High-temperature-resistant mold and manufacturing method thereof

A manufacturing method, high temperature resistant technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., which can solve problems such as insufficient corrosion resistance and burning resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A high temperature resistant mold, including by mass percentage: 70wt% of NbC powder, 25wt% of binder phase powder and Mo 2 C powder is 5wt%, and the binder phase powder is Co powder and / or Ni powder.

Embodiment 2

[0024] A high temperature resistant mold, including by mass percentage: NbC powder 85wt%, adhesive phase powder 14wt% and Mo 2 The C powder is 1 wt%, and the binder phase powder is Co powder and / or Ni powder.

Embodiment 3

[0026] A high-temperature resistant mold, including by mass percentage: NbC powder 80wt%, adhesive phase powder 17wt% and Mo 2 The C powder is 3wt%, and the binder phase powder is Co powder and / or Ni powder.

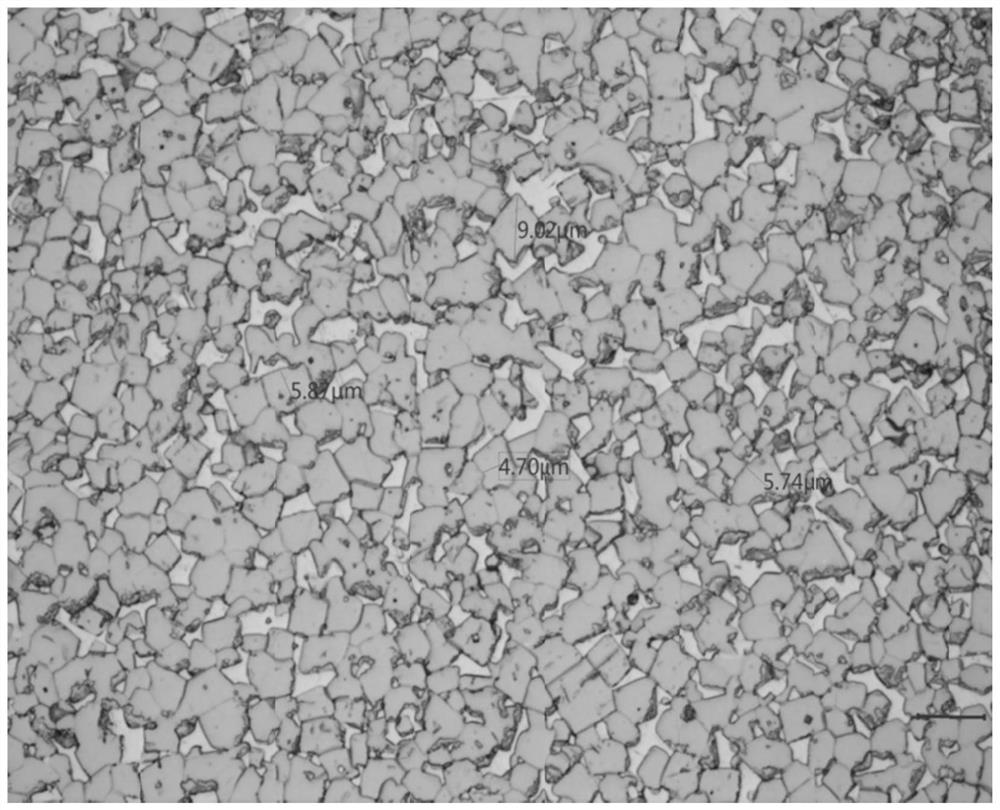

[0027] In the above embodiment, the particle size of the NbC powder is 1.0-2.0 μm, the particle size of the adhesive phase powder is 1.0-1.5 μm, and the Mo 2 The particle size of C powder is 1.0 to 1.5 μm.

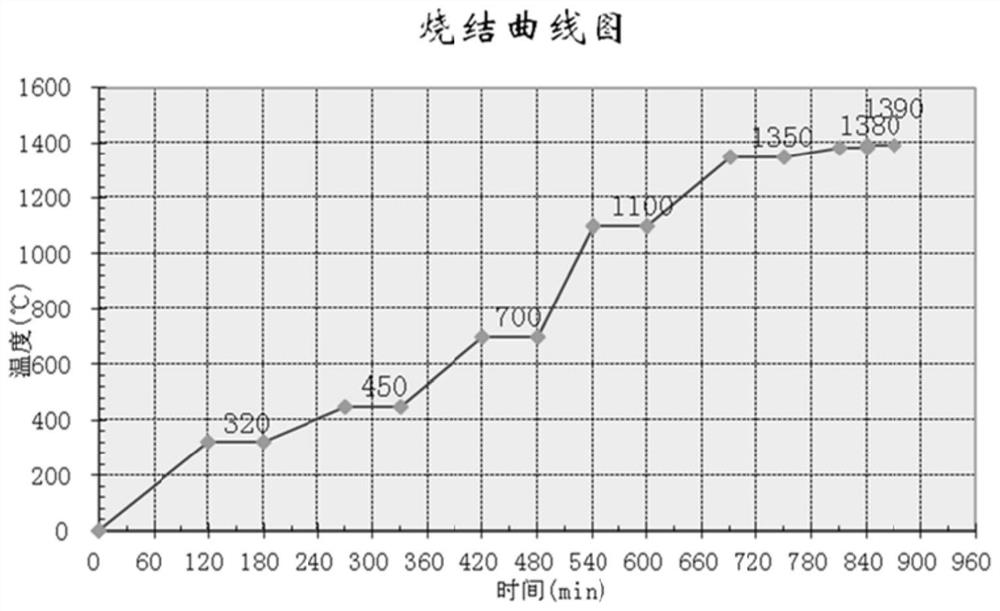

[0028] The manufacturing method of the high temperature resistant mold comprises the following steps in sequence:

[0029] A. Ingredients: NbC powder, Co, Ni powder and Mo 2 C powder is prepared in proportion;

[0030] B. Ball milling into wax: Pour paraffin and oleic acid into a ball mill for ball milling. The proportion of paraffin added is 1.8% to 3.0% of the total weight of the ingredients, and the proportion of oleic acid is 0.05% to 0.2% of the total weight of the ingredients. After mixing evenly, the steps of adding Ingredients and alcohol of A, the amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com