Soaping agent for polyester/cotton/spandex fabric and preparation method of soaping agent

A kind of soaping agent and fabric technology, which is applied in the field of soaping agent for polyester/cotton/ammonia fabrics and its preparation, and can solve the problems of destroying chromophoric groups, poor penetration cleaning effect, dye bond breaking and hydrolysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

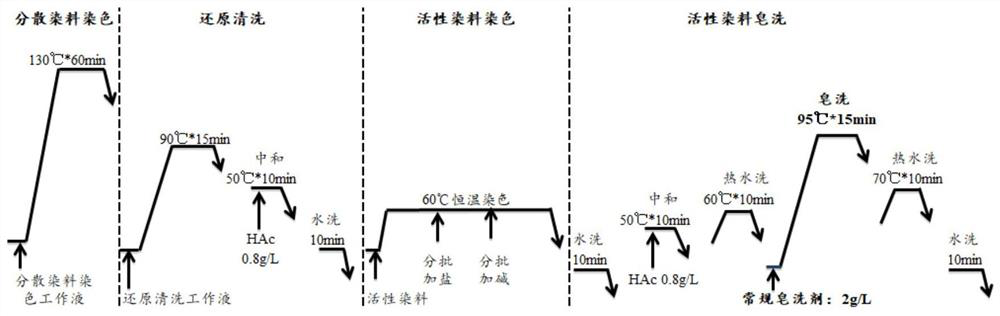

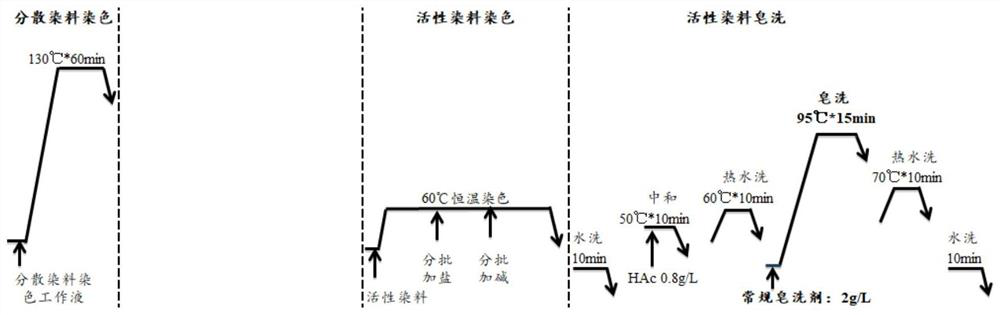

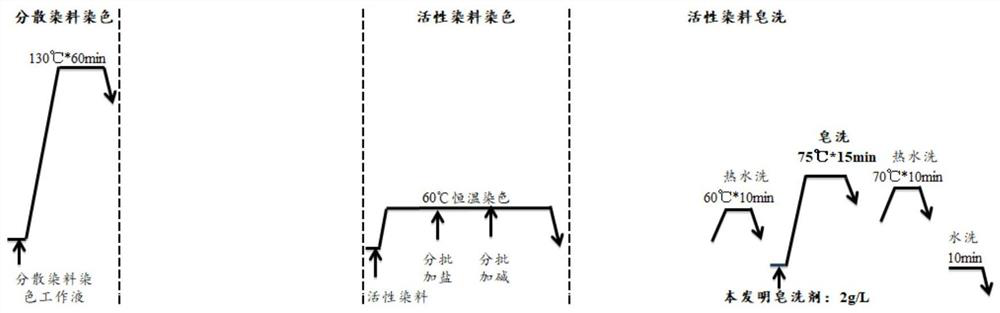

Method used

Image

Examples

preparation example Construction

[0056]The specific preparation process of the acidic trumper copolymer is: mixed with the comonomer represented by the formula (C) and a proper amount of deionized water, stirred at 30-40 ° C for 10-20 min, and the nitrogen gas is heated to 60-95 ° C. At the same time, the copolymer solution represented by the formula (D), the formula (E), as well as the initiator greasehenylmeloyl, acetone is a solvent, and the 1-2 h is added, and the insulation reaction is 1.5-4.5 h, cool to room temperature, The acetone solvent is removed by distillation, that is, acidic terpolymer.

[0057]In a preferred embodiment, the green surfactant is sodium amyl sulfonate, fatty alcohol (C = 10-14) polyoxyethylene ether (EO = 3-10), coconut fatty acid diethanolamide, alkane One or more of the oxosides, α-alkenylsulfonates, polyether foaming agents.

[0058]The present invention also provides the preparation method of the above polyester / cotton / ammonia fabric soapaged, including the steps of:

[0059]1) Add the ...

Embodiment 1

[0065]

[0066]In a four-mouth flask equipped with a stirrer, a thermometer, a reflux condenser, 35 g of dimethylformamide, 99 g (0.10 mol) of 10 hydroxy five-dolla melon, 25.22 g (0.13 mol) phthalic acid, access Nitrogen protection, stirring and warming up to 70 ° C, 0.19 g (0.15% of the total weight of the monomer) titanate, 3.38 g of 2-ethylhexanol, continued to heat up to 215 ° C, heat insulation reaction for 4 h, after cooling Decompression distillation, ie, water-soluble melon ring polymer 1 # (weight average molecular weight: 15890).

[0067]In the four-mouth flask equipped with a stirrer, a thermometer, a reflux condenser, 20.30 g (0.175 mol) maleic acid and 125 g of deionized water, stirred at 35 ° C for 15 min, and the nitrogen gas is warmed to 85 ° C, and add to the nitrogen gas The acetone (20 mL) solution containing 9.36 g (0.045 mol) 3-styrene thiopropate and 36.96 g (0.28 mol) 2-allyl thiionacetic acid, and 2.53 g (3.8% total weight of monomer) The ...

Embodiment 2

[0072]

[0073]In a four-mouth flask equipped with a stirrer, a thermometer, a reflux condenser, 40 g of dimethylformamide, 118.8 g (0.20 mol) of terephthalic acid, 33.20 g (0.20 mol) of terephthalic acid, After nitrogen protection, stir up to 65 ° C, 0.61 g (0.40% of the total weight of the monomer), 6.24 g of 2-ethylhexanol, continued to warm to 180 ° C, thermal insulation reaction 5.5H After cooling, distillation is reduced pressure, i.e., water-soluble melon ring polymer 2 # (weight average molecular weight: 13587).

[0074]In a four-mouth flask equipped with a stirrer, a thermometer, a reflux condenser, 7.84 g (0.08 mol) of maleic anhydride and 150 g of deionized water were added, stirred at 30 ° C for 10 min, and the nitrogen gas was heated to 65 ° C, and added Acetone (30 mL) solution containing 18.72 g (0.09 mol) 3-styrene thiopropionic acid and 52.80 g (0.33 mol) 2-methyll thiopropionic acid, and 1.11 of the total weight of the monomer %) Acetone (2.5 mL)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com