Preparation method of high-performance sintered samarium-cobalt magnet

A samarium-cobalt magnet, high-performance technology, applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of rare earth volatilization and oxidation, long sintering time, rare earth volatilization, etc., to reduce volatilization waste, good Economic benefits, the effect of reducing waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

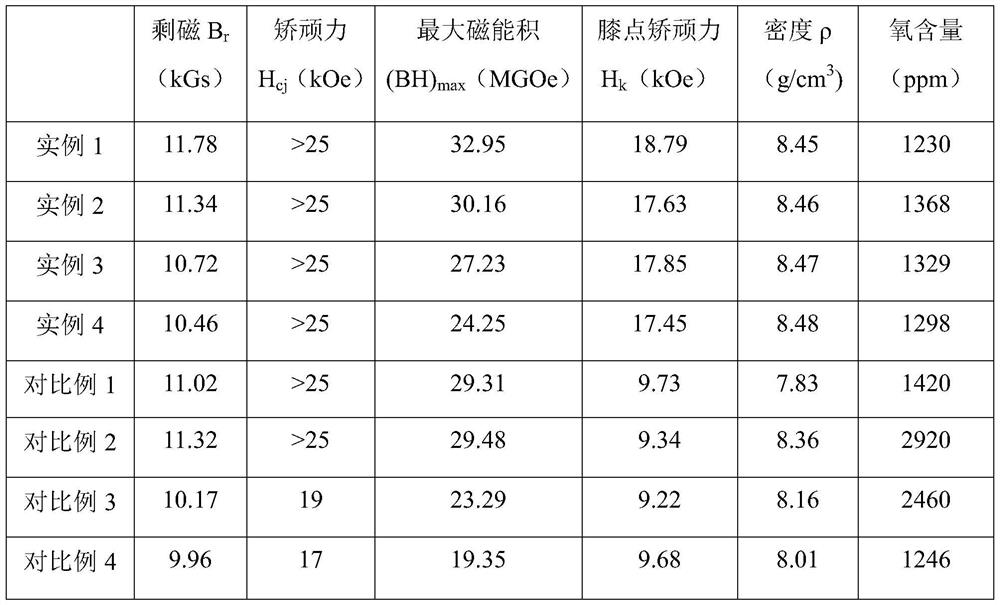

Examples

example 1

[0025] A method for preparing a high-performance sintered samarium-cobalt magnet, including:

[0026] 1) Preparation of ingot:

[0027] Prepare the samarium-cobalt alloy raw material according to the following percentages by weight: 24.6% by weight of Sm, 20.1% by weight of Fe, 2.4% by weight of Zr, 4.6% by weight of Cu, and the balance being Co;

[0028] The prepared samarium-cobalt alloy raw material was melted and casted in a pure argon atmosphere, the melting was carried out in an intermediate frequency melting furnace, and the casting was carried out in a pan-cooled water-cooled copper mold to obtain an alloy ingot with a thickness of about 10mm;

[0029] 2) Milling:

[0030] Under the protection of nitrogen, the alloy ingot is mechanically crushed, medium crushed, and jet milled to prepare alloy powder with an average particle size of 3.45 μm;

[0031] 3) Powder mixing:

[0032] Add the alloy powder to the lubricant with a total weight of 0.33‰. In order to ensure uni...

example 2

[0038] A method for preparing an ultra-high-performance sintered samarium-cobalt magnet, including:

[0039] 1) Preparation of ingot:

[0040] Prepare the samarium-cobalt alloy raw material according to the following percentages by weight: 23.7% by weight of Sm, 18.1% by weight of Fe, 2.7% by weight of Zr, 5.5% by weight of Cu, and the balance being Co;

[0041] The prepared samarium-cobalt alloy raw material was melted and casted in a pure argon atmosphere, the melting was carried out in an intermediate frequency melting furnace, and the casting was carried out in a pan-cooled water-cooled copper mold to obtain an alloy ingot with a thickness of about 10mm;

[0042] 2) Milling:

[0043] Under the protection of nitrogen, the alloy ingot is mechanically crushed, medium crushed, and jet milled to prepare alloy powder with an average particle size of 3.1 μm;

[0044] 3) Powder mixing:

[0045] Add the alloy powder to a lubricant with a total weight of 0.25‰. In order to ensure...

example 3

[0051] A method for preparing a high-performance sintered samarium-cobalt magnet, including:

[0052] 1) Preparation of ingot:

[0053]Prepare the samarium-cobalt alloy raw material according to the following percentages by weight: 22.4% by weight of Sm, 15.3% by weight of Fe, 3.0% by weight of Zr, 6.2% by weight of Cu, and the balance being Co;

[0054] The prepared samarium-cobalt alloy raw material was melted and casted in a pure argon atmosphere, the melting was carried out in an intermediate frequency melting furnace, and the casting was carried out in a pan-cooled water-cooled copper mold to obtain an alloy ingot with a thickness of about 10mm;

[0055] 2) Milling:

[0056] Under the protection of nitrogen, the alloy ingot is mechanically crushed, medium crushed, and jet milled to prepare alloy powder with an average particle size of 2.55 μm;

[0057] 3) Powder mixing:

[0058] Add the alloy powder to a lubricant with a total weight of 0.4‰. In order to ensure uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com