Embedded polymer/metal grid flexible transparent electrode and its preparation method and application

A technology of transparent electrodes and metal grids, which is applied in the manufacture of cables/conductors, circuits, electrical components, etc., can solve the complex preparation and processing process of carbon nanotubes and graphene, the haze of metal nanowires is large, and the preparation process is complex and expensive. and other problems, to achieve the effect of overcoming the mutual restriction of electrical conductivity and light transmittance, good optoelectronic properties and mechanical stability, and overcoming the high cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

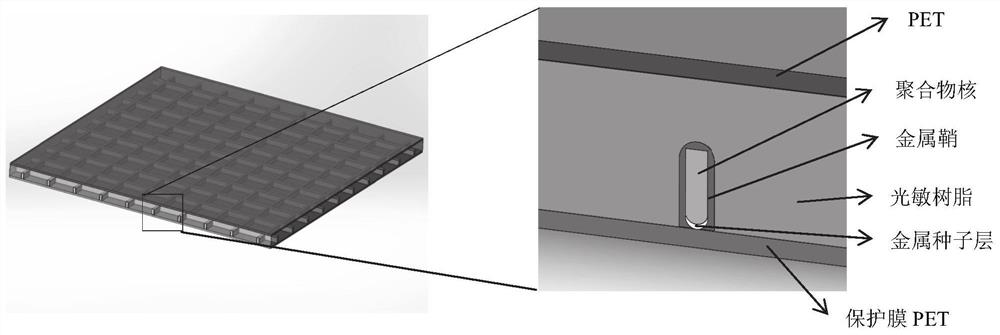

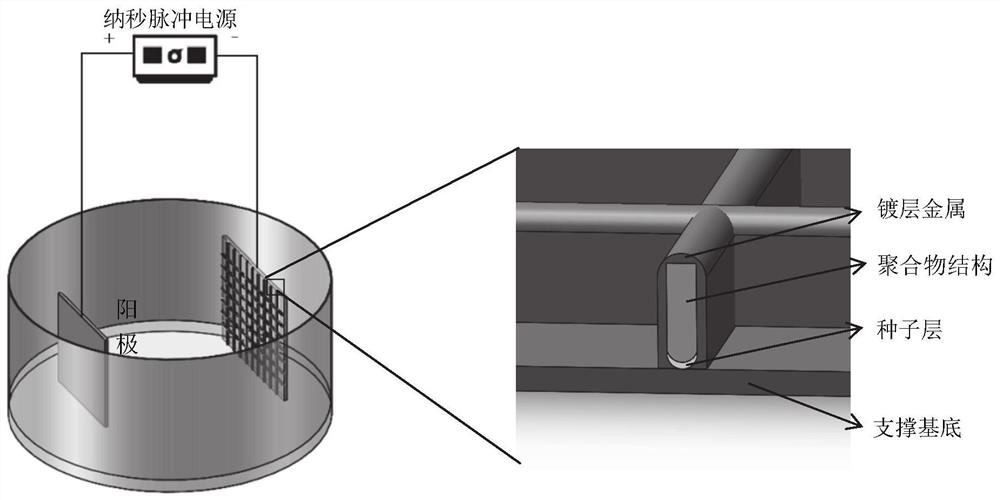

[0070] figure 1 It is a schematic diagram of an embedded PCL / Ni flexible grid transparent electrode to be manufactured by the present invention, and its structure is as shown in the figure. The parameters of the PCL / Ni flexible mesh transparent electrode to be manufactured in this example are: line width 5 μm, period 100 μm, and aspect ratio 5:1.

[0071] Taking the embedded PCL / Ni flexible mesh transparent electrode described in the implementation example as an example, combined with Figure 1-Figure 6 , which specifies the specific process of fabricating embedded PCL / Ni flexible mesh transparent electrodes based on the proposed method and device.

