High-carbon corrosion-wear-resistant cast semi-automatic ball mill lining plate steel and preparation method and application thereof

A corrosion-resistant, wear-resistant, ball mill lining technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of high cost, impact corrosion and wear resistance can not reach the expected service life, etc., to achieve increased content, excellent toughness, The effect of improving the structure of the rust layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

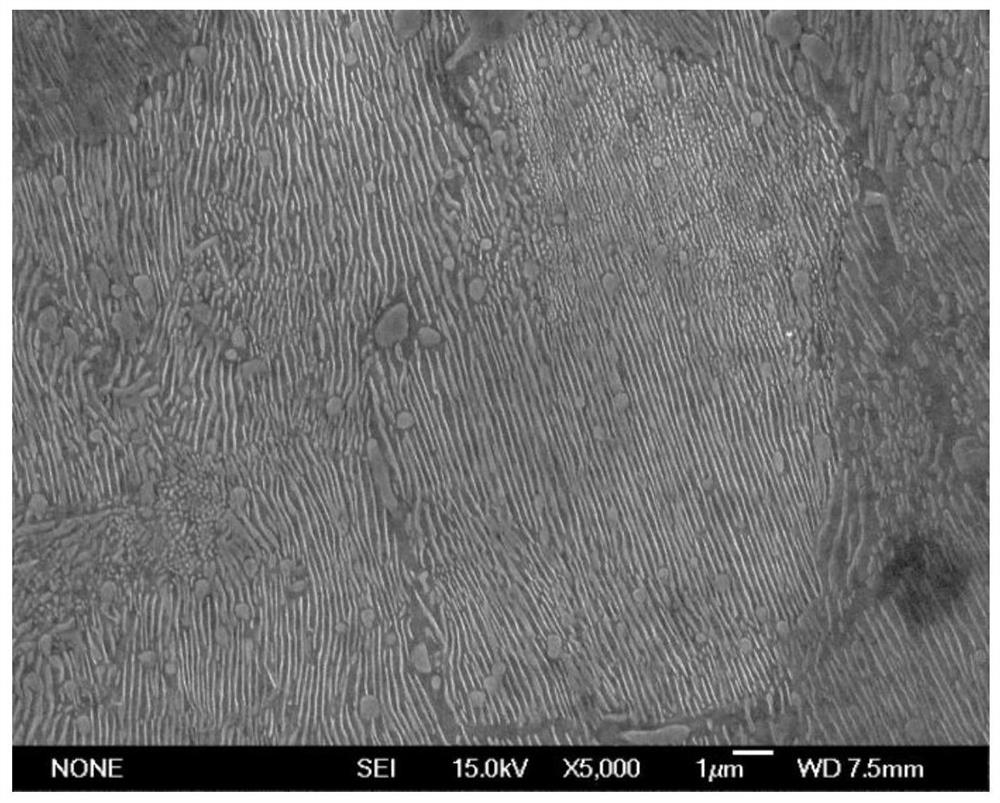

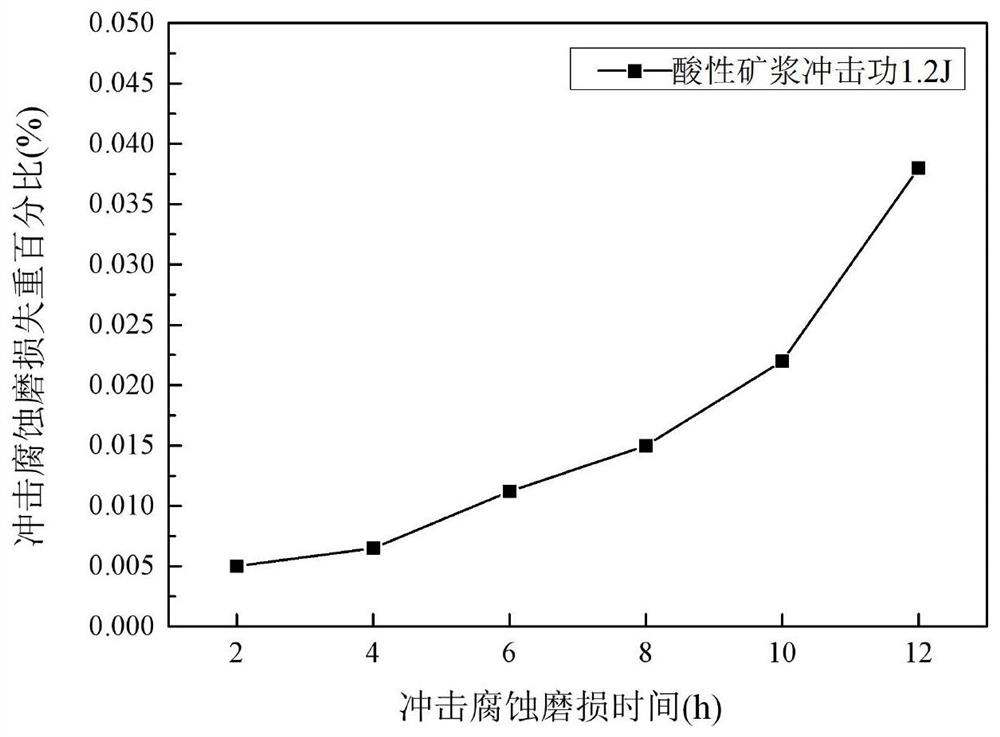

Image

Examples

preparation example Construction

[0040] The present invention provides a method for preparing the high-carbon corrosion-resistant and wear-resistant casting semi-automatic ball mill liner steel described in the technical solution, comprising the following steps:

[0041] According to the raw material ratio of high-carbon corrosion-resistant and wear-resistant cast semi-automatic ball mill liner steel, the corresponding raw materials are smelted and cast in sequence to obtain castings;

[0042] The casting is sequentially subjected to quenching treatment, first tempering treatment and second tempering treatment to obtain a high-carbon corrosion-resistant and wear-resistant casting semi-automatic ball mill liner.

[0043] In the present invention, according to the above raw material ratio, the corresponding raw materials are sequentially smelted and cast to obtain castings. In the present invention, the smelting process preferably includes desulfurization, dephosphorization and slagging, pre-deoxidation, alloyi...

Embodiment 1

[0054] The chemical composition and mass percentage of high-carbon corrosion-resistant and wear-resistant semi-automatic ball mill liner steel are: C 0.6%, Si0.3%, Mn 0.9%, Ni 0.1%, Cr 0.2%, Mo 0.25%, Cu 0.1%, Ti 0.01% , Nb 0.02%, P0.05%, S 0.02%, and the balance Fe and unavoidable impurities.

