Sodium potassium aluminosilicate/collagen composite material as well as preparation method and application thereof

A technology of potassium sodium aluminosilicate and composite material, which is applied in the field of leather making, can solve the problems of different sources of inorganic fillers and different components, and achieve the effects of good filling effect, similar hand feeling and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

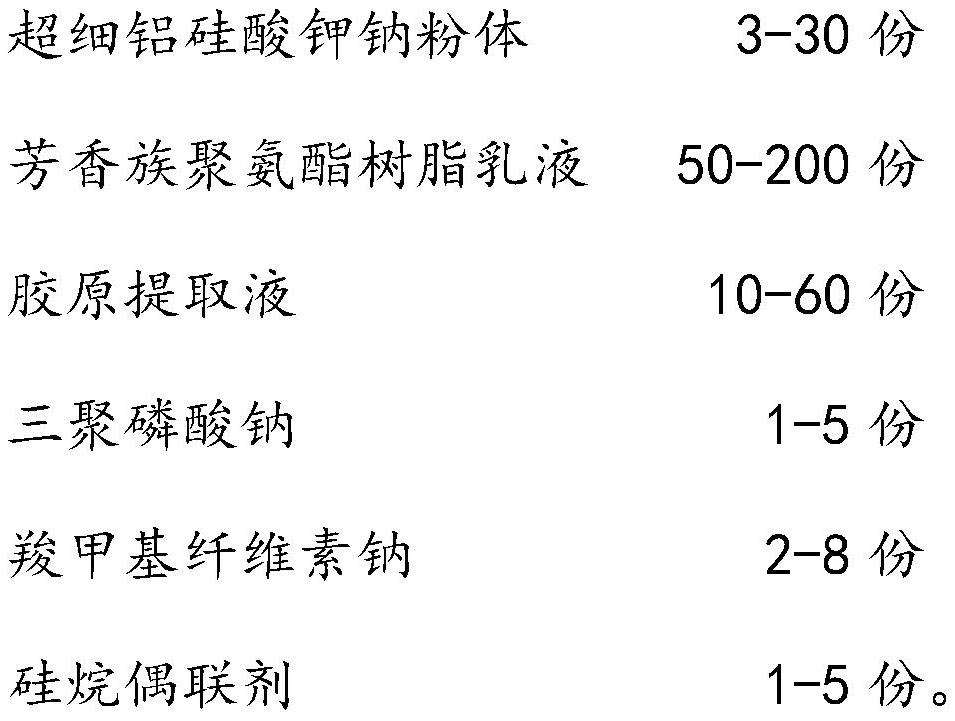

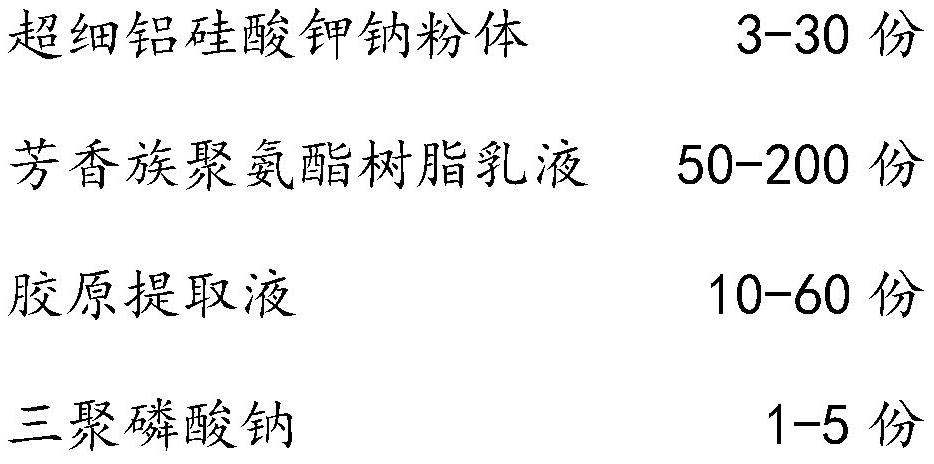

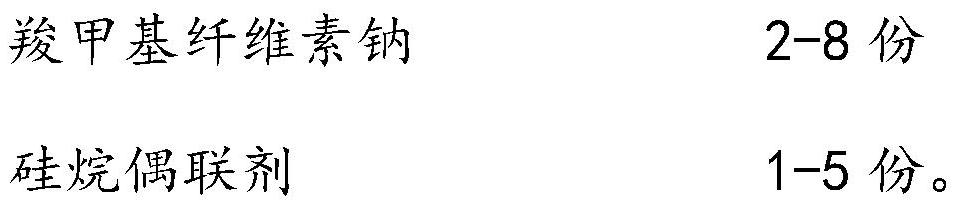

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of sodium potassium aluminosilicate / collagen composite material, comprising the steps of:

[0029] Step 1: ultrasonically disperse 5 parts of nano-silica powder and 5 parts of alumina powder in 1000 parts of deionized water to obtain a silica / alumina dispersion, and then dissolve 15 parts of potassium nitrate, Mix 10 parts of sodium nitrate evenly, add 10 parts of polyethylene glycol, 50 parts of ammonia water and 50 parts of citric acid, control the reaction temperature at 70°C, and react for 6 hours to prepare sodium potassium aluminosilicate hydrogel.

[0030] Step 2: Burn the potassium sodium aluminosilicate hydrogel at 130°C for 1.5h to obtain the carbon layer-wrapped potassium sodium aluminosilicate powder, grind the carbon layer-wrapped potassium sodium aluminosilicate powder and then heat it at 900 Burn at ℃ for 8 hours to obtain sodium potassium aluminosilicate powder, and ball mill the sodium potassium aluminosilicate powder to obtain ultr...

Embodiment 2

[0034] A preparation method of sodium potassium aluminosilicate / collagen composite material, comprising the steps of:

