Multilayer electromagnetic shielding composite material based on bicontinuous structure and preparation method and application thereof

A composite material and electromagnetic shielding technology, which is applied in the fields of magnetic/electric field shielding, chemical instruments and methods, coatings, etc., can solve problems such as the mismatch between composite materials and air impedance, the reduction of mechanical properties of composite materials, and the inability to meet practical applications. Achieve the effects of improving shielding efficiency, high electromagnetic shielding effectiveness, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

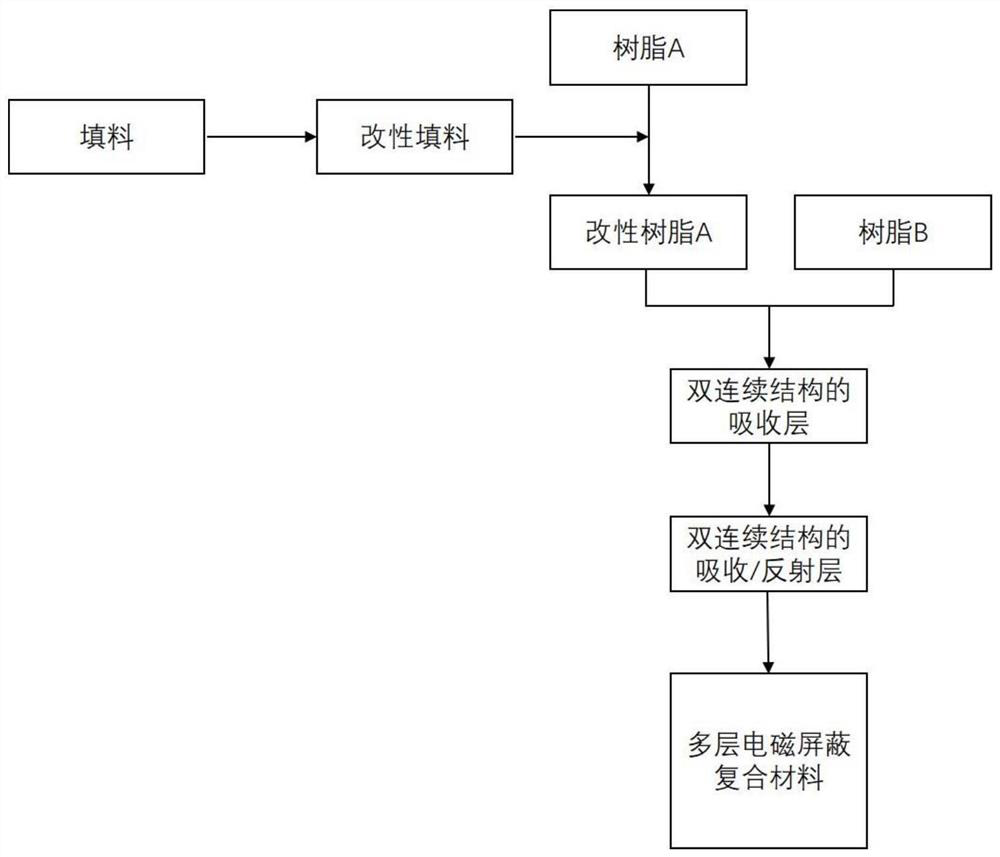

[0091] The invention provides a method for preparing an electromagnetic shielding composite material, comprising the following steps:

[0092] 1) Mix the filler A with the solvent, then add the filler B to continue mixing, then add ferric chloride, alkali and hydrazine hydrate and mix again, then react to obtain the modified filler;

[0093] 2) Extrude and granulate the modified filler and resin A obtained in the above steps to obtain modified resin A, and then re-extrude and granulate modified resin A and resin B to obtain a double continuous structure modified resin ;

[0094] 3) After hot pressing the bicontinuous structure modified resin obtained in the above steps, a bicontinuous structure modified resin layer is obtained;

[0095] 4) Composite the metal nanowire dispersion liquid after plasma treatment on the bicontinuous structure modified resin layer to obtain the electromagnetic shielding composite material.

[0096] In the present invention, the selection and compo...

Embodiment 1

[0148] 1) Preparation of modified filler:

[0149] First, add 1 g of graphene nanosheets to methanol for ultrasonic dispersion for 3 h, then add 1 g of graphene oxide, continue ultrasonication for 3 h, add 30 g of ferric chloride, 150 g of sodium hydroxide and 3.75 g of hydrazine hydrate to the above dispersion Stirring for 4 hours, the above mixture was transferred to an autoclave and treated at 200°C for 16 hours. Finally, filter and wash after cooling down to room temperature, and dry at 120°C to obtain the final modified filler.

[0150] 2) Preparation of double continuous structure modified resin:

[0151] Weigh 2g of polyethylene and 3g of modified filler, and extrude and granulate through extruder at a temperature of 160-220° C. and a rotational speed of 30 rpm to obtain modified polyethylene. 5 g of polyurethane and 5 g of modified polyethylene were extruded and granulated through an extruder at a temperature of 160-220° C. and a rotational speed of 30 rpm to obtain ...

Embodiment 3

[0178] 1) Preparation of modified filler:

[0179] First, add 1g of expanded graphite into ethylene glycol and ultrasonically disperse for 2h, then add 0.75g of graphene oxide, continue ultrasonication for 2h, add 15g of ferric chloride, 60g of sodium hydroxide and 1.67g of hydrazine hydrate into the above dispersion After stirring for 3 h, the above mixed solution was transferred to an autoclave and treated at 180° C. for 12 h. Finally, filter and wash after cooling down to room temperature, and dry at 100°C to obtain the final modified filler.

[0180] 2) Preparation of double continuous structure modified resin:

[0181] 3g of polyvinylidene fluoride and 2g of modified filler were weighed, and the modified polyvinylidene fluoride was obtained by extruding and pelletizing at a temperature of 190-230° C. and a rotational speed of 30 rpm. 5 g of polyurethane and 5 g of modified polyvinylidene fluoride are extruded and granulated through an extruder at a temperature of 190-23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com