rH-PLGA/PEI microsphere and dopamine modified small-caliber intravascular stent material and preparation method thereof

A vascular stent, dopamine technology, applied in pharmaceutical formulations, microcapsules, transportation and packaging, etc., can solve problems such as inability to provide anticoagulant properties, and achieve the goal of promoting vascular endothelial cell adhesion, promoting anticoagulant properties, and accelerating speed and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

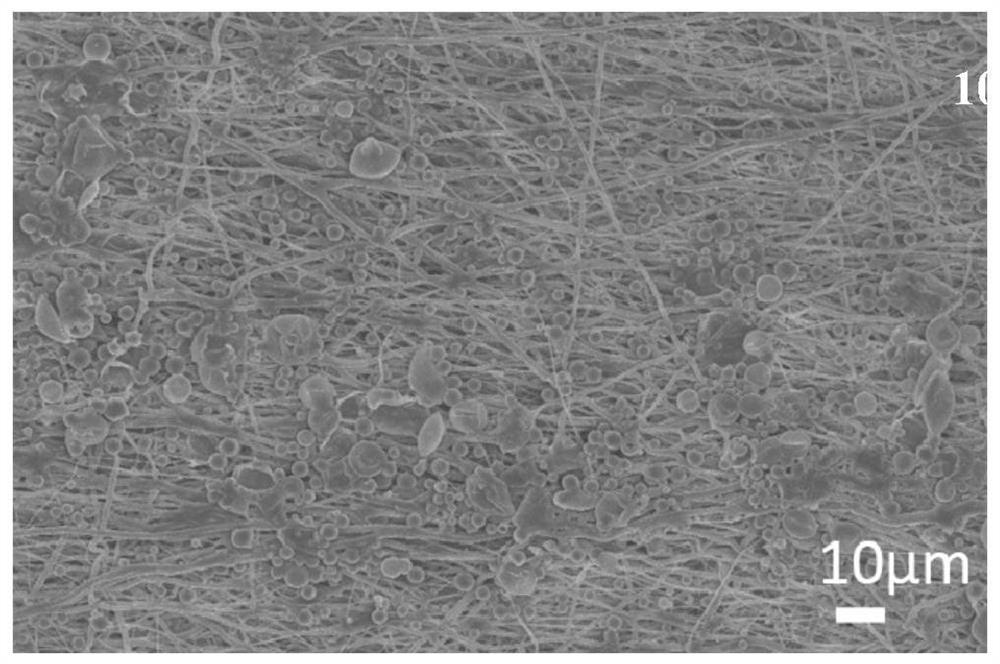

[0045] Step 1: Preparation of PCL nanofiber scaffold

[0046] Add polycaprolactone to hexafluoroisopropanol, PCL / hexafluoroisopropanol=1.5g / 15ml, stir for 12 hours to make a spinning solution, and use electrospinning technology to prepare a PCL nanofiber support; wherein, the spinneret The distance from the receiving iron plate is adjusted to 18cm; the flow rate of the spinning solution in the syringe pump is 2ml / h, and the liquid volume is adjusted to 8ml; the rotation speed of the rotating motor is adjusted to 100 rpm; It is 11kv; turn on the power of the rotating motor, turn on the switch of the injection pump, and the nanofiber bundle will be ejected from the spinning needle. After the spinning is stable, the continuous spinning time will be 240 minutes. After the spinning is completed, turn off the switch of the syringe pump and the motor in turn. Power supply, obtain PCL nanofiber support;

