Nitrogen dioxide sensor based on composite material blocking effect and preparation method thereof

A blocking effect, composite material technology, applied in the direction of material resistance, can solve the problems of high power consumption and poor gas sensor performance, and achieve the effect of large response, fast response/recovery speed, and good recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

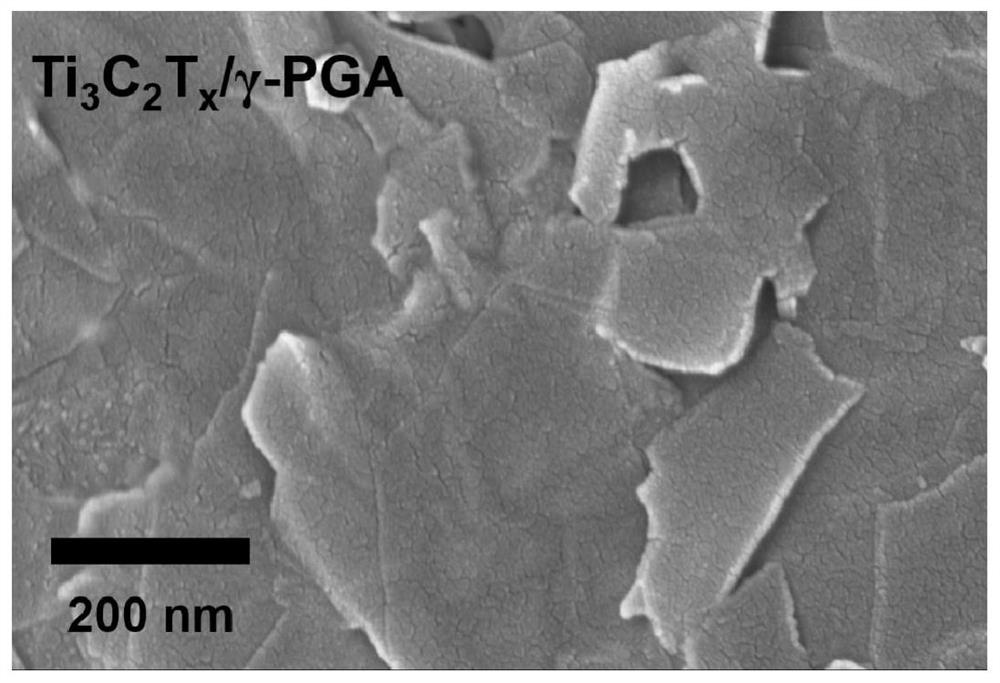

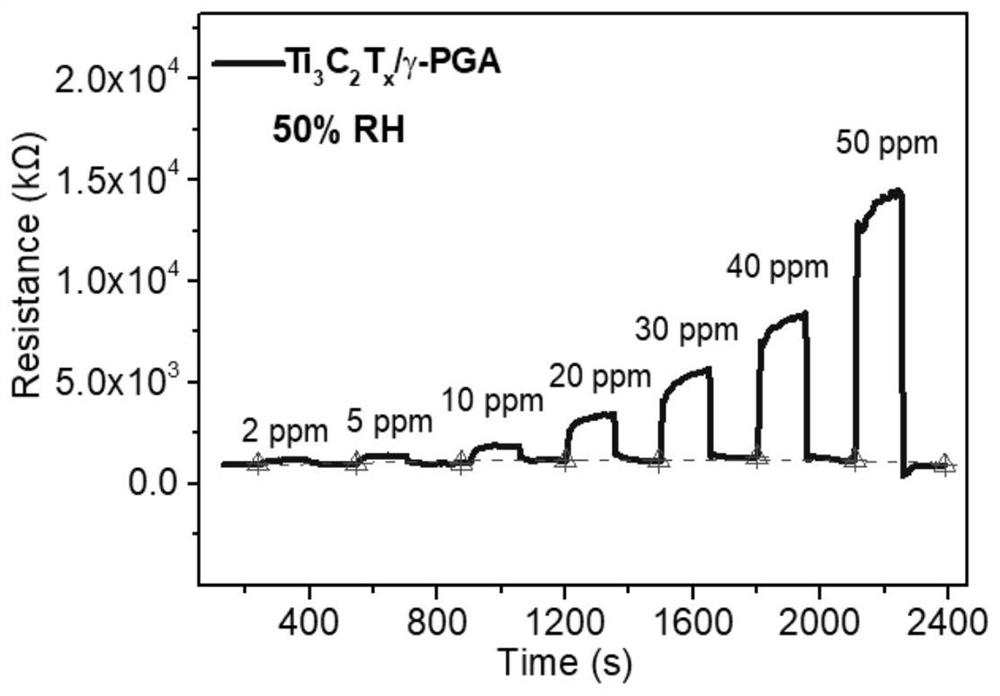

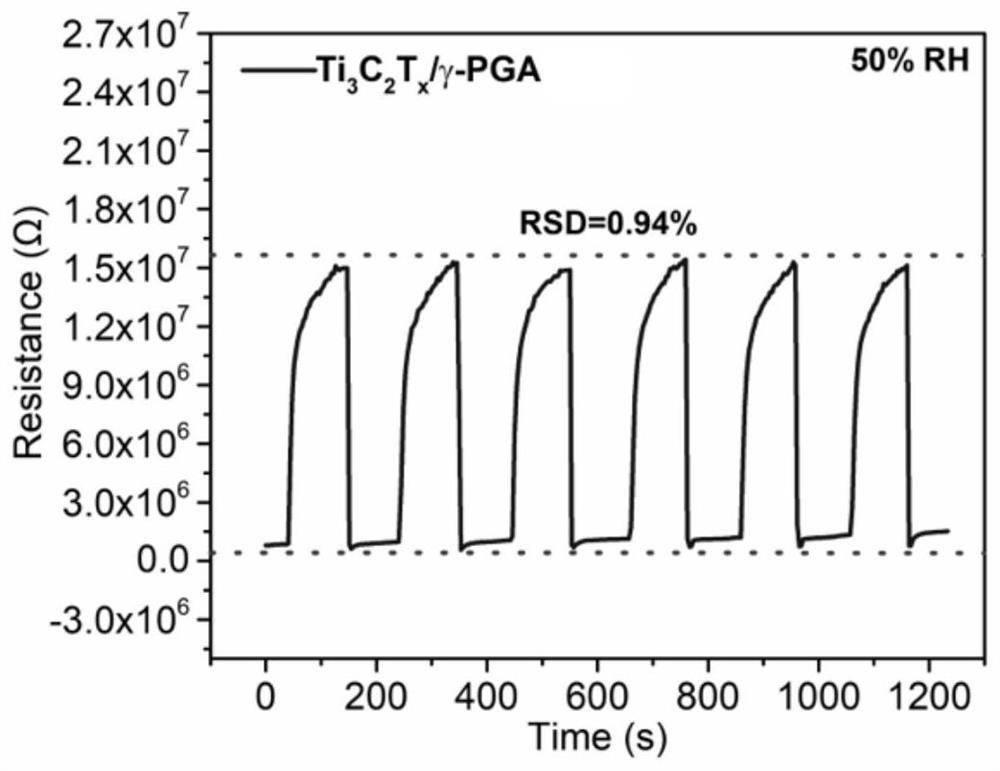

[0034] The sensitive device selected in this embodiment is a flexible interdigital electrode, and the interdigital electrode is a gold electrode made on a flexible polyimide (PI) substrate. The interdigital spacing of the interdigital electrode is 200 μm, and the interdigital width of the interdigital electrode is The electrode thickness of the interdigitated electrode is 200 μm, and the electrode thickness of the interdigitated electrode is 100 nm; in this embodiment, the γ-polyglutamic acid / Ti2C3Tx composite material is selected as the gas sensitive material, and the composite thin film sensitive layer is prepared by a drop coating process, and its specific process steps are:

[0035] (1) Pretreatment of PI substrate gold interdigitated electrodes, cleaning with deionized water, acetone, alcohol and deionized water; dry for later use;

[0036] (2) Prepare the γ-polyglutamic acid dispersion, the solvent is deionized water, configure the γ-polyglutamic acid dispersion with a co...

Embodiment 2

