Metal adsorbent and sodium hydrosulfide solution purification method using the same

A sodium hydrosulfide and purification method technology, which is applied in the field of metal adsorbent and sodium hydrosulfide solution purification, can solve the problems of high iron content in sodium hydrosulfide, poor reliability, etc., to improve quality, shorten filtration time, and facilitate filtration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] ①Dissolve sodium hydrosulfide in deionized water;

[0029] 2. Add 1wt% metal adsorbent (90wt% of trisodium thiocyanate and 10wt% of insoluble starch xanthate in the metal adsorbent) to the solution obtained in step 1., stir for 10min to separate out impurities;

[0030] ③The liquid obtained in step ② is filtered by a ceramic membrane double filter device lined with polypropylene resin;

[0031] ④ Dilute the solution obtained in step ③ with deionized water to the required concentration, and fill it.

[0032] The metal adsorbent can be eluted from the filter element of the ceramic membrane double filter device and regenerated for use, which is more environmentally friendly.

Embodiment 2-7

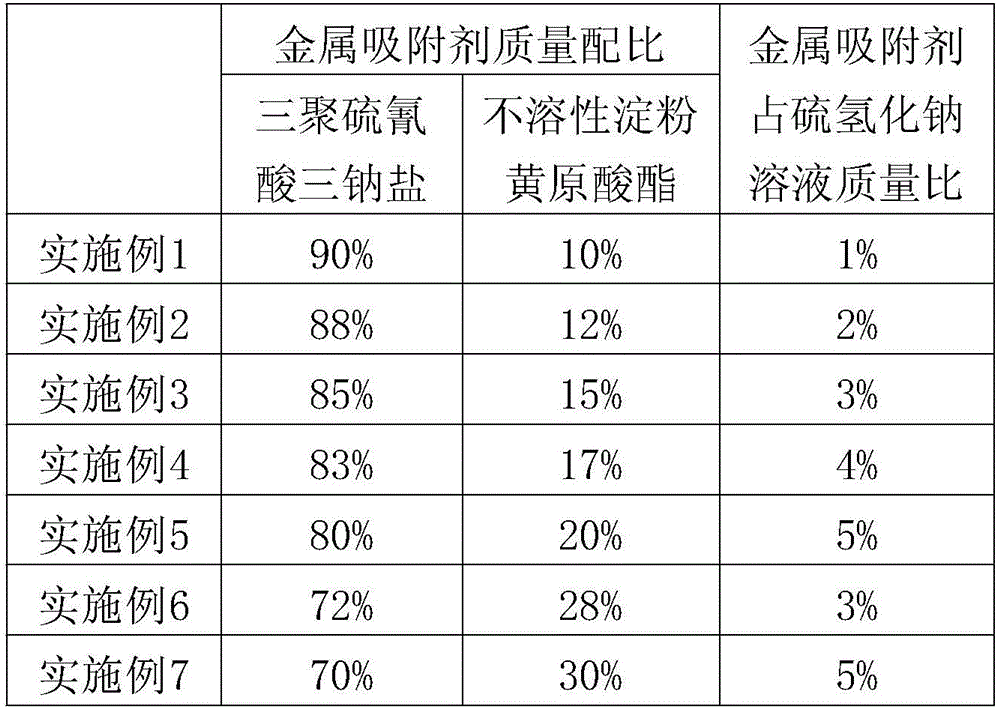

[0034] Repeat the method of Experimental Example 1 according to the mass percentage of each component specified in Table 1 to obtain different sodium hydrosulfide purified solutions.

[0035] Table 1:

[0036]

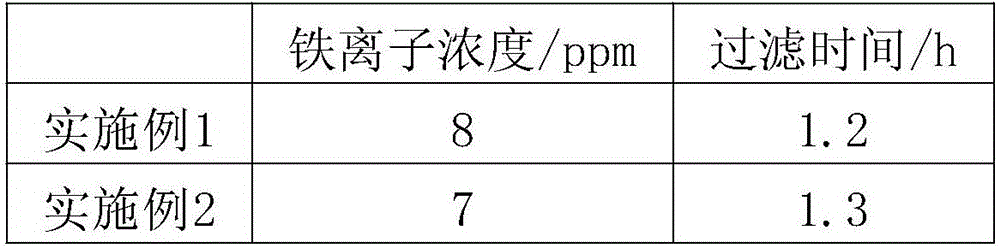

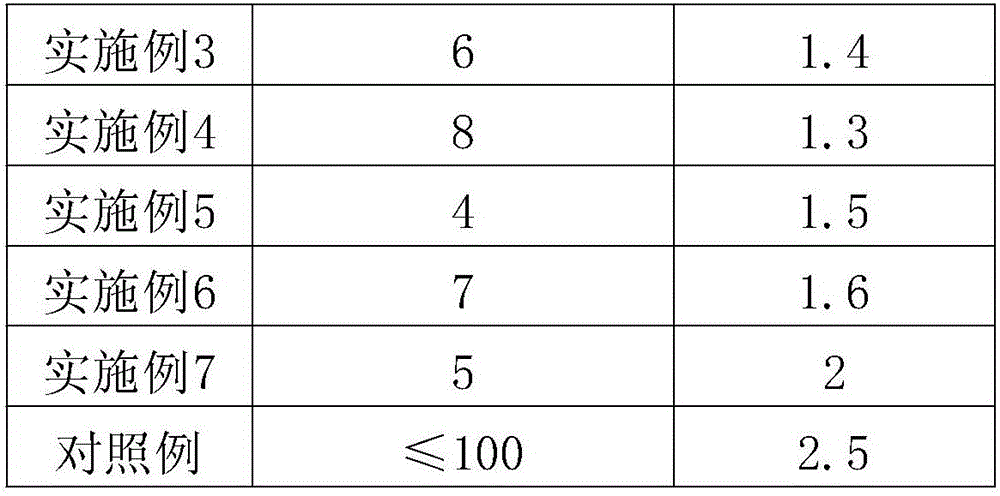

[0037] Trisodium thiocyanate was used as the metal adsorbent to repeat the obtained sodium hydrosulfide purified solution of the method of Example 1 as a control example, and the final iron ion concentration and filtration time of Examples 1-7 and the comparison example were detected and recorded.

[0038] Table 2:

[0039]

[0040]

[0041] Xanthate can make trisodium thiocyanate have better adsorption to iron ions, and can reduce the concentration of iron ions in the solution to below 10ppm, loosen the precipitates produced, significantly shorten the filtration time, and The frequency of filter cleaning is reduced, so it is generally better than the effect of trisodium thiocyanate metal adsorbent.

[0042] The ceramic membrane double filter device can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com