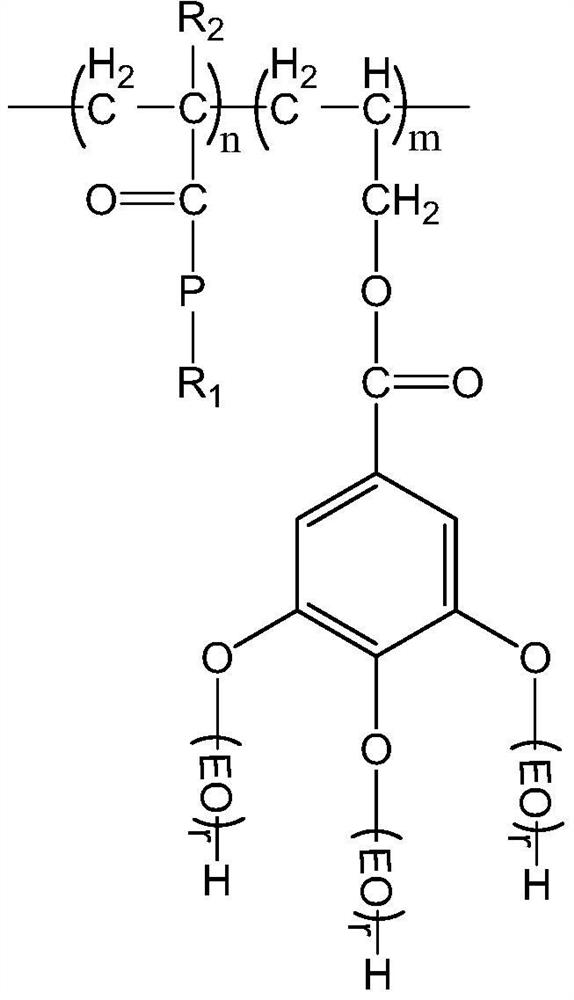

An anti-cracking and shrinkage-reducing polycarboxylate water reducer and its preparation method

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of anti-cracking and shrinkage polycarboxylate water reducing agent and its preparation, which can solve the problem of reducing the surface tension of the solution inside the cement slurry void, reducing the feasibility of industrial production, and lacking market competitiveness and other problems, to achieve excellent dispersion and retention effect, excellent crack resistance and shrinkage reduction performance, and safe and reliable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of prepolymerized product of anti-cracking and shrinkage-reducing superplasticizer: 1 mol of gallic acid and 4 mol of acetic anhydride were stirred and reacted at 50° C. for 3 h under the catalytic condition of concentrated sulfuric acid (0.2 mL), washed with water, and then reacted with propylene chloride at room temperature. Reaction for 24h to obtain gallic acid derivative unsaturated small monomer; the obtained small monomer (0.3mol), acrylic acid (3mol) in 50mL methanol with ammonium persulfate (0.1mol), sodium bisulfite (0.1mol) and 2-mercaptopropionic acid (0.08mol) was used together, and the prepolymerized product was obtained by carrying out free radical polymerization at 20°C for 4 hours;

[0035] 2) Add sodium hydroxide to the obtained prepolymerized product to make the solution pH 7-8, remove the protective group and then evaporate the solvent; continue to add the terminal halogen group modified polyether (1 mol, M w =1000g / mol) of 120mL aceto...

Embodiment 2

[0040] 1) Preparation of prepolymerized product of anti-cracking and shrinkage-reducing superplasticizer: 1 mol of gallic acid and 4 mol of acetic anhydride were stirred and reacted at 50° C. for 3 h under the catalytic condition of concentrated sulfuric acid (0.2 mL), washed with water, and then reacted with propene bromide at room temperature. Reaction for 24h to obtain gallic acid derivative unsaturated small monomer; the obtained small monomer (0.3mol), methacrylic acid (3.5mol) in 50mL acetone with hydrogen peroxide (0.15mol), sodium sulfite (0.08mol) and 3- Combined with mercaptopropionic acid (0.07mol), the prepolymerized product was obtained by performing radical polymerization at 30°C for 3.5 hours;

[0041] 2) adding potassium hydroxide to the obtained prepolymerized product to make the pH of the solution 7-8, removing the protective group and then evaporating to remove the solvent; continue to add the terminal halogen group modified polyether (1 mol, M w =800g / mol) ...

Embodiment 3

[0046]1) Preparation of prepolymerized product of anti-cracking and shrinkage-reducing superplasticizer: 1 mol of gallic acid and 4 mol of acetic anhydride were stirred and reacted at 50° C. for 3 h under the catalytic condition of concentrated sulfuric acid (0.2 mL), washed with water, and then reacted with propylene chloride at room temperature. Reaction for 24h to obtain gallic acid derivative unsaturated small monomer; the obtained small monomer (0.3mol), acrylamide (4mol) in 50mL ethanol with potassium persulfate (0.1mol), sodium metabisulfite (0.12mol) and 2 - Combined with mercaptopropionic acid (0.08mol), the prepolymerized product was obtained by performing free radical polymerization at 30°C for 4.5 hours;

[0047] 2) adding triethylamine to the obtained prepolymerized product to make the solution pH 7-8, and then evaporating to remove the solvent after removing the protective group; continue to add terminal halogen group modified polyether (1 mol, M w =3500g / mol) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com