Preparation method and application of hafnium nitride film with high crystal quality

A thin film preparation, hafnium nitride technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of slow growth rate of ALD material, low heating temperature of substrate, no test results, etc. Achieve the effect that is beneficial to the preparation of low stress and high crystalline quality, the improvement of film density and surface flatness, and the high film deposition growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

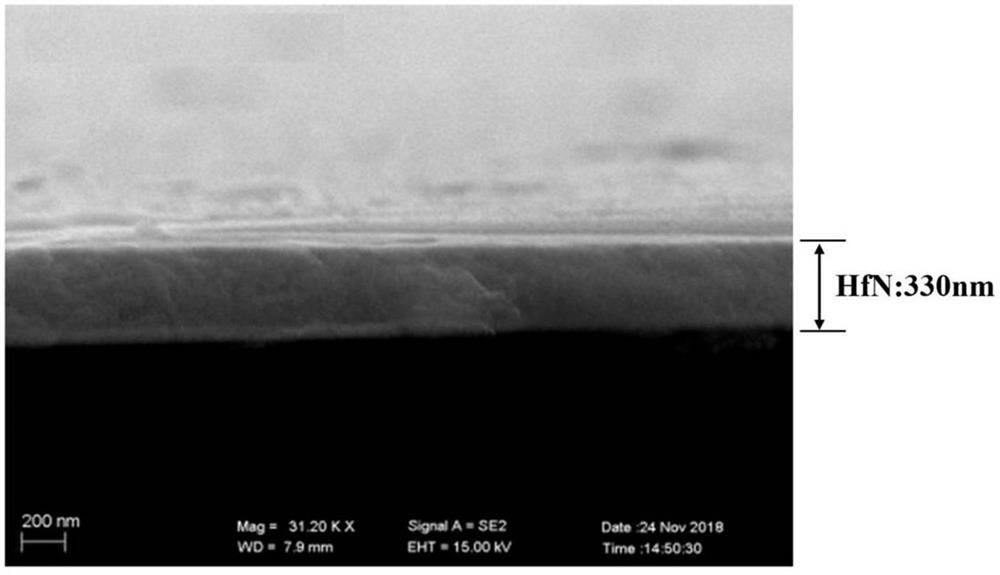

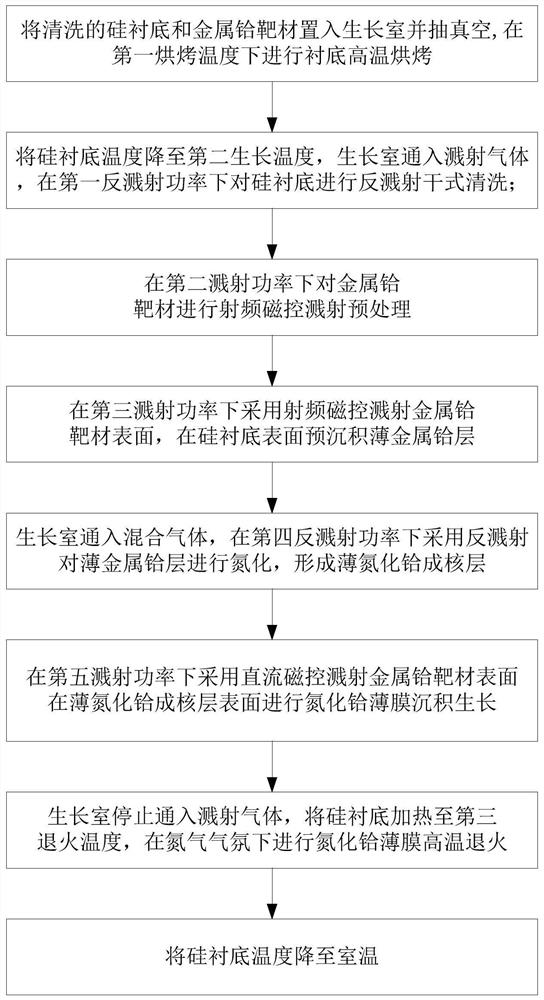

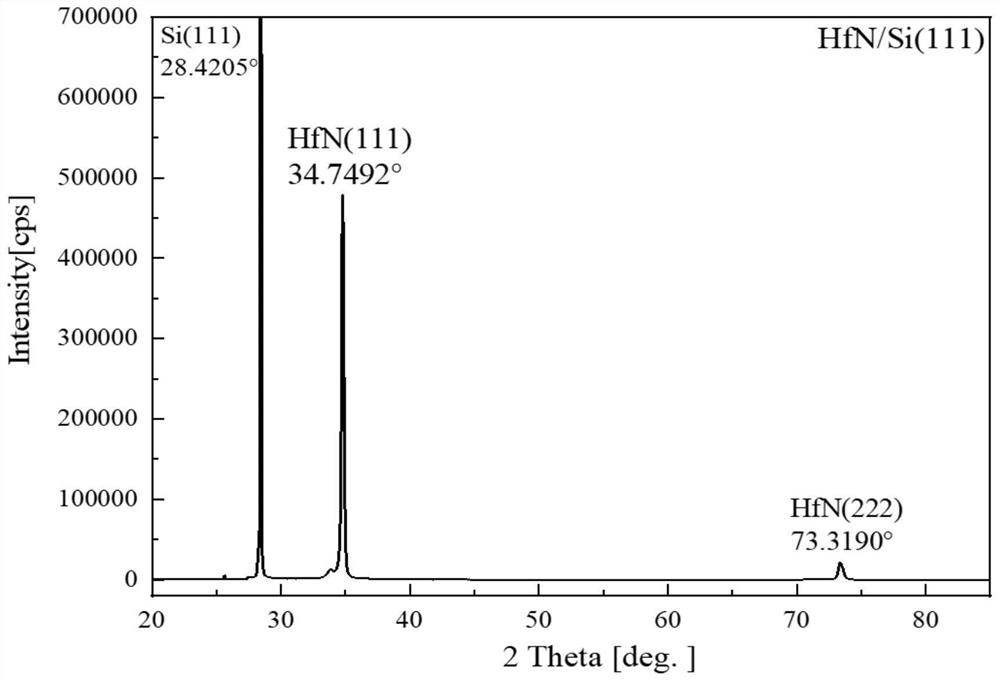

[0037] The invention discloses a method for preparing a hafnium nitride thin film with high crystal quality, such as figure 1 shown, including:

[0038] S1. Put the cleaned silicon substrate and metal hafnium target into the growth chamber of the magnetron sputtering equipment and evacuate to ultra-high vacuum, heat the silicon substrate to the first baking temperature, and perform ultra-high vacuum on the silicon substrate Baking under high temperature conditions;

[0039]The silicon substrate is a silicon single crystal substrate whose crystal orientation is not limited to (111), (100), (110) and (113), the size is not less than 1 inch in diameter, and the purity of the metal hafnium target is not less than 99.99%. In this embodiment, a 2-inch Si(111) substrate and a metal hafnium target with a diameter of 83 mm and a purity of 99.99% are used. The distance between the silicon substrate and the metal hafnium target is 5 to 15 cm. In this embodiment, the distance between th...

Embodiment 2

[0054] Embodiment 2 is the same as the method for preparing hafnium nitride thin film in embodiment 1, the difference is:

