Preparation method for graphene and metal composite electromagnetic shielding film

An electromagnetic shielding film, metal composite technology, applied in metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of large-scale continuous preparation of difficult graphene films, achieve rapid absorption and conversion of energy, Wide source of raw materials, the effect of improving absorption and conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) 1 g of graphene oxide and 5 g of deionized water were treated at 20° C. with a 50 KHz ultrasonic wave for 10 hours to obtain a graphene oxide solution.

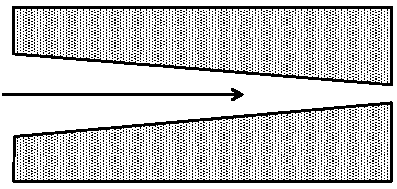

[0034] 2) Extrude the graphene oxide solution at a speed of 200 mL / h in a preparation device with a straight die, stay in the n-butanol coagulation solution at 80°C for 100 seconds to solidify to form a film, and obtain the oxidized graphene membrane.

[0035] 3) The graphene oxide film obtained in step (2) was reduced for 100 hours in an aqueous glucose solution with a mass fraction of 20%, washed and dried to obtain a high-strength graphene film.

[0036] 4) Deposit silver nanoparticles with a thickness of 0.01 μm on the surface of the graphene film obtained in step (3) by vacuum evaporation to obtain a graphene-silver composite electromagnetic shielding film. The vacuum evaporation condition is a vacuum degree of 2 Pa, The metal evaporation temperature is 1000°C.

[0037] After the above steps, the prepared gra...

Embodiment 2

[0039] 1) 1g of graphene oxide and 150g of tetrahydrofuran were ultrasonically treated at 20°C at 50 KHz for 0.1 hour to obtain a graphene oxide solution.

[0040] 2) Extrude the graphene oxide solution at a speed of 100 mL / h in a preparation device with a straight die, stay in ethanol coagulation solution at 10°C for 10 seconds to solidify to form a film, and obtain graphene oxide after drying membrane.

[0041] 3) The graphene oxide film obtained in step (2) was reduced for 1 hour in a hydriodic acid aqueous solution with a mass fraction of 20%, washed and dried to obtain a high-strength graphene film.

[0042] 4) Deposit copper nanoparticles with a thickness of 1000 μm on the surface of the graphene film by chemical electroplating on the graphene film obtained in step (3) to obtain a graphene-copper composite electromagnetic shielding film. The electroplating solution used was 5% copper sulfate solution, the deposition voltage was 7V, the current was 0.5A, and the depositi...

Embodiment 3

[0045] 1) 1g of graphene oxide and 25g of N,N-dimethylformamide were ultrasonically treated at 20°C at 50 KHz for 1 hour to obtain a graphene oxide solution.

[0046] 2) Extrude the graphene oxide solution at a speed of 1000 mL / h in a preparation device with a straight die, stay in methanol coagulating liquid at 60°C for 1 second to solidify to form a film, and obtain graphene oxide after drying membrane.

[0047] 3) The graphene oxide film obtained in step (2) was reduced in 40% hydroiodic acid for 3 hours, washed and dried to obtain a high-strength graphene film.

[0048] 4) The graphene film obtained in step (3) is deposited on the surface of the graphene film with nickel nanoparticles with a thickness of 100 μm by electroless plating to obtain a graphene-nickel composite electromagnetic shielding film. The electroplating uses a mixed aqueous solution of 2% nickel sulfate and 5% nickel chloride, the deposition voltage is 5V, the current is 0.2A, and the deposition time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com