Preparation method of high-strength light cellulose-based bionic protective material

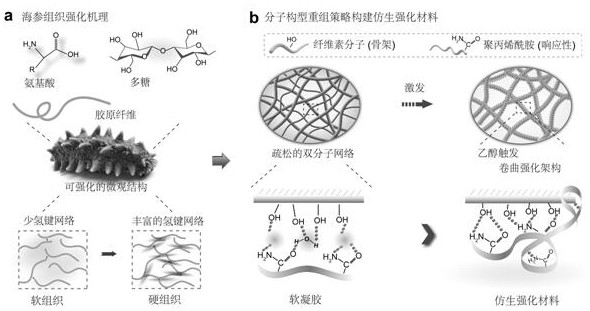

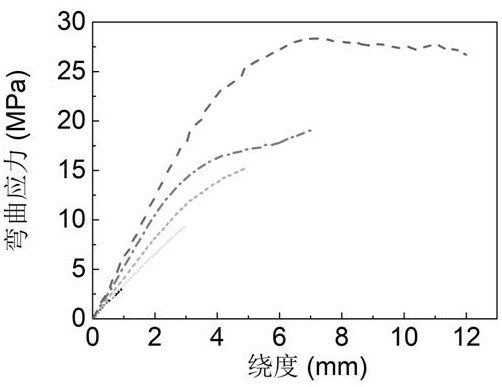

A protective material, cellulose technology, applied in the field of preparation of high-strength lightweight cellulose-based bionic protective materials, can solve the problems of insufficient strength improvement, poor degradation, material damage, etc., to achieve high impact resistance and puncture resistance, high mechanical The effect of performance and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Step 1. Add 1.57g of cellulose (3wt.%) into a three-necked flask containing 50g of [Bmim]Cl ionic liquid, and stir mechanically at 85°C until the cellulose is completely dissolved, and the system becomes a transparent viscous liquid. The time is about for 2h.

[0034] The transparent viscous liquid was evenly placed on the polished silicon wafer carrier by spin coating, and placed in an oven at 85°C for about 12 hours to obtain a uniform and transparent [Bmim]Cl / cellulose system.

[0035] Then put it into distilled water at room temperature, and after the water molecules completely replace the [Bmim]Cl ionic liquid (about 60 min), a uniform transparent hydrogel is formed.

[0036] Step 2, preparation of polymer aqueous solution

[0037] Weigh 20 g of acrylamide, add it to 150 g of deionized water, stir with a magnetic stirrer at room temperature for 30 min, then add 0.1 g of ammonium persulfate and 0.02 g of N - N' methylenebisacrylamide, and continue stirring 20 min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com