Purification method of 2-acrylamido-2-methallyl sulfonic acid monomer

A technology of methacrylic sulfonic acid and sodium methacrylic sulfonate, which is applied in chemical instruments and methods, sulfonate preparation, organic chemistry, etc., and can solve the problems of cumbersome treatment process, large amount of polymerization inhibitor, stability impact, etc. problem, to achieve the effect of less process investment and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

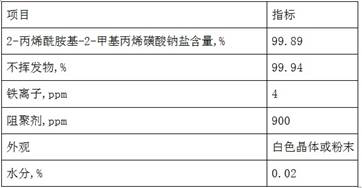

Embodiment 1

[0033] A method for purifying 2-acrylamido-2-methacrylic sulfonic acid monomer, specifically:

[0034] 1. Pretreatment: add unpurified 2-acrylamido-2-methylpropenesulfonic acid monomer to acetone, then add sodium iodide to acetone, stir at a stirring speed of 300rpm for 30min, filter, and put the filter residue in drying at 60°C to obtain 2-acrylamido-2-methylpropenesulfonic acid after primary treatment;

[0035] In the unpurified 2-acrylamido-2-methacrylsulfonic acid, the mass fraction of 2-acrylamido-2-methacrylsulfonic acid was 95.5%, the mass fraction of acrylamide was 1.8%, and the N- The mass fraction of tert-butylacrylamide is 1.1%, the mass fraction of propylamine is 0.4%, the mass fraction of methallyl sulfonic acid is 0.22%, and the dimerization of 2-acrylamido-2-methacrylsulfonic acid The mass fraction of body (or trimer) is 0.04%, and the content of polymerization inhibitor is 30PPM;

[0036] The weight ratio of the unpurified 2-acrylamido-2-methylpropenesulfonic...

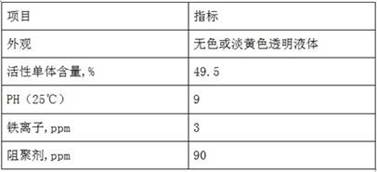

Embodiment 2

[0051] A method for purifying 2-acrylamido-2-methacrylic sulfonic acid monomer, specifically:

[0052] 1. Pretreatment: add the unpurified 2-acrylamido-2-methylpropenesulfonic acid monomer into acetone, then add sodium iodide to the acetone, stir at a stirring speed of 310rpm for 32min, filter, and put the filter residue in Drying at 62°C to obtain 2-acrylamido-2-methylpropenesulfonic acid after primary treatment;

[0053] In the unpurified 2-acrylamido-2-methacrylsulfonic acid, the mass fraction of 2-acrylamido-2-methacrylsulfonic acid is 96%, the mass fraction of acrylamide is 2%, and the N- The mass fraction of tert-butylacrylamide is 1.2%, the mass fraction of propylamine is 0.5%, the mass fraction of methallyl sulfonic acid is 0.24%, and the dimerization of 2-acrylamido-2-methacrylic acid The mass fraction of the body (or trimer) is 0.05%, and the content of the polymerization inhibitor is 35PPM;

[0054] The weight ratio of the unpurified 2-acrylamido-2-methylpropenesu...

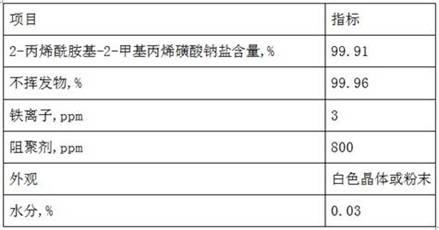

Embodiment 3

[0069] A method for purifying 2-acrylamido-2-methacrylic sulfonic acid monomer, specifically:

[0070] 1. Pretreatment: Add unpurified 2-acrylamido-2-methylpropenesulfonic acid monomer to acetone, then add sodium iodide to acetone, stir at a stirring speed of 320 rpm for 35 minutes, and filter, and put the filter residue in drying at 65°C to obtain 2-acrylamido-2-methylpropenesulfonic acid after primary treatment;

[0071] The mass fraction of 2-acrylamido-2-methylpropenesulfonic acid in the unpurified 2-acrylamido-2-methylpropenesulfonic acid is 96.5%, the mass fraction of acrylamide is 2.2%, and the N- The mass fraction of tert-butylacrylamide is 1.3%, the mass fraction of propylamine is 0.6%, the mass fraction of methallyl sulfonic acid is 0.26%, and the dimerization of 2-acrylamido-2-methacrylic acid The mass fraction of the body (or trimer) is 0.06%, and the content of the polymerization inhibitor is 40PPM;

[0072] The weight ratio of the unpurified 2-acrylamido-2-meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com