[0041] The sensitive device selected in this embodiment is a flexible interdigital electrode, and the interdigital electrode is a gold electrode made on a flexible polyimide (PI) substrate. The interdigital spacing of the interdigital electrode is 200 μm, and the interdigital width of the interdigital electrode is 200 μm, and the electrode thickness of interdigitated electrode is 100nm; Select gamma-polyglutamic acid / multi-walled carbon nanotube (MWCNTs) composite material as gas-sensitive material in the present embodiment, adopt spraying process to prepare composite film sensitive layer, its concrete The process steps are:

[0042] (1) Pretreatment of PI substrate gold interdigitated electrodes, cleaning with deionized water, acetone, alcohol and deionized water; dry for later use;

[0043] (2) Prepare the γ-polyglutamic acid dispersion, the solvent is deionized water, configure the γ-polyglutamic acid dispersion with a concentration of 1 mg / mL, and use it for later use afte...

Embodiment 3

[0048] In this embodiment, the sensitive device is a flexible interdigital electrode, and the interdigital electrode is a nickel-chromium-gold electrode on a flexible PET substrate. The interdigital spacing of the interdigital electrode is 50 μm, the interdigital width is 50 μm, and the electrode thickness is 100 nm; In this example, the γ-polyglutamic acid / carbon nanofiber composite material is selected as the gas-sensitive material, and the composite film sensitive layer is prepared by a drop coating process, and the specific process steps are as follows:

[0049] (1) Pre-treat the nickel-chromium-gold interdigitated electrode on the PET substrate, wash it with ionized water, acetone, alcohol and deionized water; after drying, perform 10min ultraviolet hydrophilic treatment and set aside;

[0050] (2) Prepare the γ-polyglutamic acid dispersion, the solvent is deionized water, configure the γ-polyglutamic acid dispersion with a concentration of 1 mg / mL, and use it for later us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com