High-dielectric microwave ceramic dielectric material, and preparation method and use thereof

A technology of microwave ceramics and dielectric materials, applied in the field of ceramic dielectric materials, can solve problems such as device reliability decline, material component volatilization, material performance fluctuations, etc., to improve Q*f value, increase grain boundary defects, and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

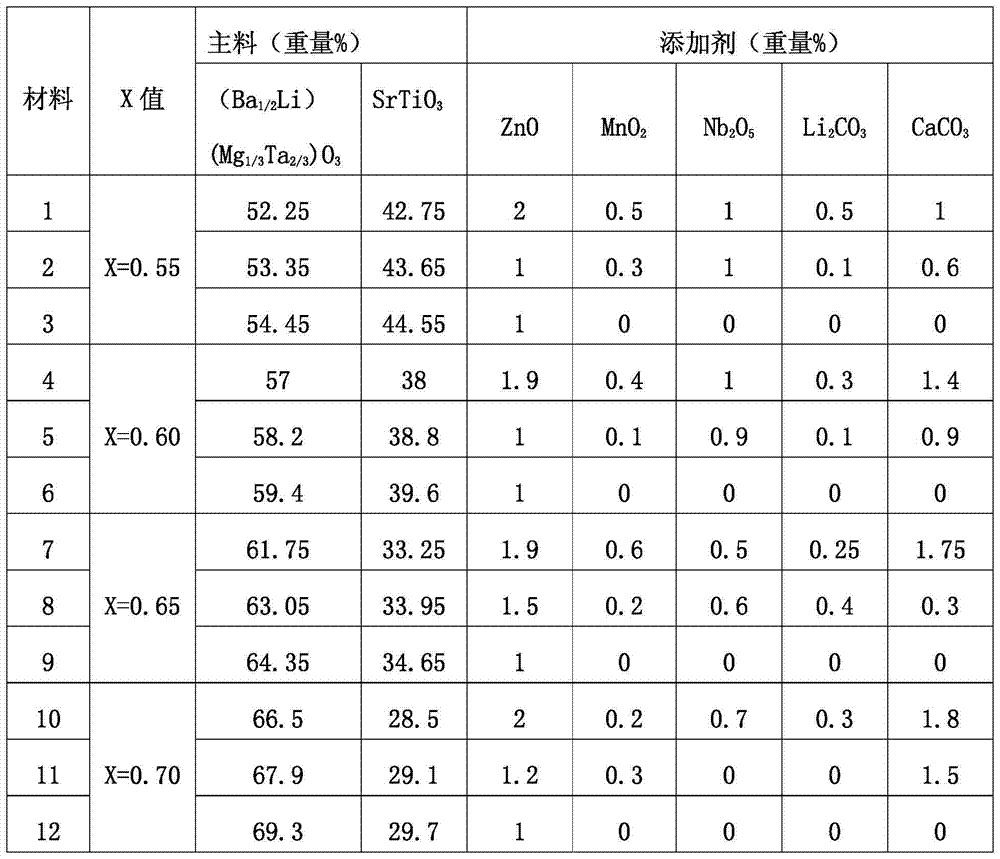

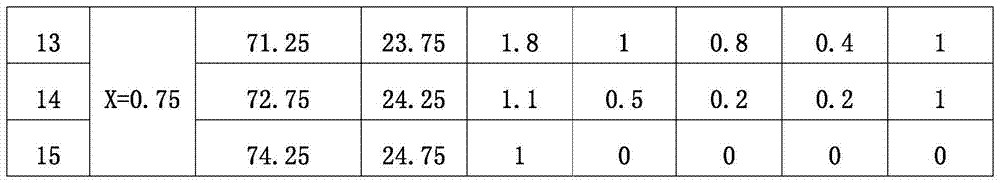

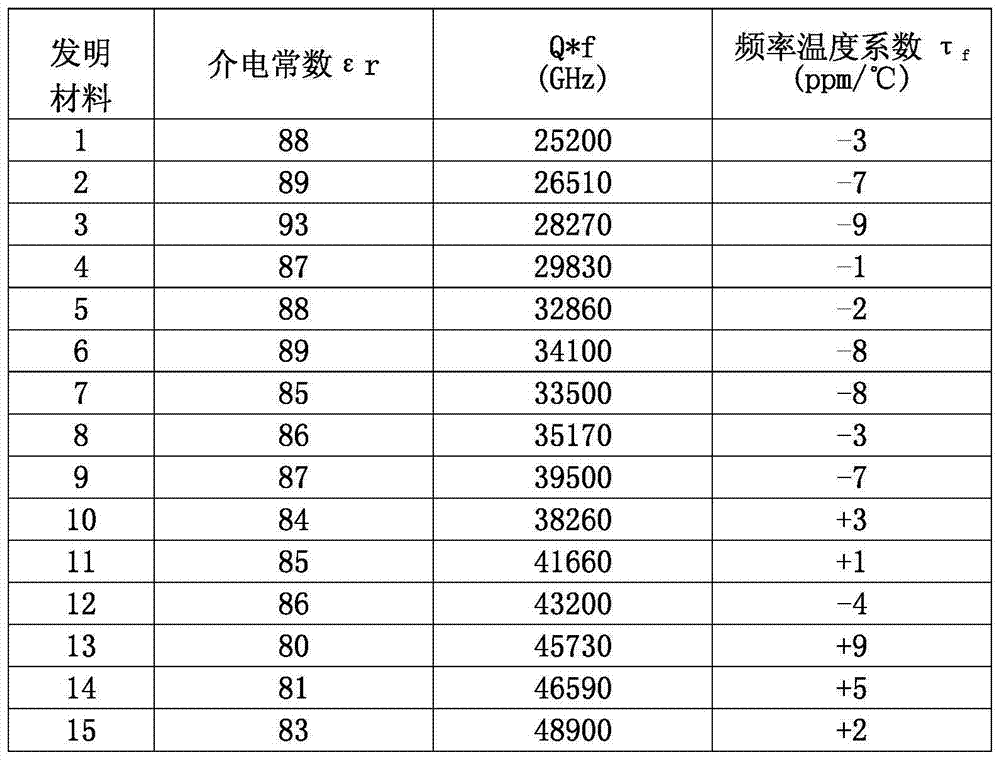

[0024] Embodiment 1: The composition of the microwave ceramic dielectric material in this embodiment is shown in Table 1 and Table 2.

[0025] The preparation of the microwave ceramic dielectric material in this embodiment is as follows:

[0026] (1) Preparation of major ingredients: with barium chloride, strontium chloride, magnesium chloride, titanium chloride, and tantalum chloride as raw materials, they are prepared into aqueous solutions with a concentration of 2mol / L respectively, according to the ratio of each component in the major ingredients Mix, add ammonium bicarbonate or sodium bicarbonate as a precipitant according to 1.5 times the mole fraction of the raw materials, and use the chemical co-precipitation method to generate a precursor precipitate. After filtering and washing, lithium carbonate is used as a raw material. According to the main material The proportion of each component in the mixture is mixed with the precursor precipitate, stirred uniformly, dried,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com