A kind of multifunctional foaming water-based resin and preparation method thereof

A water-based resin, multi-functional technology, applied in the field of polymer material preparation, can solve the problems of polluted environment, pungent odor of vulcanizing agent, expensive vulcanizing agent, etc., and achieves high strength, excellent weather resistance, and good film-forming properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

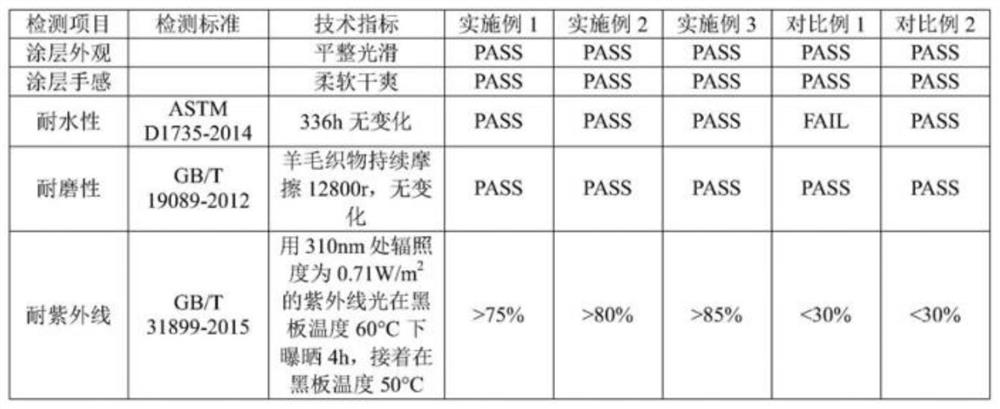

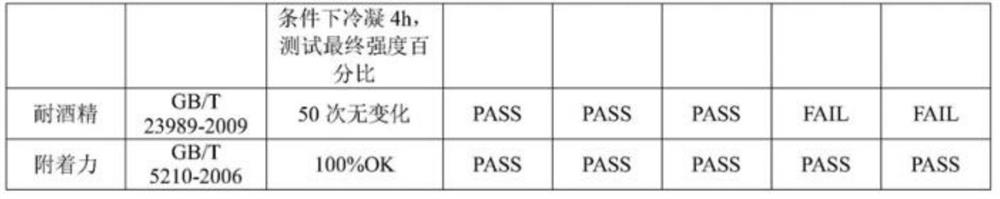

Examples

Embodiment 1

[0039] a. Put 75g of polytetrahydrofuran ether polyol and 5g of modified silicone into a 250mL four-necked flask equipped with a thermometer, agitator and a reflux condenser, heat up to 110°C, and dehydrate for 1h under a vacuum degree of >-0.09MPa, Cool the temperature to 60°C, add 10g of dried anionic chain extender dimethylol butyric acid, stir evenly, put in 15g of isophorone diisocyanate, and react at 90°C for 2h. The temperature was lowered to 70° C., 1.5 g of 1,4-butanediol, a small molecule chain extender, was added, and the reaction was continued at 70° C. for 1 hour. Cool down to <50°C, add catalyst organic bismuth 0.5g and 2 ml of acetone, stir and heat up to 75°C for 4h reaction. Then the temperature was lowered to 20°C, 7g of neutralizer triethylamine and 2ml of acetone were added, and the mixture was stirred for 30min to obtain a prepolymer;

[0040] b. Emulsify the prepolymer. The emulsification process is as follows: add 130 g of deionized water to the flask, ...

Embodiment 2

[0043]a. Put 72g of polytetrahydrofuran ether polyol and 8g of modified silicone into a 250mL four-necked flask equipped with a thermometer, agitator and a reflux condenser, heat up to 110°C, and dehydrate for 1h under a vacuum degree of >-0.09MPa, Cool the temperature to 60°C, add 7 g of dried anionic chain extender dimethylol butyric acid, stir evenly, add 18 g of isophorone diisocyanate, and react at 90°C for 2 hours. The temperature was lowered to 70° C., 1.5 g of 1,4-butanediol, a small molecule chain extender, was added, and the reaction was continued at 70° C. for 1 hour. The temperature was lowered to <50°C, 0.7 g of catalyst organic bismuth and 2 ml of acetone were added, and the temperature was raised to 75°C with stirring for 4 hours. Then cool down to 20°C, add neutralizing agent triethylamine 4g and acetone 2ml, stir for 30min to obtain prepolymer;

[0044] b. Emulsify the prepolymer. The emulsification process is as follows: add 135 g of deionized water to the f...

Embodiment 3

[0047] a. Put 70g of polytetrahydrofuran ether polyol and 10g of modified silicone into a 250mL four-necked flask equipped with a thermometer, agitator and a reflux condenser, heat up to 110°C, and dehydrate for 1h under a vacuum degree of >-0.09MPa, Cool the temperature to 60°C, add 5 g of dried anionic chain extender dimethylol butyric acid, stir evenly, add 18 g of isophorone diisocyanate, and react at 90°C for 2 hours. The temperature was lowered to 70° C., 1.5 g of 1,4-butanediol, a small molecule chain extender, was added, and the reaction was continued at 70° C. for 1 hour. The temperature was lowered to <50°C, 0.9 g of catalyst organic bismuth and 2 ml of acetone were added, and the temperature was raised to 75°C with stirring for 4 hours. Then the temperature was lowered to 20°C, 3 g of neutralizing agent triethylamine and 2 ml of acetone were added, and the mixture was stirred for 30 min to obtain a prepolymer;

[0048] b. Emulsify the prepolymer. The emulsification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com