Hydroxyl silicone oil modified polyurethane resin, coating and preparation method of hydroxyl silicone oil modified polyurethane resin

A technology of polyurethane resin and hydroxy silicone oil, which is applied in the field of polyurethane resin, can solve the problems of affecting the permeability of the paint film, difficulty in dissolving and uniformly dispersing nano-silica, unsuitable hardness, and scratch resistance, etc., to achieve excellent hydrophobicity, Excellent high temperature resistance, high reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

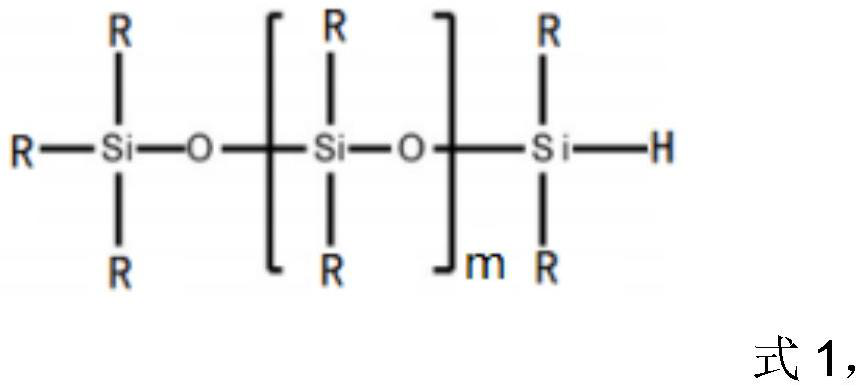

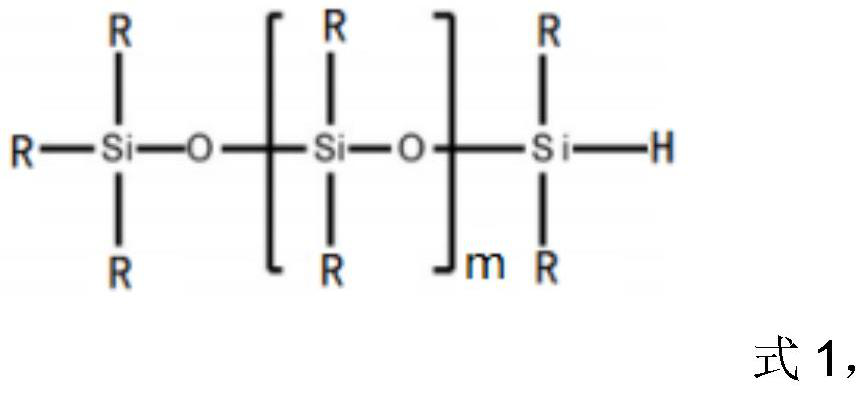

[0066] Under the condition of nitrogen protection, 52g of ethylene glycol monoallyl ether, 55g of buffer solution, 150g of toluene, 500g of hydrogen-terminated silicone oil and 0.26g of 5000ppm Castel platinum catalyst were reacted at 55°C for 6h, then cooled to room temperature, and added After washing with deionized water for 5 times, move it into a separatory funnel to stand for stratification, collect the upper organic layer, and then distill the organic layer under reduced pressure to remove solvent, unreacted reactants or low molecular by-products to obtain hydroxyl silicone oil with a yield of 98 %, the tested viscosity is 20mPa·s, the number average molecular weight is 1100, the hydroxyl content is 50mgKOH / g, and the hydrogen content is 0 after testing; the buffer solution configuration method is as follows: take 50ml0.2mol / L o-phthalic Diformic acid ethanol solution is mixed with 2.6ml of 0.2mol / L hydrogen chloride ethanol solution, and then diluted with ethanol to for...

Embodiment 2

[0070] Under the condition of nitrogen protection, 88g of trimethylolpropane monoallyl ether, 132g of buffer solution, 150g of toluene, 500g of hydrogen-terminated silicone oil and 4.4g of 5000ppm Castel platinum catalyst were reacted at 90°C for 6h, and then cooled to room temperature , add deionized water to wash 5 times, move it into a separatory funnel and let it stand for stratification, collect the upper organic layer, and then distill the organic layer under reduced pressure to remove solvent, unreacted reactants or low molecular by-products to obtain hydroxy silicone oil, the yield It is 99%, its viscosity is 86mPa·s after testing, the number average molecular weight is 1200, the hydroxyl content is 93mgKOH / g, its hydrogen content is 0 after testing; the configuration method of the buffer solution is: take 38ml of 0.1mol citric acid The ethanol solution was mixed with 162 ml of 0.1 mol / L sodium citrate glycerin solution to obtain a 200 ml buffer solution, and the pH val...

Embodiment 3

[0073] Under the condition of nitrogen protection, 66.7g of glycerol allyl ether, 70g of buffer solution, 150g of toluene, 500g of hydrogen-terminated silicone oil and 2g of 5000ppm Castel platinum catalyst were reacted at 80°C for 6h, then cooled to room temperature, and washed with deionized water After 5 times, move it into a separatory funnel and let it stand for stratification, collect the upper organic layer, and then distill the organic layer under reduced pressure to remove solvent, unreacted reactants or low molecular by-products to obtain hydroxy silicone oil with a yield of 99%. The viscosity is 80mPa·s, the number average molecular weight is 1150, the hydroxyl content is 97mgKOH / g, and the hydrogen content is 0 after testing; the buffer solution configuration method is: take 49ml of 0.2mol / L sodium acetate ethanol solution Mix with 51ml of 0.3mol / L acetic acid ethanol solution to obtain 100ml of buffer solution, the pH value is 4.6 at 37°C.

[0074] The preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com