[0055] In step S1, the distance between the silicon substrate and the metal hafnium target is 5 cm; at the first baking temperature of 700° C., the silicon substrate is subjected to ultra-high vacuum and high-temperature baking surface treatment for 40 minutes to remove the particles adsorbed on the surface of the silicon substrate. Gas and residual impurities and oxide layer;

[0056] In step S2, the second growth temperature is 350°C, and the rotation speed of the substrate tray for the substrate rotation is 120 revolutions per minute; the low-energy argon ions generated by the sputtering gas argon ignition discharge are used for the first reverse sputtering power of 200W. Reverse sputtering dry cleaning on the surface of the silicon substrate for 3 minutes to completely remove the remaining impurities and oxide layer on the surface of the silicon subst...

Embodiment 3

[0064] Embodiment 3 is the same as the method for preparing hafnium nitride thin film in embodiment 1, the difference is:

[0065] In step S1, the distance between the silicon substrate and the metal hafnium target is 15 cm; at the first baking temperature of 850° C., carry out ultra-high vacuum high-temperature baking surface treatment of the silicon substrate for 15 minutes to remove the adsorbed particles on the surface of the silicon substrate. Gas and residual impurities and oxide layer;

[0066] In step S2, the second growth temperature is 650°C, and the rotation speed of the substrate tray on which the substrate rotates is 5 revolutions per minute; the low-energy argon ions generated by the sputtering gas argon initiation discharge are used at the first reverse sputtering power of 100W. Reverse sputtering dry cleaning on the surface of the silicon substrate for 20 minutes to completely remove the remaining impurities and oxide layer on the surface of the silicon substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com