Water-based paint for lithium ion battery composite diaphragm, lithium ion battery composite diaphragm and lithium ion battery

A technology for lithium-ion batteries and composite diaphragms, applied in secondary batteries, battery pack components, non-polymer adhesive additives, etc., can solve problems such as poor bonding effect, improve bonding effect, and simplify production Process, effect of reducing coating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

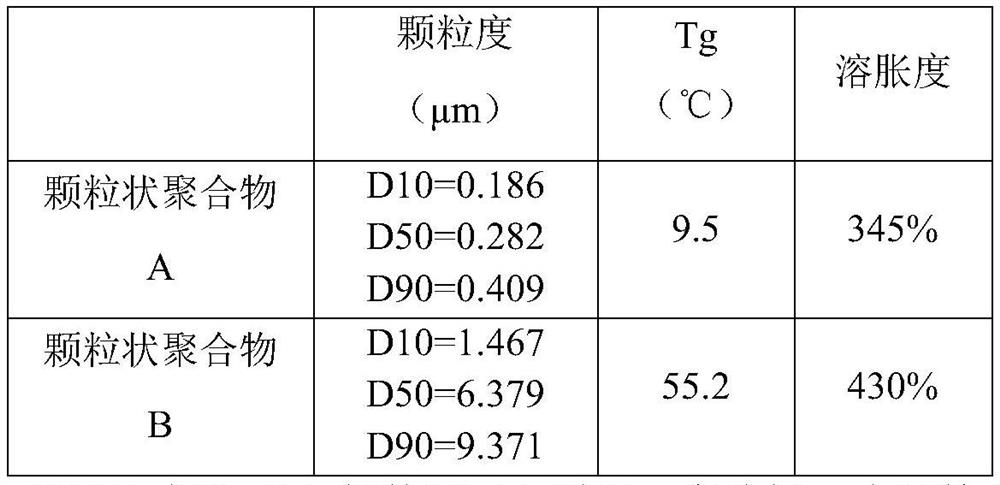

[0083] Preparation of granular polymer A: Weigh 0.64 parts of surfactant and 400 parts of deionized water into a stirring container, add 65 parts of ethyl acrylate, 5 parts of acrylic acid, 10 parts of acrylonitrile, 10 parts of methyl methacrylate, 10 parts of allyl methacrylate, control the stirring speed at 450±50rpm, stir and heat to 74±1°C, then add 1.2 parts of initiator, keep stirring at 74±1°C for 6h, then raise the temperature to 79±1°C, continue to react for 3h , to obtain a granular polymer A emulsion with a solid content of 20%.

[0084] Preparation of Granular Polymer B: Preparation of Granular Polymer B: Add 60 parts of anhydrous MgSO to a stirred vessel 4 powder and 340 parts deionized water, stirred to make 15wt% MgSO 4 400 parts of aqueous solution, add 5 parts of surfactant, 30 parts of methyl methacrylate, 20 parts of acrylonitrile, 40 parts of ethyl acrylate, 10 parts of allyl methacrylate, control the stirring speed at 450±50rpm, stir and heat up to 80 °...

Embodiment 2

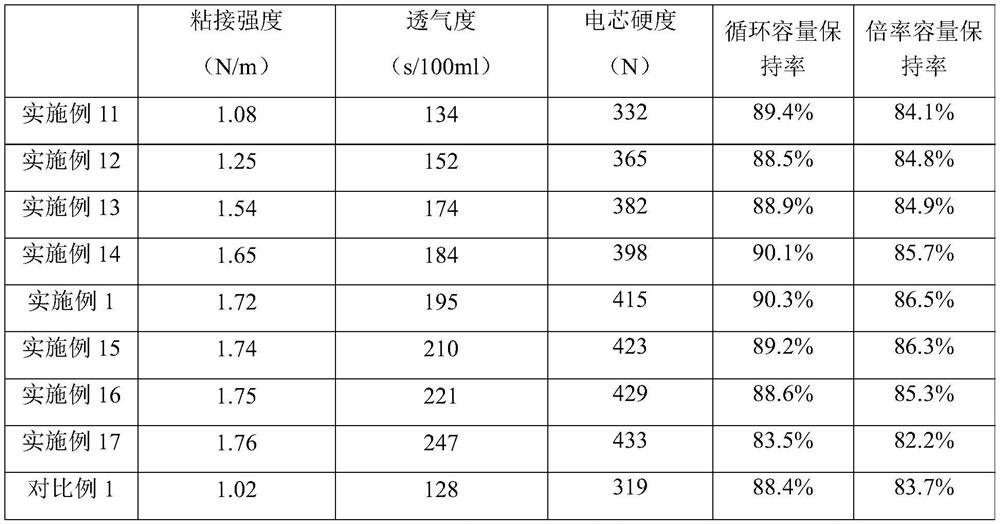

[0090] The difference from Example 1 is that the mass ratio of the granular polymer A emulsion to the granular polymer B emulsion is 0.04:1.

Embodiment 3

[0092] The difference from Example 1 is that the mass ratio of the granular polymer A emulsion to the granular polymer B emulsion is 0.05:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com