Flexible circuit board and manufacturing method thereof

A technology of flexible circuit boards and manufacturing methods, which is applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve problems such as large elastic modulus, FPC cannot be applied, and the number of times of bending resistance cannot exceed 100,000 times. The effect of good pattern quality and high bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

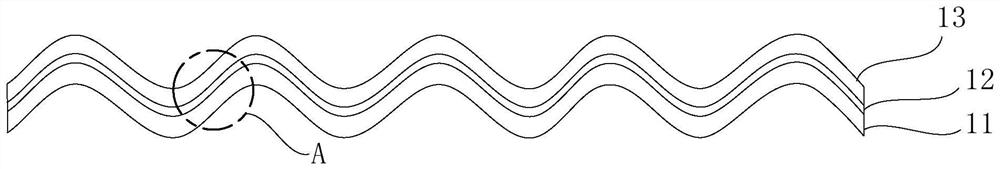

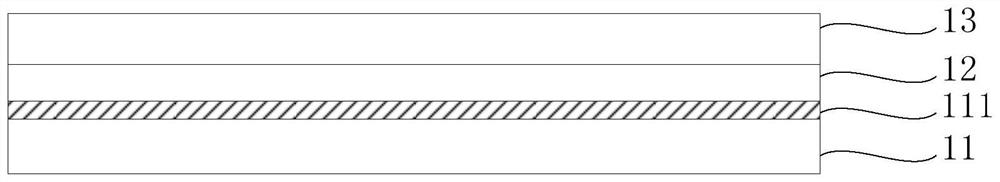

[0042] figure 1 is a sectional view of the flexible circuit board shown according to the first embodiment. Such as figure 1 As shown, the flexible circuit board of this embodiment includes a dielectric elastic substrate 11 and a conductive pattern layer 12 , the dielectric elastic substrate 11 is corrugated, and the conductive pattern layer 12 is located on one side of the dielectric elastic substrate 11 .

[0043] The dielectric elastic substrate 11 is a dielectric material with suitable elasticity such as polydimethylsiloxane (PDMS), polyurethane (TPU), and the conductive pattern layer 12 is preferably copper. Optionally, the dielectric elastic substrate 11 The thickness is 25 μm˜1 mm, and the thickness of the conductive pattern layer 12 is 1 μm˜16 μm. The conductive pattern layer 12 is located on one side of the dielectric elastic substrate 11, and the dielectric elastic substrate 11 is wavy, so that the flexible circuit board as a whole is wavy, and the amplitude and per...

no. 2 example

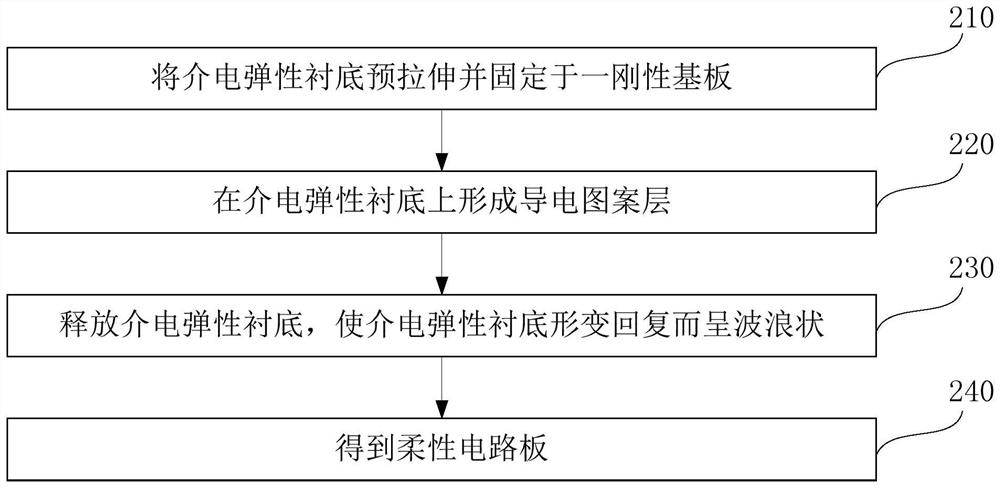

[0052] image 3 It is a schematic flowchart of the manufacturing method of the flexible circuit board according to the second embodiment. Such as image 3 As shown, the manufacturing method of the flexible circuit board of this embodiment includes the following steps:

[0053] In step 210, the dielectric elastic substrate is pre-stretched and fixed to a rigid substrate.

[0054] Wherein, the dielectric elastic substrate is a dielectric material with suitable elasticity such as polydimethylsiloxane (PDMS) and polyurethane (TPU). Optionally, the thickness of the dielectric elastic substrate is 25 μm to 1 mm. The pre-stretching stretch rate of the elastic substrate depends on the stretch rate of the flexible circuit board to be designed, such as 20%, 30% and so on. After the dielectric elastic substrate is pre-stretched, the stretched two ends can be bent and wound to the back of the rigid substrate, and pasted and fixed by high-viscosity and high-temperature-resistant adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com