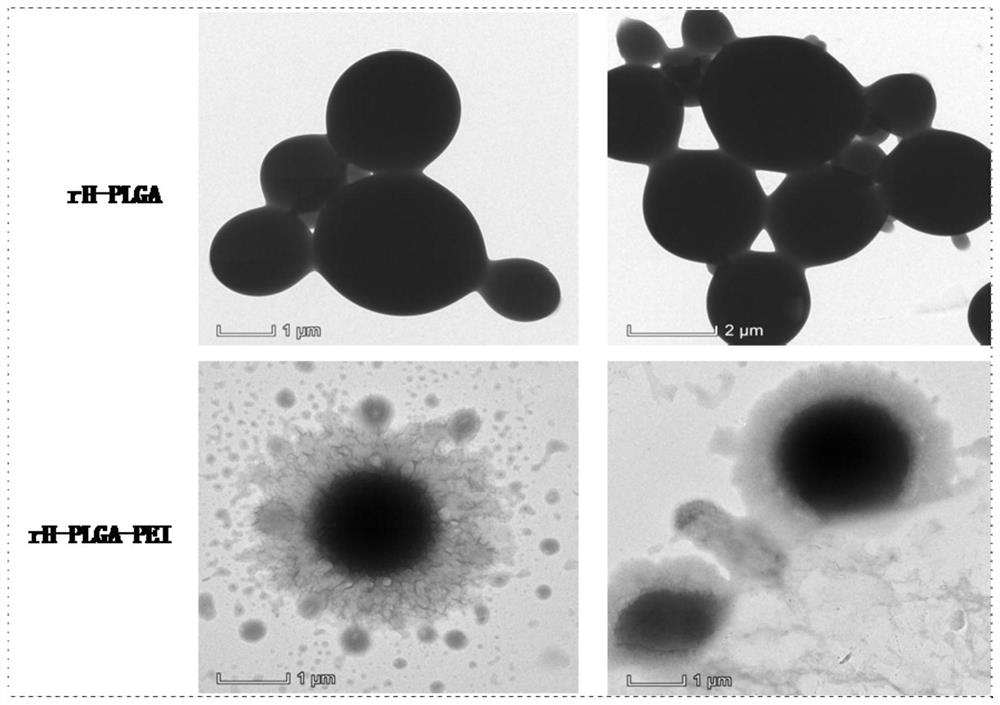

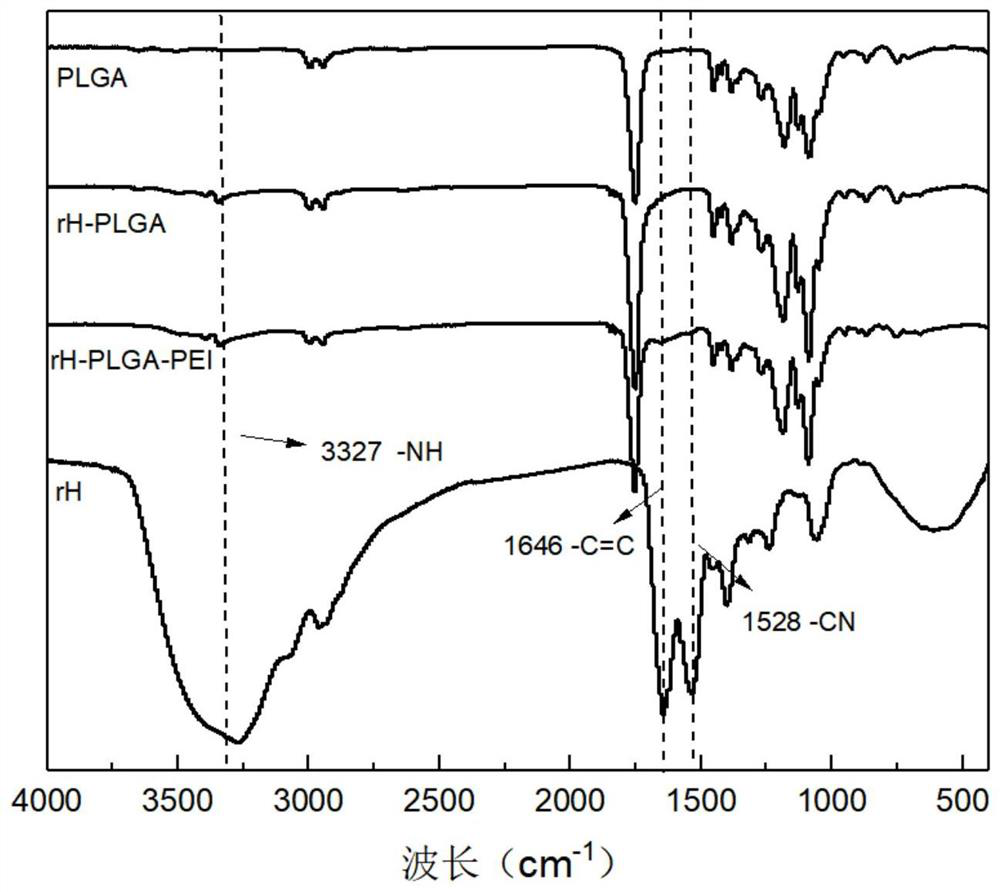

[0047] Step 2: Preparation of rH-PLGA-PEI microspheres

[0048] Water-in-oil-i...

Embodiment 2

[0054] Step 1: Preparation of PCL nanofiber scaffold

[0055] Add polycaprolactone in hexafluoroisopropanol, PCL / hexafluoroisopropanol=2g / 15ml, stir for 24h to make spinning solution, and use electrospinning technology to prepare PCL nanofiber support; wherein, the spinneret and The distance to accept the iron plate is adjusted to 18cm; the flow rate of the spinning liquid in the syringe pump is 2ml / h, and the liquid volume is adjusted to 8ml; the rotating speed of the rotating motor is adjusted to 100 rpm. After the power is turned on, the voltage of the high-voltage direct current generator is adjusted to 11kv; after turning on the power supply of the rotating motor and turning on the switch of the injection pump, the nanofiber bundles are ejected from the spinning needle. After the spinning is stable, the continuous spinning time is 240 minutes. After the filament is finished, turn off the syringe pump switch and the motor power supply in turn to obtain the PCL nanofiber sc...

Embodiment 3

[0064] Test of anticoagulant performance of rH-PLGA / PEI microspheres and dopamine-modified small-caliber vascular stent materials. Film samples (1.0×1.0cm 2 ) was placed in a cuvette, and 0.1 mL of plasma (PPP) was incubated at 37°C for 30 minutes. Then, the plasma coagulation time (ie APTT value) was recorded by an automatic coagulation analyzer, and the test was repeated three times to obtain the average value. No sample film was added to the blank control group, and other operating conditions and operating methods were exactly the same as those of the experimental group. APTT results such as Figure 4 As shown, the results show that the APTT of rH-PLGA / PEI microspheres and dopamine-modified small-caliber vascular scaffolds is 8.8s longer than that of blank PCL, indicating that the loading of rH-PLGA / PEI microspheres significantly improves the anticoagulant properties of PCL . Figure 4 PPP in the abscissa means blank control group, PCL means PCL nanofiber scaffold, PDA-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com