Water-based binder for lithium ion battery diaphragm

A lithium-ion battery, water-based binder technology, used in secondary batteries, binder types, battery pack components, etc., can solve problems such as poor bonding effect of binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

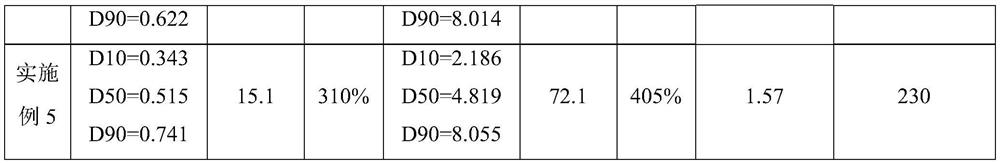

Examples

Embodiment 1

[0067] Preparation of granular polymer A: Weigh 0.64 parts of surfactant and 400 parts of deionized water into a stirring container, add 65 parts of ethyl acrylate, 5 parts of acrylic acid, 10 parts of acrylonitrile, 10 parts of methyl methacrylate, 10 parts of allyl methacrylate, control the stirring speed at 450±50rpm, stir and heat to 74±1°C, then add 1.2 parts of initiator, keep stirring at 74±1°C for 6h, then raise the temperature to 79±1°C, continue to react for 3h , to obtain a granular polymer A emulsion with a solid content of 20%.

[0068] Preparation of Granular Polymer B: Preparation of Granular Polymer B: Add 60 parts of anhydrous MgSO to a stirred vessel 4 powder and 340 parts deionized water, stirred to make 15wt% MgSO 4 400 parts of aqueous solution, add 5 parts of surfactant, 30 parts of methyl methacrylate, 20 parts of acrylonitrile, 40 parts of ethyl acrylate, 10 parts of allyl methacrylate, control the stirring speed at 450±50rpm, stir and heat up to 80 °...

Embodiment 2

[0072] The difference from Example 1 is that the matrix resin ratio used in the preparation of granular polymer A is 65 parts of ethyl acrylate, 5 parts of acrylic acid, 10 parts of acrylamide, 10 parts of methyl methacrylate, 10 parts of methacrylic acid Allyl ester, the matrix resin ratio that adopts in the preparation of granular polymer B is 30 parts of methyl methacrylate, 20 parts of acrylic acid, 40 parts of n-butyl methacrylate, 10 parts of allyl methacrylate.

Embodiment 3

[0074] The difference from Example 1 is that the matrix resin ratio used in the preparation of granular polymer A is 65 parts of ethyl acrylate, 5 parts of acrylonitrile, 10 parts of acrylamide, 10 parts of methyl methacrylate, 10 parts of methyl Allyl acrylate, the matrix resin ratio adopted in the preparation of granular polymer B is 30 parts of acrylic acid, 20 parts of n-butyl methacrylate, 40 parts of allyl methacrylate, and 10 parts of ethyl methacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com