Flexible toughening composition, toughening type epoxy resin adhesive and preparation method of toughening type epoxy resin adhesive

A technology of epoxy resin glue and epoxy resin, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of complex synthesis method, high cost, adverse effects on other properties of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

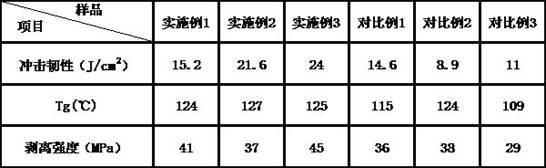

Examples

Embodiment 1

[0027] In this embodiment, the preparation method of the flexible and toughened composition comprises the following steps:

[0028] (1) Prepare the following raw materials in proportion by weight: 67 parts of epoxy resin A (both are bisphenol A type epoxy resin), 24 parts of curing agent A (both are methyl hexahydrophthalic anhydride), diol 8 parts (both are ethylene glycol), 0.5 parts of curing accelerator A (both are triphenylethylphosphonium bromide), 0.15 parts of coupling agent (both are γ-glycidyl etheroxypropyltrimethoxysilane) and 12 parts of inorganic nanoparticles (both alumina powder with a particle size of 20nm);

[0029] (2) Add the raw materials prepared in step (1) into a dry reaction container, stir until they are evenly mixed (stirring for 30 minutes) to obtain a mixed material; then put the mixed material in an oven for reaction, and the reaction condition is 120°C Pre-react at low temperature for 2 hours, and then react at 150° C. for 3 hours. After the rea...

Embodiment 2

[0035] In this embodiment, the preparation method of the flexible and toughened composition comprises the following steps:

[0036] (1) Prepare the following raw materials in proportion by weight: 59 parts of epoxy resin A (including 41 parts of bisphenol A epoxy resin, 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate 18 parts), 30 parts of curing agent A (15 parts of methyl hexahydrophthalic anhydride and 15 parts of methyl tetrahydrophthalic anhydride), 8 parts of diol (both are 1,4 butanediol), curing 0.4 parts of accelerator A (both tetrabutylammonium bromide), 0.2 parts of coupling agent (both 3-aminopropyltriethoxysilane) and 15 parts of inorganic nanoparticles (both are carbon dioxide with a particle size of 50nm silica fume);

[0037] (2) Add the raw materials prepared in step (1) into a dry reaction container, stir until evenly mixed (stirring for 20 minutes), and obtain a mixed material; then put the mixed material in an oven for reaction, and the reaction ...

Embodiment 3

[0043] In this embodiment, the preparation method of the flexible and toughened composition comprises the following steps:

[0044] (1) Prepare the following raw materials in proportion by weight: 56 parts of epoxy resin A (including 28 parts of bisphenol A type epoxy resin and 28 parts of bisphenol S type epoxy resin), 31 parts of curing agent A (of which methyl tetrahydro 20 parts of phthalic anhydride, 11 parts of methyl nadic anhydride), 12 parts of diols (both are 1,3 propylene glycol), 0.6 parts of curing accelerator A (both are triphenylethylphosphonium bromide), 0.25 parts of joint agent (both γ-methacryloxypropyltrimethoxysilane) and 18 parts of inorganic nanoparticles (including 9 parts of alumina powder with a particle size of 20nm and zinc oxide powder with a particle size of 50nm);

[0045] (2) Add the raw materials prepared in step (1) into a dry reaction container, stir until they are evenly mixed (stirring for 20 minutes) to obtain a mixed material; then put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com