Welding method for swirl vanes of cement burner

A technology of swirling blades and welding methods, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., and can solve problems such as difficult control of welding precision, weld fatigue cracks, and swirl wind angle deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

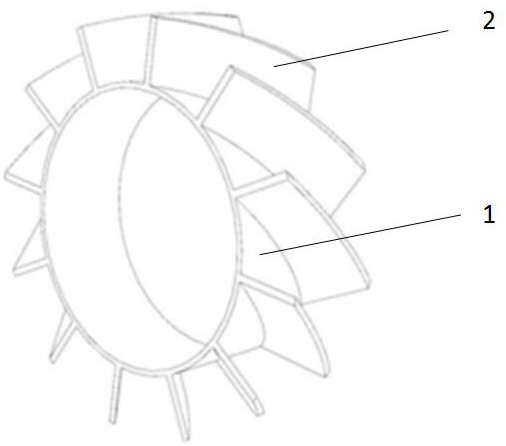

[0023] The present invention as figure 1 As shown, in the work, the inner air duct 1 is made of incoloy800, and the swirl blade 2 is made of cobalt 50 (that is, umco-50 alloy), including the following welding steps:

[0024] Pretreatment (that is, before welding), the surface to be welded of the swirl blade and the inner air duct is polished with 400#, 600#, and 800# sandpaper in sequence to improve the grinding effect and effectively remove impurities such as oxides; ultrasonic cleaning in acetone for 15 -30min, remove the oil on the surface of the sample to be welded;

[0025] Plating a nickel layer on the surface to be welded of the pretreated swirl blade with a thickness of 3-5um; then thermally spraying Ni-based high-temperature solder onto the surface of the nickel layer;

[0026] Fix the treated swirl blades and inner air pipes with relevant fixtures, and put them into a vacuum brazing furnace for brazing. Heat to 600°C at a speed of 10-15°C / min, keep warm for 20-30mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com