[0055] The preparation method of the above-mentioned high-carbon corrosion-resistant and wear-resistant semi-automatic ball mill liner steel:

[0056] (1) Melting and casting: accurately calculate the ingredients according to the stated ingredients, and place the raw materials in an intermediate frequency induction melting furnace, using CaO-CaF 2 (the mass percentage added is 0.8% of the total casting amount) to carry out desulfurization, dephosphorization and slag removal, heat up to 1530-1540°C, and use pure aluminum wire for pre-deoxidation for 2min (the amount of aluminum wire added is 0.7kg / ton of steel); continue to heat up The molten steel is subjected to alloying treatment at...

Embodiment 2

[0069] The chemical composition and mass percentage of high-carbon corrosion-resistant and wear-resistant semi-automatic ball mill liners are: C 0.9%, Si0.5%, Mn 1.3%, Ni 0.5%, Cr 0.3%, Mo 0.5%, Cu 0.3%, Ti 0.06%, Nb 0.08%, P 0.05%, S 0.02%, and the balance Fe and unavoidable impurities.

[0070] The preparation method of the above-mentioned high-carbon corrosion-resistant and wear-resistant semi-automatic ball mill liner steel:

[0071] (1) Melting and casting: accurately calculate the ingredients according to the stated ingredients, and place the raw materials in an intermediate frequency induction melting furnace, using CaO-CaF 2 (the mass percentage added is 0.8% of the total casting amount) to carry out desulfurization, dephosphorization and slag removal, heat up to 1530-1540°C, and use pure aluminum wire for pre-deoxidation for 2min (the amount of aluminum wire added is 0.7kg / ton of steel); continue to heat up The molten steel is subjected to alloying treatment at 1550°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com