Melamine foam reinforced silicon dioxide aerogel composite material and application thereof

A technology of silica and composite materials, applied in the direction of silicon compounds, inorganic chemistry, electrical components, etc., can solve the problems of large volume, achieve the effect of small density, uniform gap size, and inhibit the growth of coagulated particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

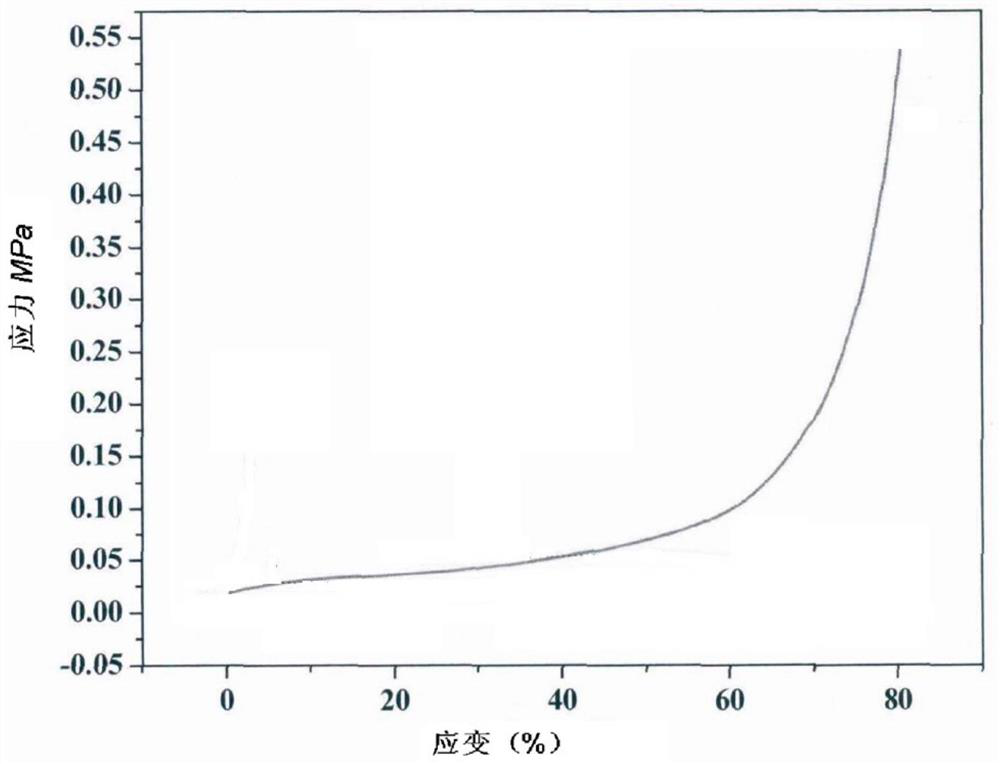

[0037] The present embodiment provides a kind of melamine foam reinforced silica airgel composite material, is to be 93% SiO by weight percentage 2 Airgel and 7% melamine foam are made, and the preparation method specifically includes the following steps:

[0038] (1) Take methyltrimethoxysilane, sodium citrate, absolute ethanol and deionized water, add hydrochloric acid alcohol solution, adjust the pH value of the solution to 2.5, stir vigorously at room temperature and carry out hydrolysis reaction for 5 hours to obtain a silica sol system; The molar ratio of methyltrimethoxysilane, sodium citrate, absolute ethanol and deionized water is 1:0.8:15:10:0.010;

[0039] (2) Add mannitol into the silica sol system, stir evenly, then add ammonia water alcohol solution to adjust the pH to 8.0, stir to make the solution fully mixed, stop stirring after 5 minutes, pour into a mold with melamine foam, and immerse in melamine Foam, under airtight conditions at 50°C, aged for 30 hours t...

Embodiment 6

[0072] This embodiment provides that this embodiment provides a melamine foam reinforced silica airgel composite material, which is made of 93% SiO by weight percentage 2 Airgel and 7% melamine foam are made, and the preparation method of this embodiment is the same as that of Example 1 except that sodium citrate is not added in step (1).

[0073] Performance test result (test method is identical with embodiment 1): specific surface area 453.9m 2 / g, porosity 89.6%, density 9.9mg / cm 3 , The thermal conductivity is 22.35mw / mk, and the compressive strength is about 0.36MPa (25% deformation).

Embodiment 7

[0075] The present embodiment provides a kind of melamine foam reinforced silica airgel composite material, is to be 93% SiO by weight percentage 2 Airgel and 7% melamine foam, the preparation method of this example is the same as Example 1 except that no propylene glycol is added in step (2).

[0076] Performance test result (test method is identical with embodiment 1): specific surface area 455.1m 2 / g, porosity 90.1%, density 9.8mg / cm 3 , The thermal conductivity is 22.21mw / mk, and the compressive strength is about 0.37MPa (25% deformation).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com