Cadmium telluride thin-film solar cell with gradient structure and manufacture method thereof

A solar cell and gradient structure technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing carrier recombination, reducing Voc and FF values, etc., to improve efficiency, facilitate absorption, and avoid abnormal growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with embodiment the present invention will be further described.

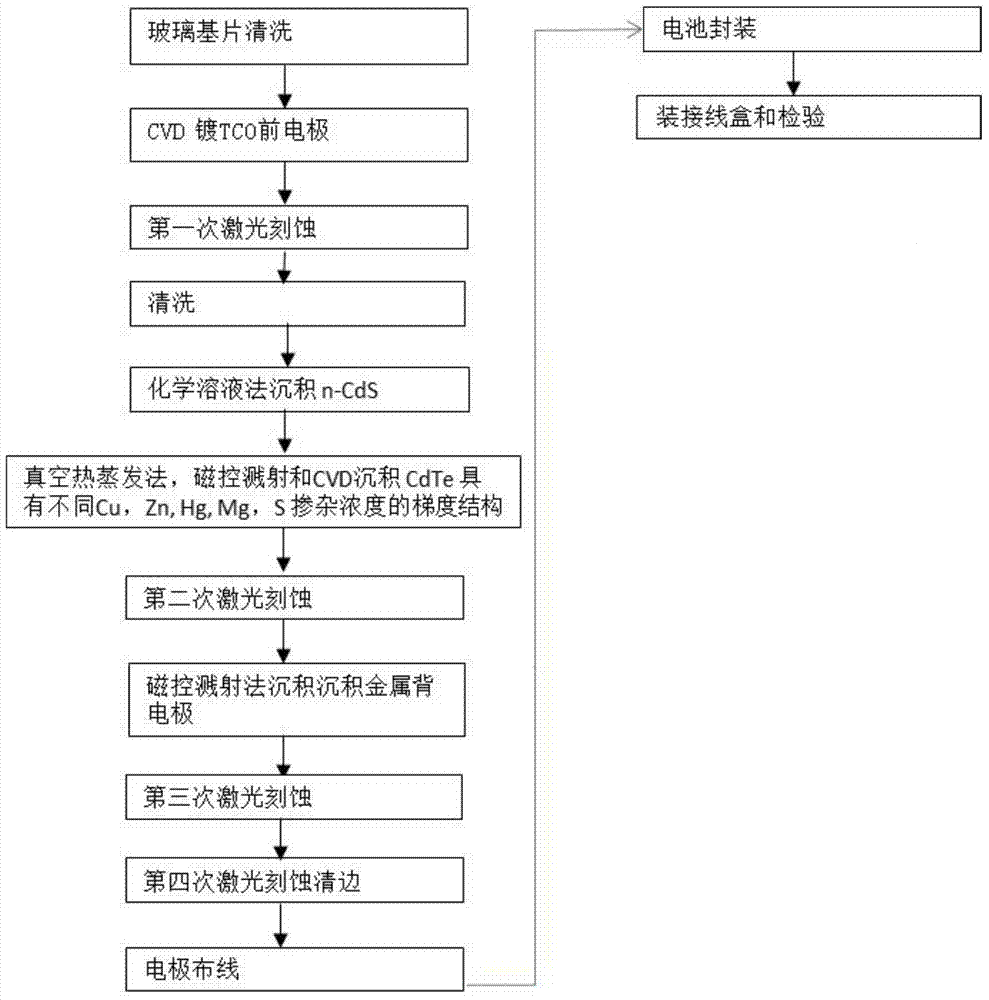

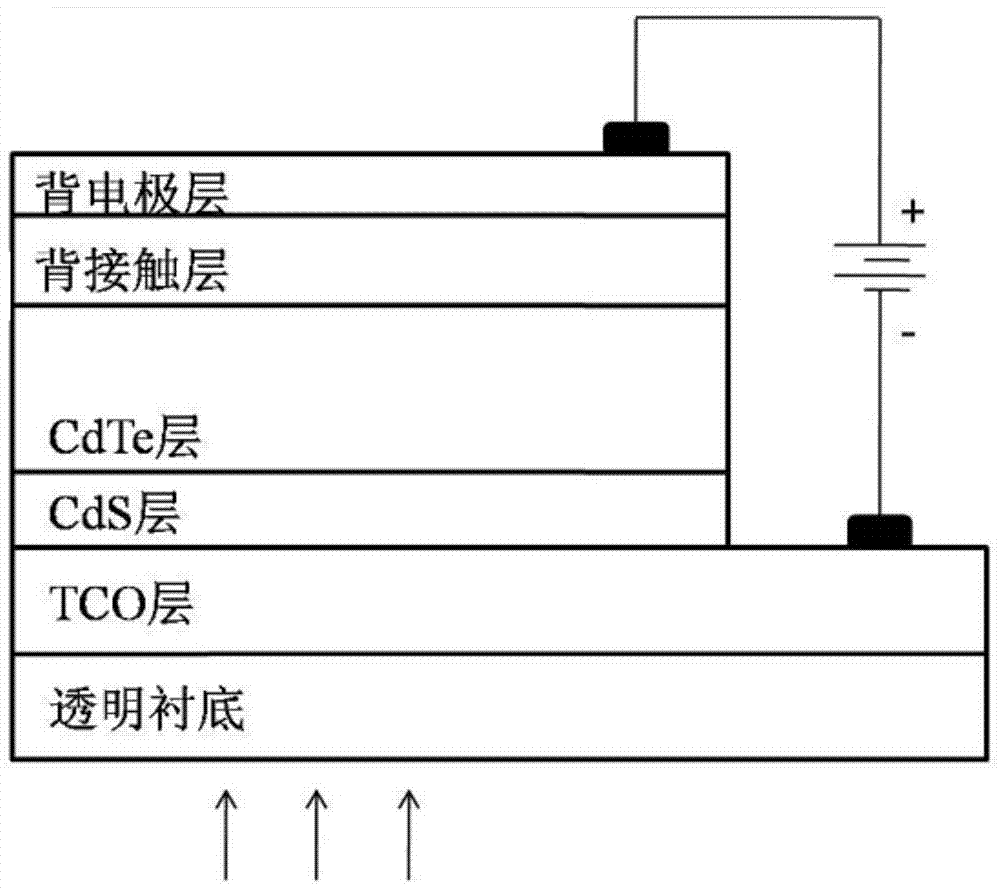

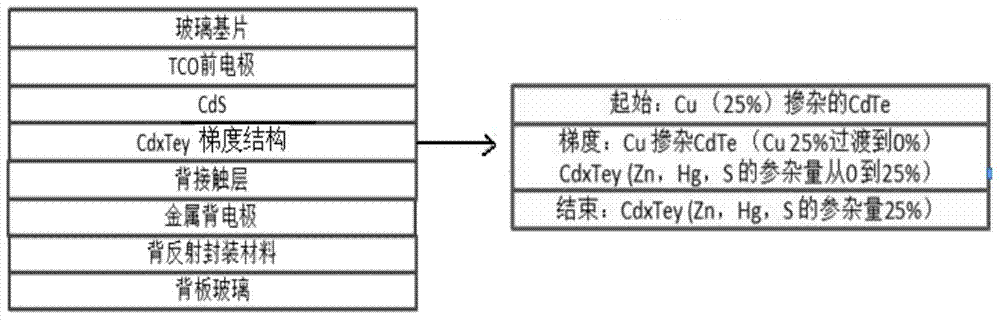

[0043] Such as Figure 2-4 As shown, a cadmium telluride thin-film solar cell with a gradient structure, according to the direction of incident light, sequentially includes a glass substrate, a TCO front electrode, a CdS window layer, a CdTe absorber layer, a back contact layer, a metal back electrode, and a back reflection package Materials and backplane glass, where the CdTe absorber layer (p layer) and the CdS window layer (i layer) form a pn junction.

[0044] The CdTe absorption layer in the pn junction of the cadmium telluride thin film solar cell is Cd x Te y Gradient structure, wherein 0≤x≤1, 0≤y≤1, the gradient structure is a multilayer structure with an energy gap gradient; the Cd x Te yThe energy gap of the gradient structure is between 1.6eV-1.3eV, and there is a uniform transition from the first layer to the last layer from the high energy gap layer to the low energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com