Method for preparing silicon carbide/titanium carbide composite ceramics

A technology of multiphase ceramics and titanium carbide is applied in the field of preparation of silicon carbide/titanium carbide multiphase ceramics. , the effect of controllable titanium content and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Under the protection of an inert atmosphere, dissolve titanocene dichloride with dimethylformamide, stir, then add hyperbranched polycarbosilane, the quality of titanocene dichloride, hyperbranched polycarbosilane and dimethylformamide The ratio is 1:1:15;

[0020] 2) The mixture obtained in step 1) is distilled under reduced pressure to remove the solvent;

[0021] 3) The mixture obtained in step 2) was cracked at 1400° C. for 120 minutes under an inert atmosphere to prepare silicon carbide / titanium carbide composite ceramics.

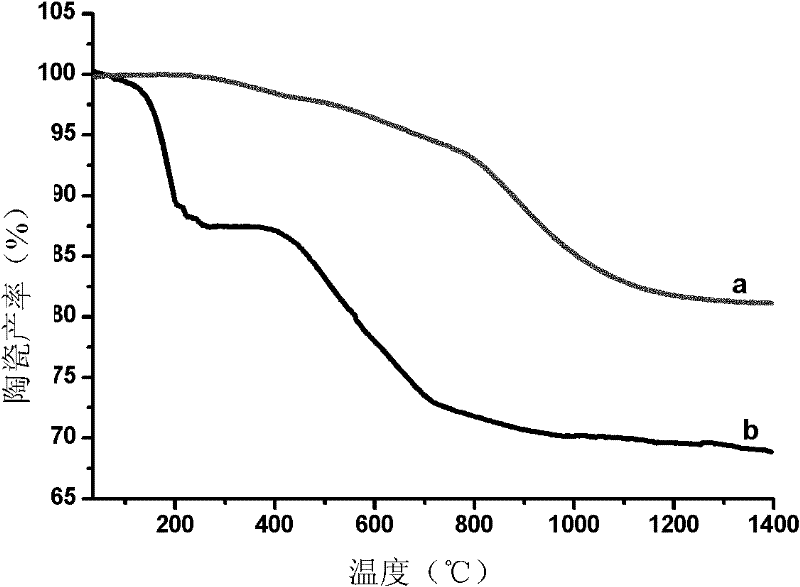

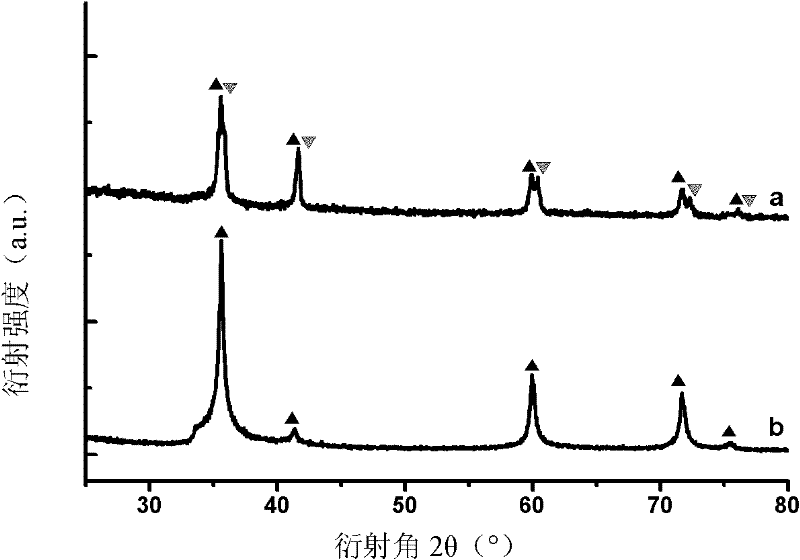

[0022] The average structural formula of hyperbranched polycarbosilane is -[SiH 1.7 (CH 3 ) 0.2 (CH 2 CH=CH 2 ) 0.1 -CH 2 ] n -, determined by thermogravimetric analysis (TGA) (see figure 1 ), the ceramic yield of the hyperbranched polycarbosilane / dichlorotitanocene hybrid precursor at 1400°C was 81.1%, while the ceramic yield of the raw material hyperbranched polycarbosilane at 1400°C was 68.9%; the silicon carbide thus prepared / ...

Embodiment 2

[0024] 1) Under the protection of an inert atmosphere, dissolve titanocene dichloride with tetrahydrofuran, stir, then add hyperbranched polycarbosilane, the mass ratio of titanocene dichloride, hyperbranched polycarbosilane and tetrahydrofuran is 1:3.3:65;

[0025] 2) The mixture obtained in step 1) is distilled under reduced pressure to remove the solvent;

[0026] 3) The mixture obtained in step 2) was cracked at 1300° C. for 10 minutes under an inert atmosphere to prepare silicon carbide / titanium carbide composite ceramics.

[0027] The average structural formula of the raw material hyperbranched polycarbosilane used is-[SiH 1.5 (CH 3 ) 0.5 -CH 2 ] n -, as determined by thermogravimetric analysis (TGA), the ceramic yield of the hyperbranched polycarbosilane / dichlorotitanocene hybrid precursor at 1300°C was 76.4%, while the ceramic yield of the raw material hyperbranched polycarbosilane at 1300°C is 67.5%; the chemical composition of the silicon carbide / titanium carbid...

Embodiment 3

[0029] 1) Under the protection of an inert atmosphere, dissolve titanocene dichloride with chloroform, stir, then add hyperbranched polycarbosilane, the mass ratio of titanocene dichloride, hyperbranched polycarbosilane and chloroform is 1: 2:30.

[0030] 2) The mixture obtained in step 1) is distilled off under reduced pressure in vacuo to remove the solvent.

[0031] 3) The mixture obtained in step 2) was cracked at 1400° C. for 30 minutes under an inert atmosphere to prepare silicon carbide / titanium carbide composite ceramics.

[0032] The average structural formula of the raw material hyperbranched polycarbosilane used is-[SiH 1.5 (CH 3 ) 0.3 (C≡CH) 0.2 -CH 2 ] n -, as determined by thermogravimetric analysis (TGA), the ceramic yield of the hyperbranched polycarbosilane / dichlorotitanocene hybrid precursor at 1400°C was 82.1%, while the ceramic yield of the raw material hyperbranched polycarbosilane at 1400°C is 72.9%; the chemical composition of the silicon carbide / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com