Magnetic core-shell mesoporous surface molecular imprinting composite nano material and preparation method thereof

A technology of surface molecular imprinting and composite nanomaterials, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve problems such as difficult magnetic separation, weakened magnetic properties, and slow adsorption equilibrium speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

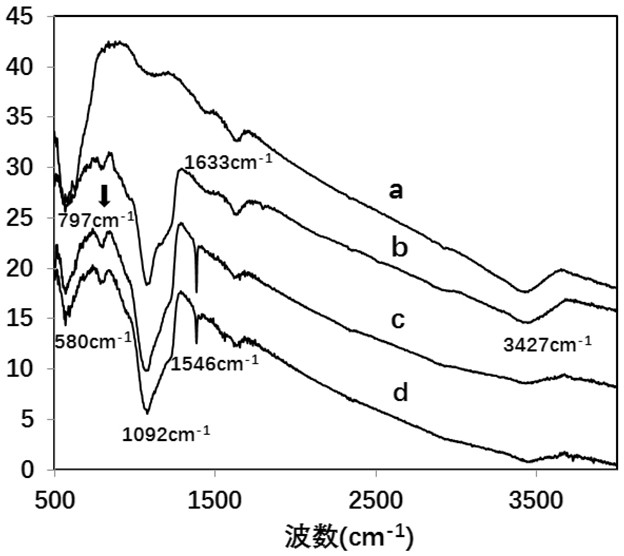

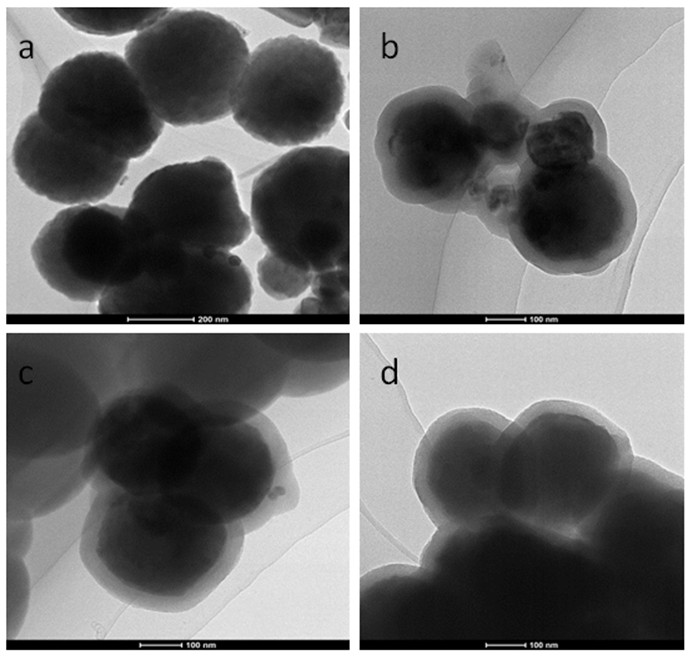

[0049] The preparation steps of a magnetic core-shell mesoporous surface molecularly imprinted composite nanomaterial are as follows:

[0050] (1) Synthesis of Fe 3 o 4 magnetic nanoparticles

[0051] 0.5 g Fe 3 o 4 , 150 mL of absolute ethanol, and 150 mL of deionized water were added to a 500 mL three-necked flask, and ultrasonically dispersed for 10 min; 0.6 g of resorcinol and 4.8 mL of concentrated ammonia water with a mass concentration of 28% were added, and stirred at 30°C for 1 h; Add 0.8 mL of formaldehyde with a mass concentration of 37% and 1.4 mL of TEOS dropwise, stir at 30 °C for 6 h, then stir at 80 °C for 10 h, wash the product three times with deionized water and ethanol, and dry in a 60 °C oven 10 h, get Fe 3 o 4 magnetic nanoparticles.

[0052] (2) Preparation of magnetic core-shell mesoporous nanocomposite particles

[0053] Magnetic core-shell mesoporous nanocomposite particles were synthesized by the improved Stöber method, and 1.0 g Fe 3 o 4 M...

Embodiment 2

[0068] The preparation steps of a magnetic core-shell mesoporous surface molecularly imprinted composite nanomaterial are as follows:

[0069] (1) Synthesis of Fe3O4 magnetic nanoparticles, same as in Example 1.

[0070] (2) Preparation of magnetic core-shell mesoporous nanocomposite particles, same as in Example 1.

[0071] (3) Preparation of amino-modified magnetic core-shell mesoporous nanocomposite particles

[0072] Add 1.2 g of magnetic core-shell mesoporous nanocomposite particles prepared in step (2) and 60 mL of toluene into a three-neck flask, disperse uniformly by ultrasonic for 5 min, and slowly add 5 mL of 3-(2-aminoethyl)-aminopropyl Trimethoxysilane (TSD), reflux reaction at 85°C for 4 h, so that the silane reagent can be adsorbed onto SiO 2 In the mesoporous channel, cooled to room temperature, separated by magnet, and washed twice with toluene and deionized water successively to remove unreacted or unadsorbed SiO 2 The silane reagent in the mesoporous chann...

Embodiment 3

[0077] The application of the magnetic core-shell mesoporous surface molecularly imprinted composite nanomaterial of the present invention as a magnetic solid-phase extraction agent for adsorbing phthalates has excellent specific adsorption performance and high adsorption capacity (saturation) for six PAEs The adsorption capacity is 523.9 mg / g), the adsorption kinetics is fast, and the adsorption equilibrium is reached in 5 minutes. The material can be reused. It is an ideal magnetic solid-phase extraction material for the extraction and purification of phthalates.

[0078] In order to evaluate the selective adsorption performance of the material of the present invention, two analogues, butyl benzoate (BB) and dodecylbenzene (DB), which are similar in structure to PAEs, were selected to compare the adsorption capacity. Adsorption performance comparison. Accurately weigh 10 mg of the product of the present invention or non-molecularly imprinted composite (Fe 3 o 4 @SiO 2 @mS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com