[0035] Step 1: ultrasonically disperse 1 part of nano-silica powder and 1 part of alumina powder in 1000 parts of deionized water to obtain a silica / alumina dispersion, and then dissolve 5 parts of potassium nitrate, Mix 5 parts of sodium nitrate evenly, add 5 parts of polyethylene glycol, 20 parts of ammonia water and 20 parts of citric acid, control the reaction temperature at 80°C, and react for 9 hours to prepare sodium potassium aluminosilicate hydrogel.

[0036] Step 2: Burn the potassium sodium aluminosilicate hydrogel at 100°C for 3 hours to prepare the carbon layer-wrapped potassium sodium aluminosilicate powder, grind the carbon layer-wrapped potassium sodium aluminosilicate powder and then heat it at 800°C Burn for 12 hours to obtain potassium sodium aluminosilicate powder, and ball mill the potassium sodium aluminosilicate powder to obtain ultrafi...

Embodiment 3

[0040] A preparation method of sodium potassium aluminosilicate / collagen composite material, comprising the steps of:

[0041]Step 1: ultrasonically disperse 10 parts of nano-silica powder and 10 parts of alumina powder in 1000 parts of deionized water to obtain a silica / alumina dispersion, and then dissolve 25 parts of potassium nitrate, After mixing 25 parts of sodium nitrate evenly, add 50 parts of polyethylene glycol, 100 parts of ammonia water and 100 parts of citric acid, control the reaction temperature at 80°C, and react for 9 hours to prepare sodium potassium aluminosilicate hydrogel.

[0042] Step 2: Burn the potassium sodium aluminosilicate hydrogel at 300°C for 1 hour to prepare the carbon layer-wrapped potassium sodium aluminosilicate powder, grind the carbon layer-wrapped potassium sodium aluminosilicate powder and then heat it at 1000°C Burn for 3 hours to obtain potassium sodium aluminosilicate powder, and ball mill the potassium sodium aluminosilicate powder t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com