Environment-friendly adhesive capable of being mixed for construction and preparation method of environment-friendly adhesive

An adhesive and environment-friendly technology, applied in adhesives, epoxy resin glue, polyurea/polyurethane adhesive, etc., can solve problems such as insufficient bonding strength, cracking of colored non-slip road surfaces, and large shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

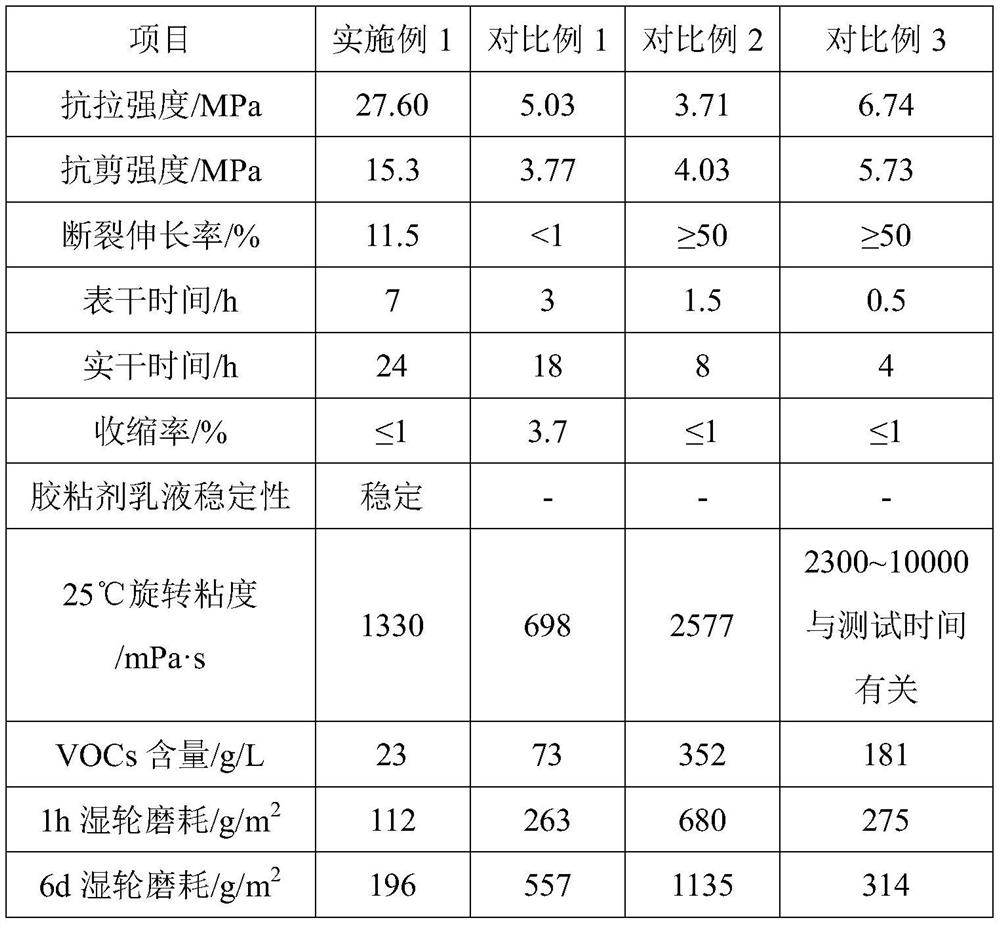

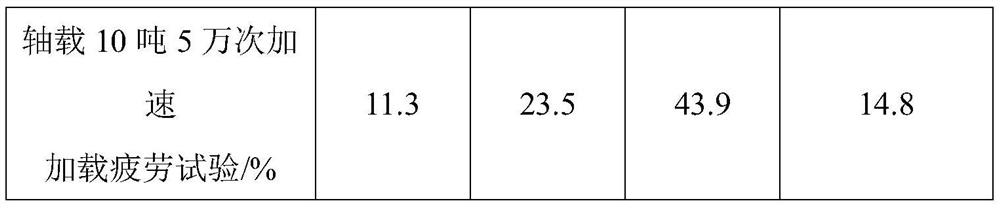

Examples

Embodiment 1

[0032] 1. The preparation method of component A of the environmentally friendly adhesive that can be mixed and mixed:

[0033] 1) Dry castor oil (purity 99.5%), polyethylene glycol 2000, dimethyl carbonate, 4,4'-dicyclohexylmethane diisocyanate (referred to as HMDI) in a vacuum oven at 40°C to remove moisture , then placed in CaCl 2 Place in a desiccator at 25°C for 72 hours;

[0034]2) Dissolve a mixture of 10 molar parts of castor oil and 10 molar parts of polyethylene glycol (molecular weight 2000) into 30 molar parts of dimethyl carbonate, and place it in a reactor at a temperature of 45°C , stir well until completely dissolved, then supply 99.99% N to the reactor 2 Protection, the reactor is heated by an oil bath, the reaction temperature is adjusted to 70°C, the mechanical stirring speed is 3000rpm, and the N 2 A 5°C condensation recovery device is installed at the outlet to collect the evaporated dimethyl carbonate. The reaction process needs to control the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com