Polyolefin-based adhesive composition

A composition and adhesive technology, applied in the direction of grafted polymer adhesives, adhesive types, polymer adhesive additives, etc., can solve the reduction of lamination strength, electrolyte leakage, corrosion barrier, etc. problems, to achieve the effect of low heat shrinkage effect, good adhesion and chemical resistance, excellent adhesion and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

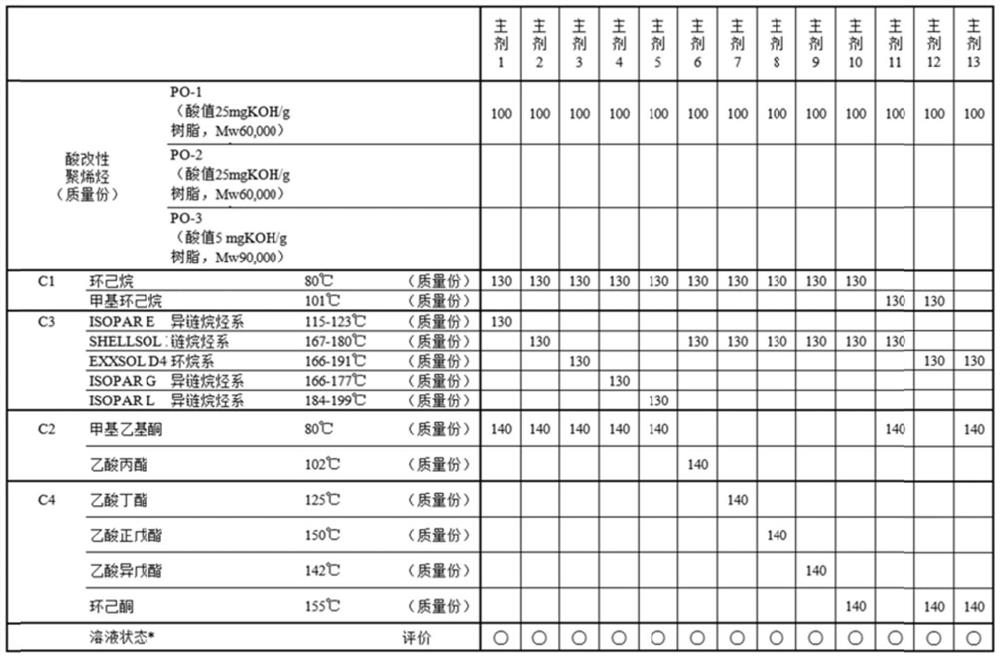

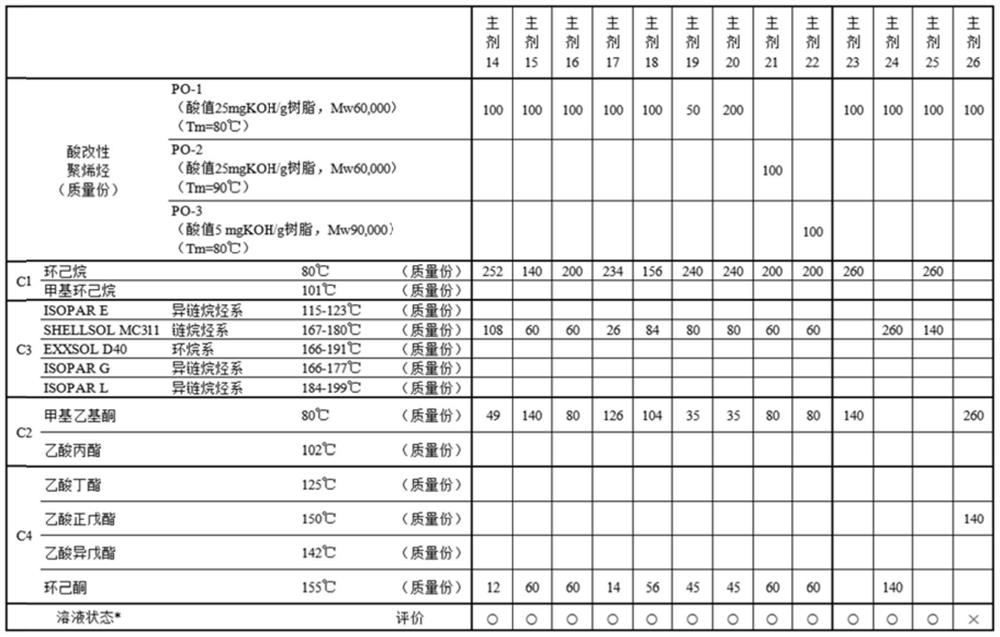

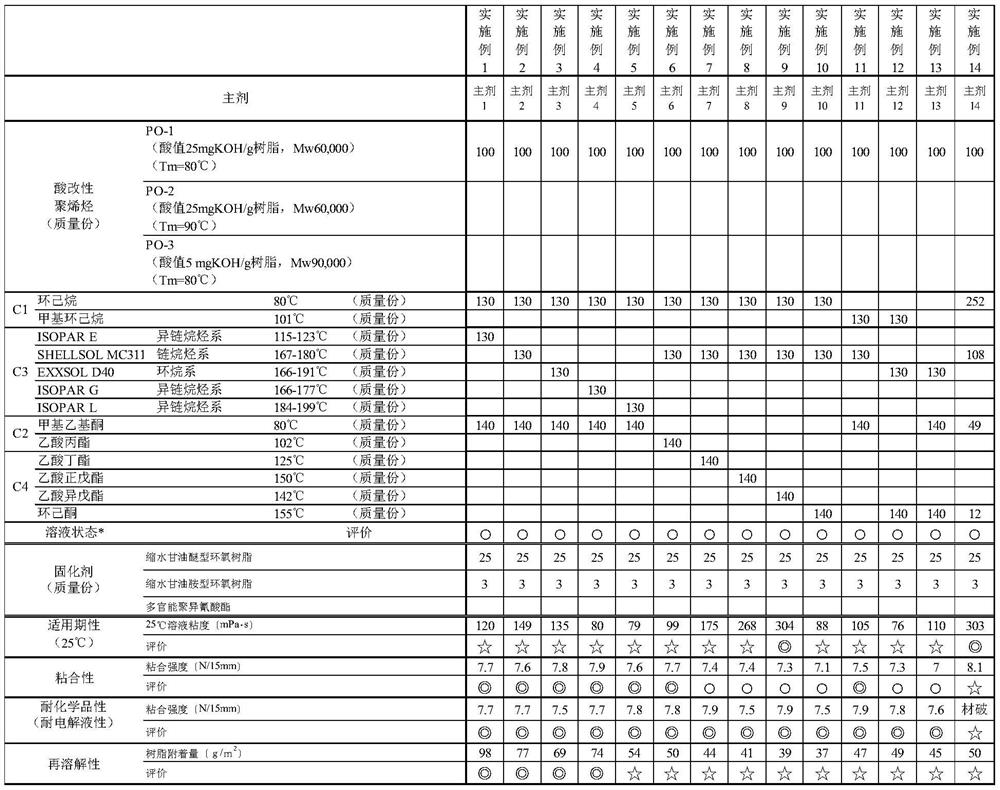

Method used

Image

Examples

Embodiment

[0083]Examples are given below to illustrate the present invention in more detail. However, this invention is not limited to an Example.

manufacture example 1

[0086] Add 100 parts by mass of propylene-butene copolymer (Tm: 80°C), 233 parts by mass of toluene, 20 parts by mass of maleic anhydride, and 5 parts by mass of di-tert-butyl peroxide into a 1L autoclave, and heat up to 140°C , and further stirred for 1 hour (herein, referred to as "reaction" for 1 hour). Then, after cooling the obtained reaction liquid to 100° C., it was poured into a container previously heated to 40° C. containing 717 parts by mass of toluene and 950 parts by mass of methyl ethyl ketone while stirring, cooled to 40° C., and further stirred for 30 minutes. Further cooling to 25° C. precipitates a resin (here, the operation of pouring the reaction liquid into a solvent such as methyl ethyl ketone while stirring, and cooling to deposit a resin is called “reprecipitation”). Then, by centrifuging the slurry containing the resin, the acid-modified propylene-butene copolymer graft-polymerized with maleic anhydride was separated from (poly)maleic anhydride and low...

manufacture example 2

[0090] The propylene-butene copolymer (Tm: 80°C) used in Production Example 1 was changed to a propylene-butene copolymer (Tm: 90°C), the number of repulping was changed to one, and the amount of methyl ethyl ketone added during repulping The amount of is changed to 1000 mass parts, except that, carry out similarly with manufacture example 1, obtain the maleic anhydride modified propylene-butene copolymer (PO-2, acid value 25mgKOH / g resin of acid-modified polyolefin) , weight average molecular weight 60,000, Tm90°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com