Method for producing oyster mushroom sticks by adopting granular strains and special equipment thereof

A technology of granular and oyster mushrooms, which is applied in the fields of botanical equipment and methods, applications, mushroom cultivation, etc., can solve the problems of increased pollution rate, long production cycle, and unsuitable inoculation of granular strains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

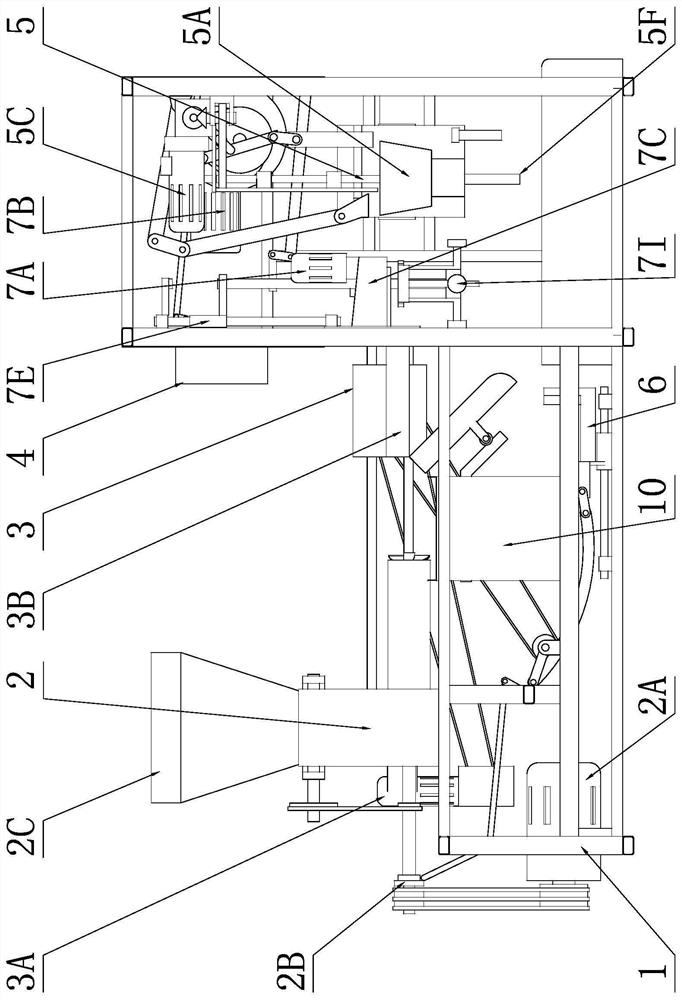

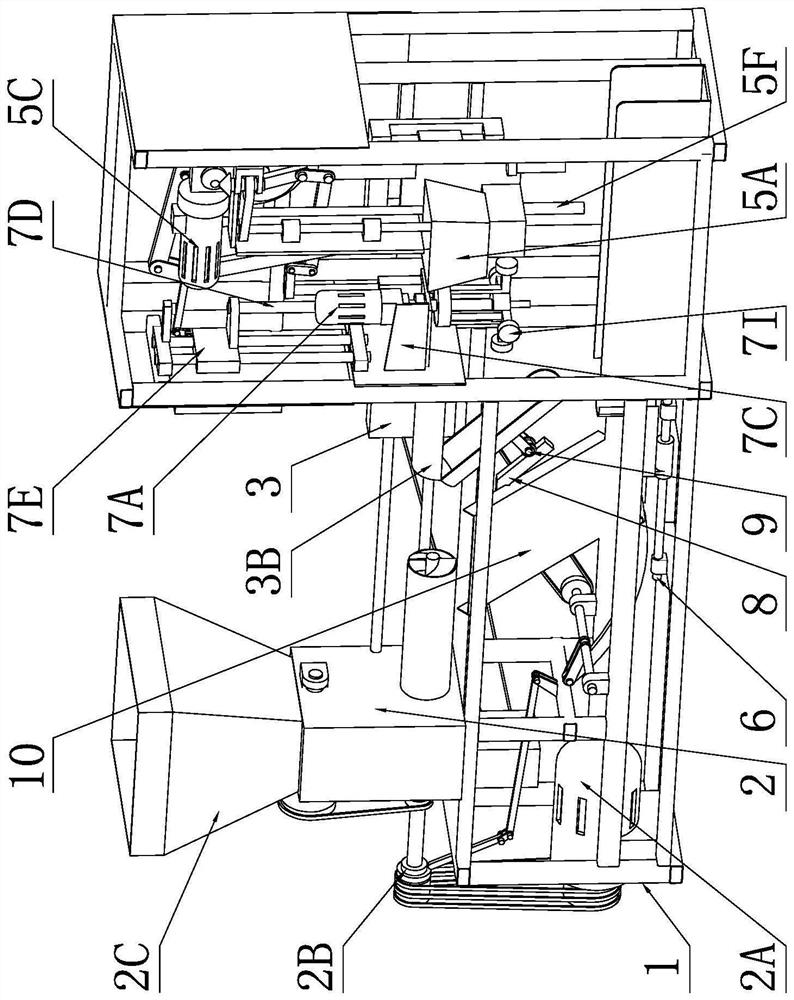

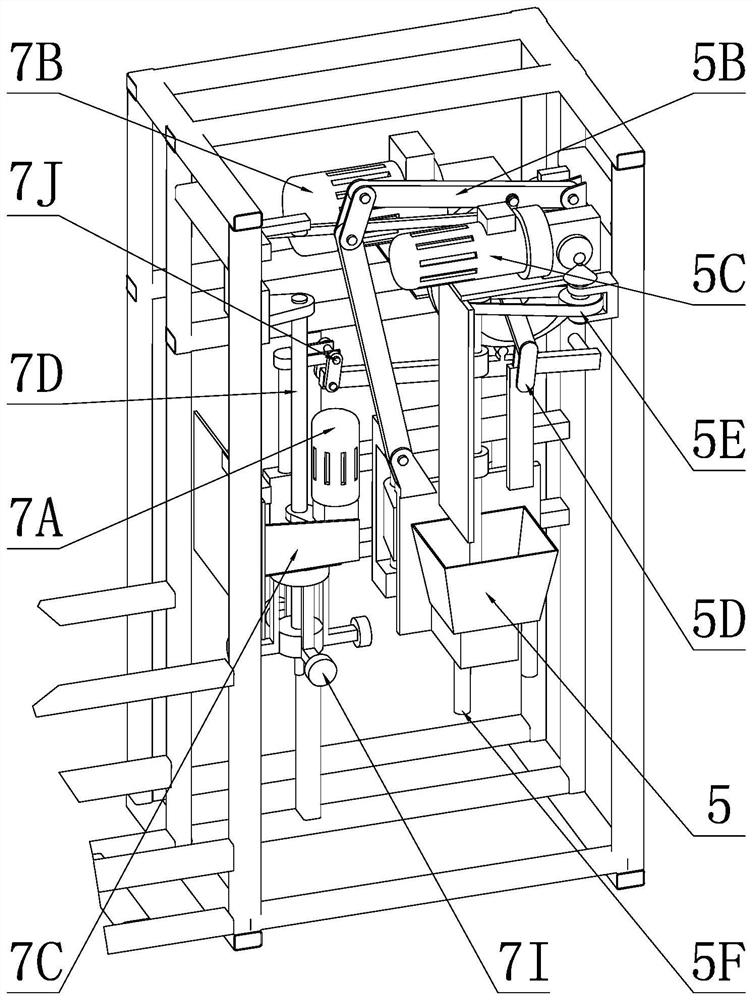

[0098] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but they are not intended to limit the present invention. The scope of protection of the present invention is subject to the content recorded in the claims, and any replacement of equivalent technical means based on the specification does not depart from the scope of protection of the present invention.

[0099] The method for producing Pleurotus ostreatus bacterium sticks by adopting granular strains comprises the following process steps:

[0100] A. Mixing

[0101] The components used to prepare the oyster mushroom culture material are mixed evenly in proportion to make the oyster mushroom culture material raw material, and the oyster mushroom culture material raw material is placed in a fermentation device, and the fermentation device is composed of more than two air It is composed of a closed fermentation device connected by road;

[0102] B. Ferment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com