Bismuth strontium titanate-based lead-free ceramic material for efficient capacitor and preparation method of ceramic material

A technology of strontium bismuth titanate and ceramic materials, which can be used in capacitors, fixed capacitors, fixed capacitor dielectrics, etc., can solve problems such as affecting energy storage density, low breakdown strength, and limiting the application of strontium bismuth titanate ceramics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

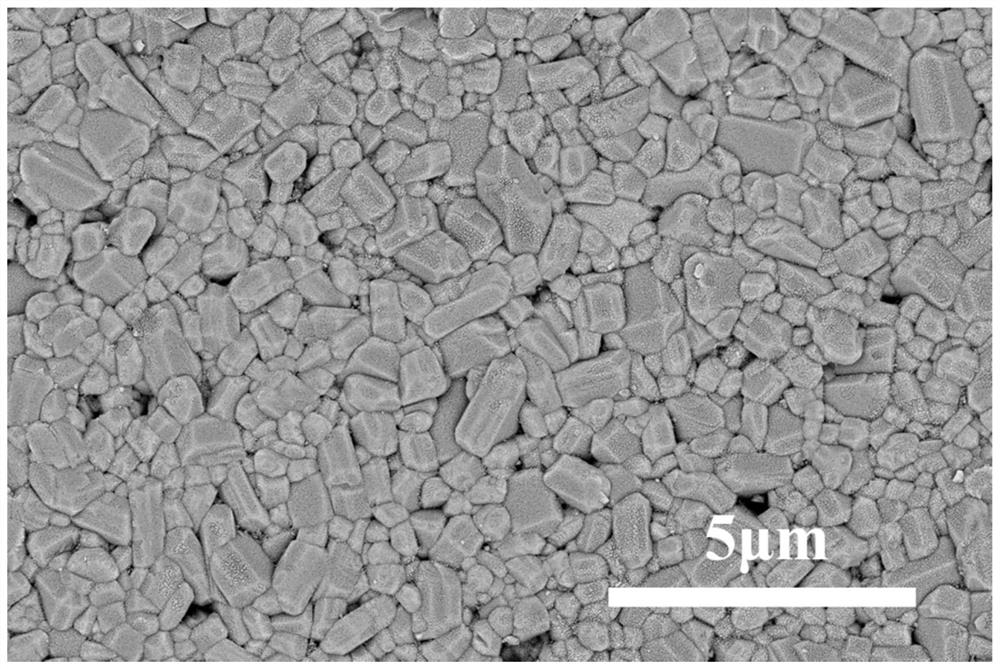

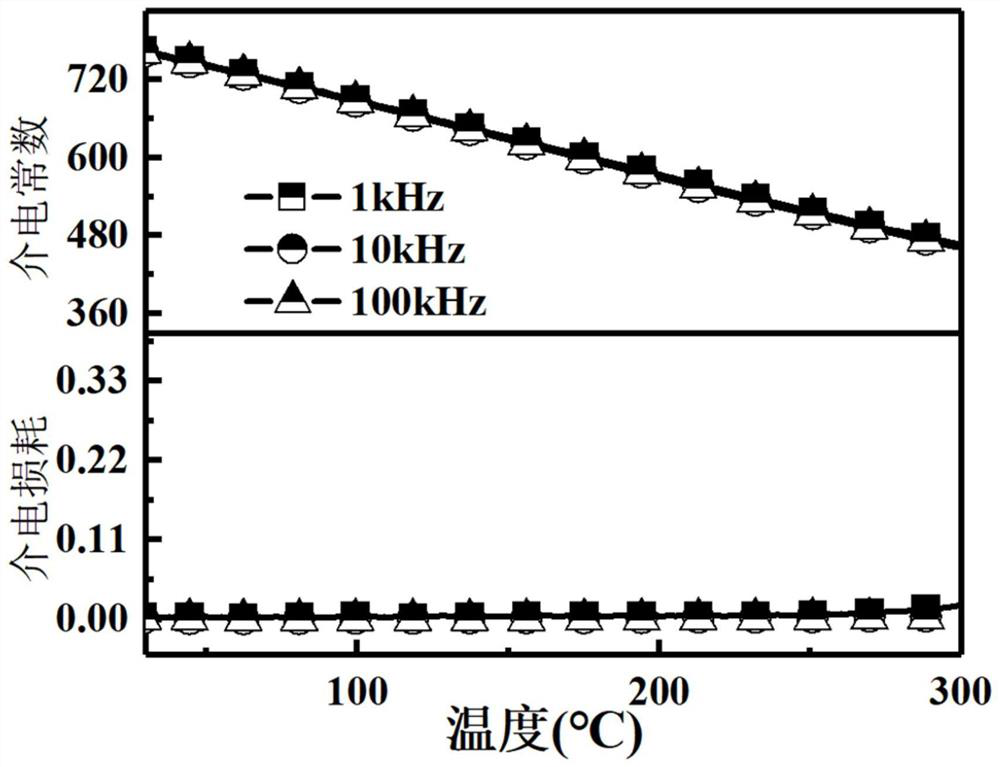

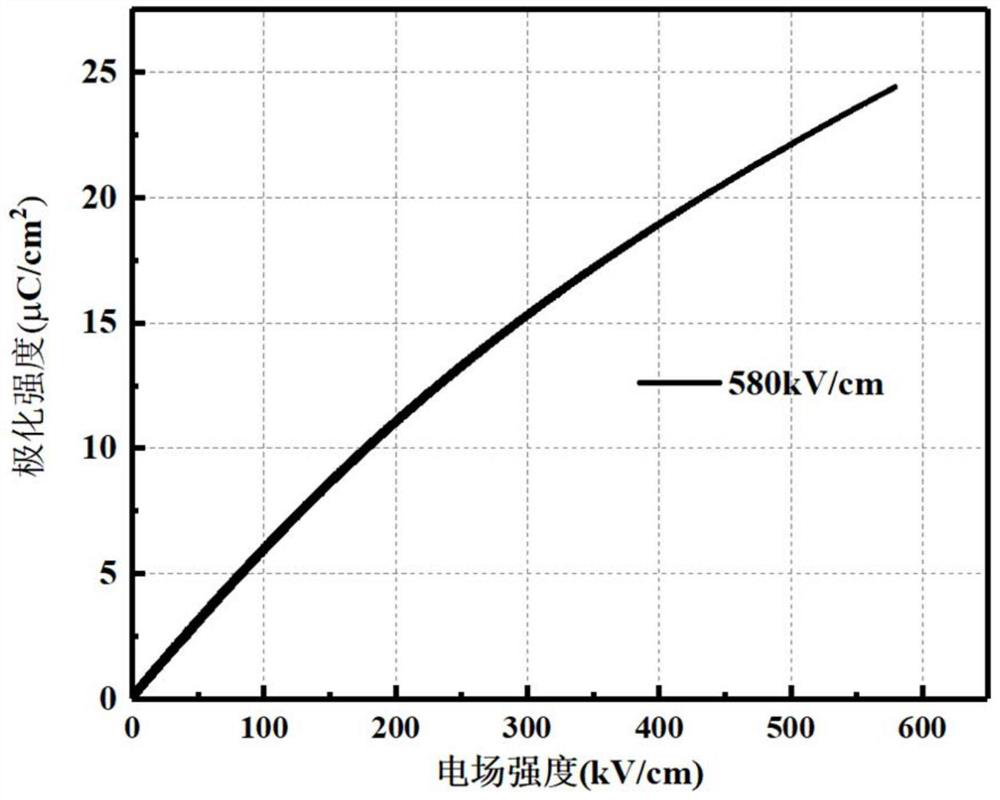

[0038] The chemical composition of strontium bismuth titanate based lead-free ceramics for high-efficiency capacitors is (1-x)Sr 0.7 Bi 0.2 TiO 3 -xBi(Ni 2 / 3 Nb 1 / 3 )O 3 , where x=0, the specific steps are as follows:

[0039] (1) Select Bi with a purity greater than 98% 2 o 3 Powder, SrCO 3 Powder, TiO 2 Powder is the raw material, according to the chemical formula Sr 0.7 Bi 0.2 TiO 3 The raw materials are weighed, and anhydrous ethanol with the same quality as the powder is added, and mixed uniformly through a ball milling process, so that the powder is uniformly mixed to form a slurry. One of the ball mills uses absolute ethanol and ZrO 2 The ball is used as the ball milling medium, the rotating speed is 250r / min, the running direction is adjusted every half hour, and the ball milling time is 12h.

[0040] (2) Bake the above slurry in a constant temperature oven at 90° C., remove absolute ethanol, and grind it in a mortar to obtain a powder;

[0041] (3) Put t...

Embodiment 2

[0047] The chemical composition of strontium bismuth titanate based lead-free ceramics for high-efficiency capacitors is (1-x)Sr 0.7 Bi 0.2 TiO 3 -xBi(Ni 2 / 3 Nb 1 / 3 )O 3 , where x=0.05, the specific steps are as follows:

