Method for separating iron from pregnant solution leached from automobile exhaust dead catalyst

A technology of waste catalyst and automobile exhaust gas is applied in the direction of improving process efficiency, which can solve the problems of large consumption of zinc powder or magnesium powder, high energy consumption and high cost, and achieve the effect of high recovery rate of precious metals and low process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

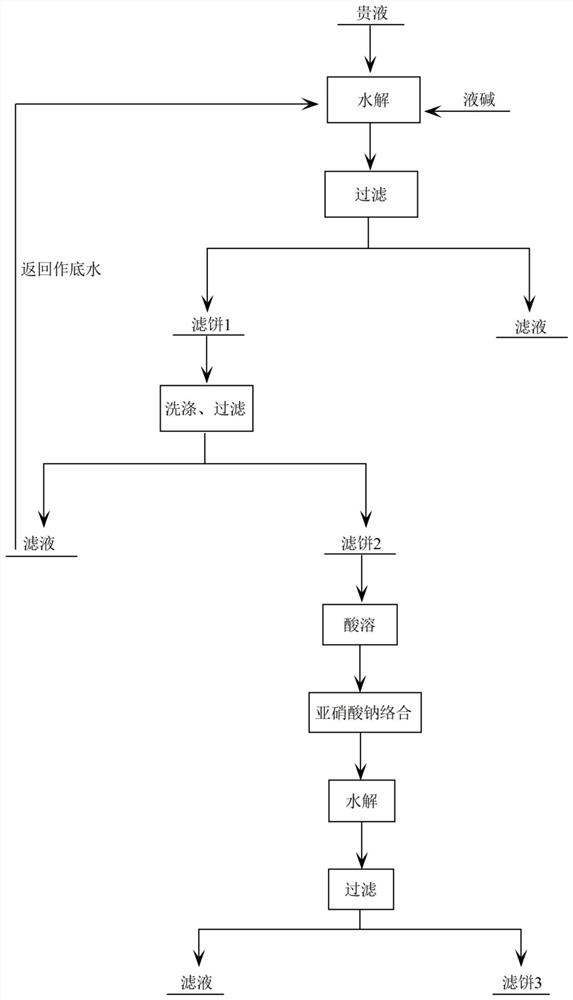

Image

Examples

Embodiment 1

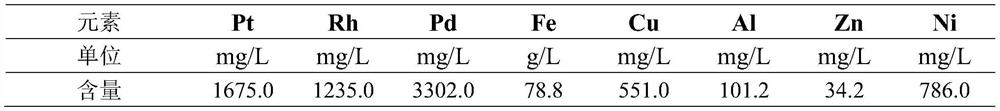

[0017] The composition of a precious liquid is shown in Table 1

[0018] Table 1 Precious liquid composition

[0019]

[0020] The separation method of iron in precious liquid is as follows:

[0021] 1) Hydrolysis: adopt continuous hydrolysis method, add liquid caustic soda and precious liquid into the reaction kettle at the same time, control the pH of the solution at 2.5, control the temperature at 60°C, the iron ion concentration in the precious liquid is 78.8g / L, and add the raw liquid After the completion of the reaction for another 30 minutes, the pH of the solution was always controlled at 2.5, and after the reaction was completed, it was filtered to obtain the first filter cake;

[0022] 2) Washing: wash the first filter cake with dilute hydrochloric acid solution, the pH value of the dilute hydrochloric acid solution is controlled at 2.5, the temperature is controlled at 60°C, stirred and washed for 30 minutes, and filtered to obtain the second filter cake;

[00...

Embodiment 2

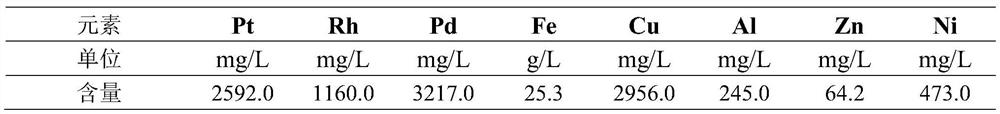

[0026] The composition of a precious liquid is shown in Table 2

[0027] Table 2 Precious liquid composition

[0028]

[0029] The separation method of iron in precious liquid is as follows:

[0030] 1) Hydrolysis: adopt continuous hydrolysis method, add liquid caustic soda and precious liquid into the reaction kettle at the same time, control the pH of the solution at 2.6, control the temperature at 75°C, the iron ion concentration in the precious liquid is 25.3g / L, add the raw liquid After the completion of the reaction for another 50 minutes, the pH of the solution was always controlled at 2.6, and after the reaction was completed, it was filtered to obtain the first filter cake;

[0031] 2) Washing: wash the first filter cake with dilute hydrochloric acid solution, the pH value of the dilute hydrochloric acid solution is controlled at 2.6, the temperature is controlled at 75°C, stirred and washed for 50 minutes, and filtered to obtain the second filter cake;

[0032] ...

Embodiment 3

[0035] The composition of a precious liquid is shown in Table 3

[0036] Table 3 Precious liquid composition

[0037]

[0038] The separation method of iron in precious liquid is as follows:

[0039] 1) Hydrolysis: adopt the continuous hydrolysis method, add liquid caustic soda and precious liquid into the reaction kettle at the same time, control the pH of the solution at 2.7, control the temperature at 85°C, and the concentration of iron ions in the precious liquid is 16.2g / L. After the completion of the reaction for another 70 minutes, the pH of the solution was always controlled at 2.7, and after the reaction was completed, it was filtered to obtain the first filter cake;

[0040] 2) Washing: wash the first filter cake with dilute hydrochloric acid solution, the pH value of the dilute hydrochloric acid solution is controlled at 2.7, the temperature is controlled at 85°C, stirred and washed for 70 minutes, and filtered to obtain the second filter cake;

[0041] 3) Diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com