other problems, to achieve the effect of high flexural strength, dense microstructure and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A brown glass-ceramic stone prepared from molybdenum tailings, comprising the following raw materials: by mass percentage, molybdenum tailings 50%, limestone 26%, dolomite 9.0%, silica sand 5.5%, sodium fluorosilicate 4.2%, chromium Iron ore powder 3.5%, titanium dioxide 1.8%.

[0034] A method for preparing a brown glass-ceramic stone prepared from molybdenum tailings, comprising the following steps:

[0035] (1) Preheating: After mixing molybdenum tailings, limestone, dolomite, silica sand, sodium fluorosilicate, chromite powder and titanium dioxide evenly, pour it into a quartz crucible that has been preheated to 800°C, and place it in the same Keep the quartz crucible in an isothermal high-temperature furnace for 35 minutes to fully preheat the mixture;

[0036] (2) Melt molding: heat the preheated raw material to 1490°C at a rate of 10°C / min and keep it warm for 2 hours, then pour the obtained molten glass on the mold and press for molding;

[0037] (3) Nucleatio...

Embodiment 2

[0040] A brown glass-ceramic stone prepared from molybdenum tailings, comprising the following raw materials: by mass percentage, molybdenum tailings 52%, limestone 26.7%, dolomite 8.6%, silica sand 4.0%, sodium fluorosilicate 4.0%, chromium Iron ore powder 3.1%, titanium dioxide 1.6%.

[0041] A method for preparing a brown glass-ceramic stone prepared from molybdenum tailings, comprising the following steps:

[0042] (1) Preheating: After mixing molybdenum tailings, limestone, dolomite, silica sand, sodium fluorosilicate, chromite powder and titanium dioxide evenly, pour it into a quartz crucible that has been preheated to 850°C, and place it in the same Keep the quartz crucible in an isothermal high-temperature furnace for 30 minutes to fully preheat the mixture;

[0043] (2) Melt molding: heat the preheated raw material to 1500°C at a rate of 10°C / min and keep it warm for 2 hours, then pour the obtained molten glass on the mold and press for molding;

[0044] (3) Nucleat...

Embodiment 3

[0047] A brown glass-ceramic stone prepared from molybdenum tailings, comprising the following raw materials: by mass percentage, molybdenum tailings 53%, limestone 27%, dolomite 8.0%, silica sand 3.0%, sodium fluorosilicate 4.5%, chromium Iron ore powder 3.0%, titanium dioxide 1.5%.

[0048] A method for preparing a brown glass-ceramic stone prepared from molybdenum tailings, comprising the following steps:

[0049] (1) Preheating: After mixing molybdenum tailings, limestone, dolomite, silica sand, sodium fluorosilicate, chromite powder and titanium dioxide evenly, pour it into a quartz crucible that has been preheated to 900°C, and place it in the same Keep the quartz crucible in an isothermal high-temperature furnace for 25 minutes to fully preheat the mixture;

[0050] (2) Melt molding: heat the preheated raw material to 1510°C at a rate of 10°C / min and keep it warm for 2 hours, then pour the resulting molten glass on the mold and press to form it;

[0051] (3) Nucleatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com