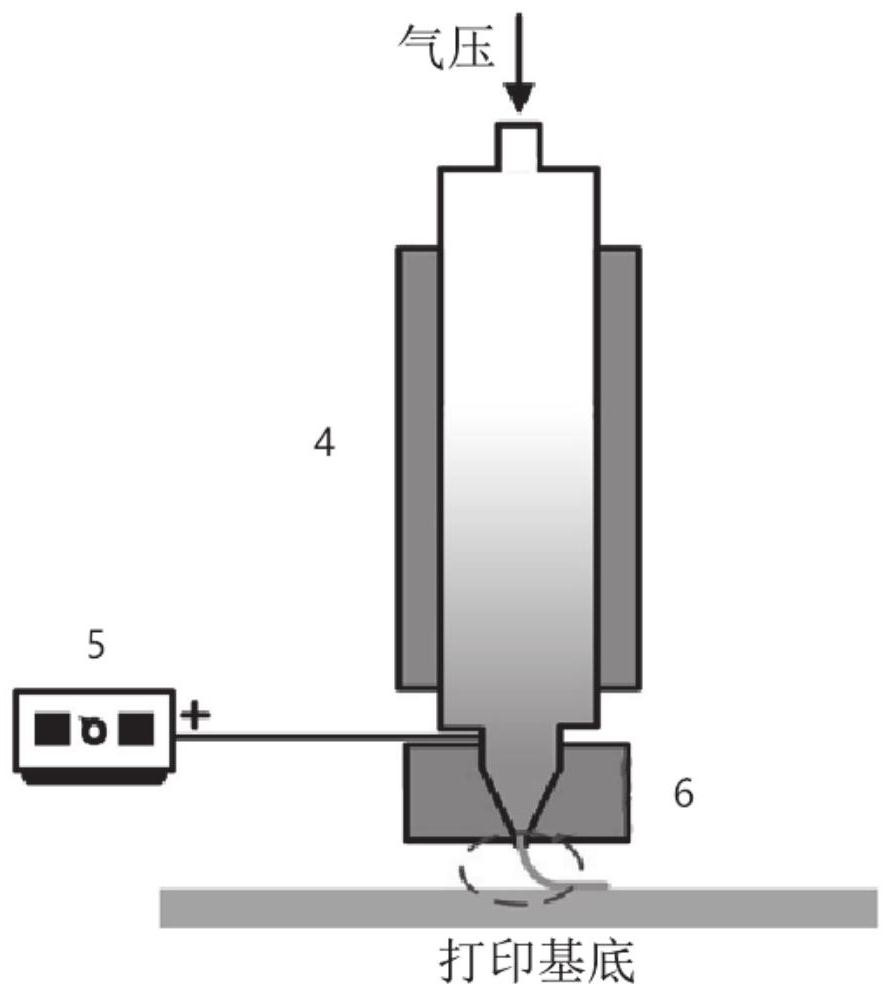

[0072] Step 1: Print the PCL ordered grid structure.

[0073] The self-developed electric field-driven melt jet deposition micro-nano 3D printer was used to print a large aspect ratio, narrow linewidth polycaprolactone (PCL) ordered grid on a glass substrate spin-coated with a polyvinyl alcohol (PVA) film. The overall size of t...

Embodiment 2

[0098] The parameters of the embedded PCL / Cu flexible mesh transparent electrode to be fabricated in this example are: line width 8 μm, period 100 μm, and aspect ratio 5:1.

[0099] The specific process of fabricating embedded PCL / Cu flexible mesh transparent electrodes:

[0100] Step 1: Print the PCL ordered grid structure.

[0101] The self-developed electric field-driven melt jet deposition micro-nano 3D printer was used to print a large aspect ratio, narrow linewidth polycaprolactone (PCL) ordered grid on a glass substrate spin-coated with a polyvinyl alcohol (PVA) film. The overall size of the grid in the implementation example is 100×100mm. By controlling the line width and period of PCL, high light transmittance can be achieved. The line width is controlled at 3μm, the period is selected as 100μm, and the aspect ratio is 5:1. Polycaprolactone (Polycaprolactone) produced by Aladdin Company was selected as the printing material.

[0102] Specific process:

[0103] (1) ...

Embodiment 3

[0126] The parameters of an embedded PLA / Cu flexible mesh transparent electrode to be fabricated in this example are: line width 6 μm, period 200 μm, and aspect ratio 4:1.

[0127] The specific process of fabricating embedded PLA / Cu flexible mesh transparent electrodes:

[0128] Step 1: Print the PLA ordered grid structure.

[0129] Using a self-developed electric field-driven melt jet deposition micro-nano 3D printer to print a large aspect ratio, narrow linewidth polylactic acid (PLA) ordered grid on a glass substrate spin-coated with a polyvinyl alcohol (PVA) film, this example The overall size of the grid is 100 × 100 mm. By controlling the line width and period of PLA, high light transmittance can be achieved. The line width is controlled at 3 μm, the period is 200 μm, and the aspect ratio is 4:1. The printing material is Polylactic acid produced by Aladdin.

[0130] Specific process:

[0131] (1) Preprocessing. Design the size and line period of the required grid acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com