Polyethylene composite material for injection molding and preparation method thereof

A composite material and polyethylene technology, which is applied in the field of polyethylene composite materials for injection molding and its preparation, can solve the problems of poor high and low temperature resistance, short service life and low impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

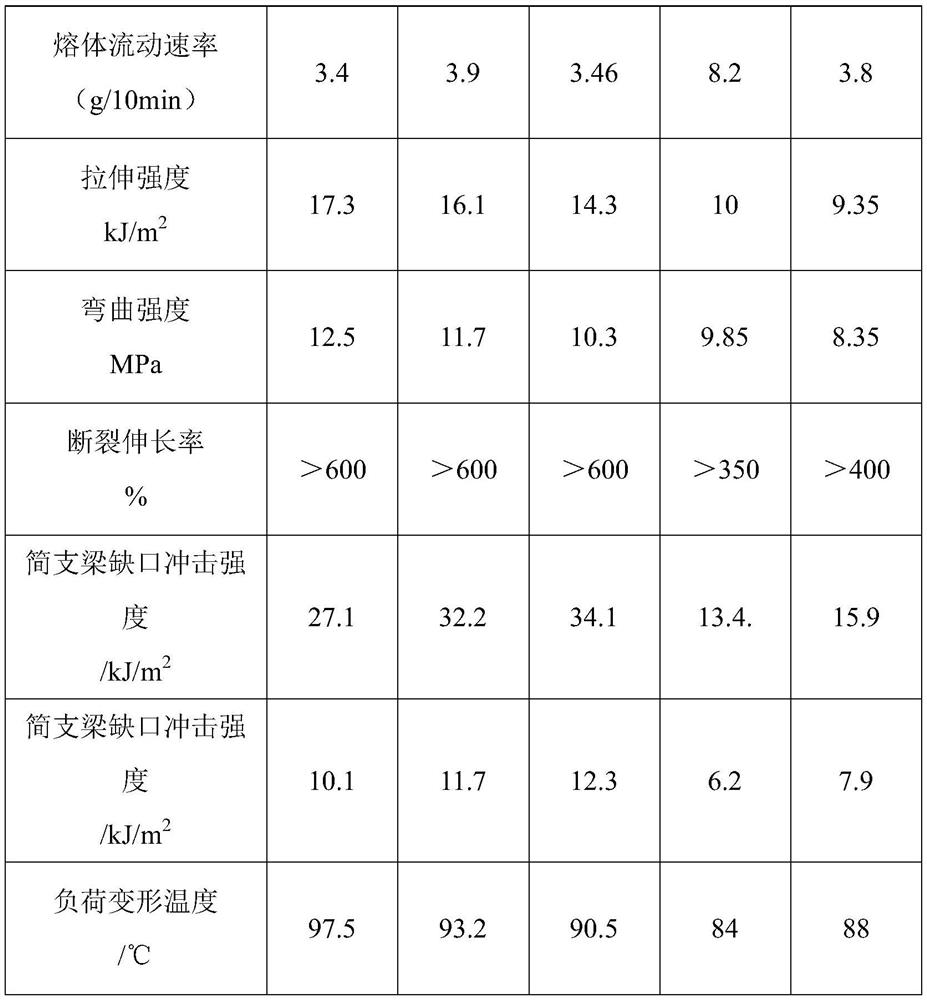

Embodiment 1

[0041] The polyethylene composite material for injection molding of this embodiment is prepared from the following raw materials and auxiliary agents in parts by weight:

[0042] 30 parts of coupling agent modified calcium carbonate, 70 parts of high-density polyethylene, 20 parts of DFDA-7042 linear low-density polyethylene, 10 parts of POE toughening agent, 0.3 parts of UV-327 light stabilizer, main antioxidant (antioxidant Oxygen agent 2246) 0.6 part, secondary antioxidant (antioxidant DLTP) 0.5 part, dispersant PE wax 0.2 part and colorant amount.

[0043] The grade of high-density polyethylene is DMDA-8008.

[0044] The coupling agent modified calcium carbonate is prepared from the following raw materials in parts by weight: 30 parts of calcium carbonate powder and 0.5 part of T-671 titanate coupling agent.

[0045] The polyethylene composite material for injection molding in this embodiment can be used for large-scale injection molding products such as turnover boxes, f...

Embodiment 2

[0047] The polyethylene composite material for injection molding of this embodiment is prepared from the following raw materials and auxiliary agents in parts by weight:

[0048] 20 parts of coupling agent modified calcium carbonate, 60 parts of high-density polyethylene, 40 parts of DFDA-7042 linear low-density polyethylene, 20 parts of POE toughening agent, 0.3 part of UV-327 light stabilizer, main antioxidant (antioxidant Oxygen agent 2246) 0.6 part, secondary antioxidant (antioxidant DLTP) 0.5 part, dispersant PE wax 0.2 part and colorant amount.

[0049] The grade of high-density polyethylene is DMDA-8008.

[0050] The coupling agent modified calcium carbonate is prepared from the following raw materials in parts by weight: 20 parts of calcium carbonate powder and 0.3 part of T-671 titanate coupling agent.

[0051] The polyethylene composite material for injection molding in this embodiment can be used for large-scale injection molding products such as trailer-type sanit...

Embodiment 3

[0053] The polyethylene composite material for injection molding of this embodiment is prepared from the following raw materials and auxiliary agents in parts by weight:

[0054] 20 parts of coupling agent modified calcium carbonate, 50 parts of high-density polyethylene, 50 parts of DFDA-7042 linear low-density polyethylene, 15 parts of POE toughening agent, 0.3 parts of UV-327 light stabilizer, main antioxidant (antioxidant Oxygen agent 2246) 0.6 part, secondary antioxidant (antioxidant DLTP) 0.5 part, dispersant PE wax 0.2 part and colorant amount.

[0055] The grade of high-density polyethylene is DMDA-8007.

[0056] The coupling agent modified calcium carbonate is prepared from the following raw materials in parts by weight: 20 parts of calcium carbonate powder and 0.3 part of T-671 titanate coupling agent.

[0057] Two, the specific embodiment of the preparation method of injection molding polyethylene composite material of the present invention is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Charpy notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com