[0048] (1) Select Bi with a purity greater than 98% 2 o 3 Powder, SrCO 3 Powder, TiO 2 powder, NiO powder and Nb 2 o 5 Powder is the raw material, according to the chemical formula 0.95Sr 0.7 Bi 0.2 TiO 3 -0.05Bi(Ni 2 / 3 Nb 1 / 3 )O 3 The raw materials are weighed, and anhydrous ethanol with the same quality as the powder is added, and mixed uniformly through a ball milling process, so that the powder is uniformly mixed to form a slurry. One of the ball mills uses absolute ethanol and ZrO 2 The ball is used as the ball milling medium, the speed is 290r / min, the running direction is adjusted every half hour, and the ball milling time is 18h.

[0049] (2) Bake the above slurry in a constant temperature oven at 90° C., remove absolute ethanol, an...

Embodiment 3

[0056] The chemical composition of strontium bismuth titanate based lead-free ceramics for high-efficiency capacitors is (1-x)Sr 0.7 Bi 0.2 TiO 3 -xBi(Ni 2 / 3 Nb 1 / 3 )O 3 , where x=0.12, the specific steps are as follows:

[0057] (1) Select Bi with a purity greater than 98% 2 o 3 Powder, SrCO 3 Powder, TiO 2 powder, NiO powder and Nb 2 o 5 Powder is the raw material, according to the chemical formula 0.88Sr 0.7 Bi 0.2 TiO 3 -0.12Bi(Ni 2 / 3 Nb 1 / 3 )O 3 The raw materials are weighed, and anhydrous ethanol with the same quality as the powder is added, and mixed uniformly through a ball milling process, so that the powder is uniformly mixed to form a slurry. One of the ball mills uses absolute ethanol and ZrO 2 The ball is used as the ball milling medium, the rotating speed is 330r / min, the running direction is adjusted every half hour, and the ball milling time is 24h.

[0058] (2) Bake the above slurry in a constant temperature oven at 90° C., remove absolute et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com