High-temperature-resistant creep-resistant pipeline thermal insulation material and preparation method thereof

A pipeline insulation and creep resistance technology, applied in the field of polyurethane insulation materials, can solve the problems of decreased shear strength, waste of resources, and reduced performance of polyurethane foam insulation, so as to improve temperature resistance, increase crosslinking degree, reduce The effect of poor temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

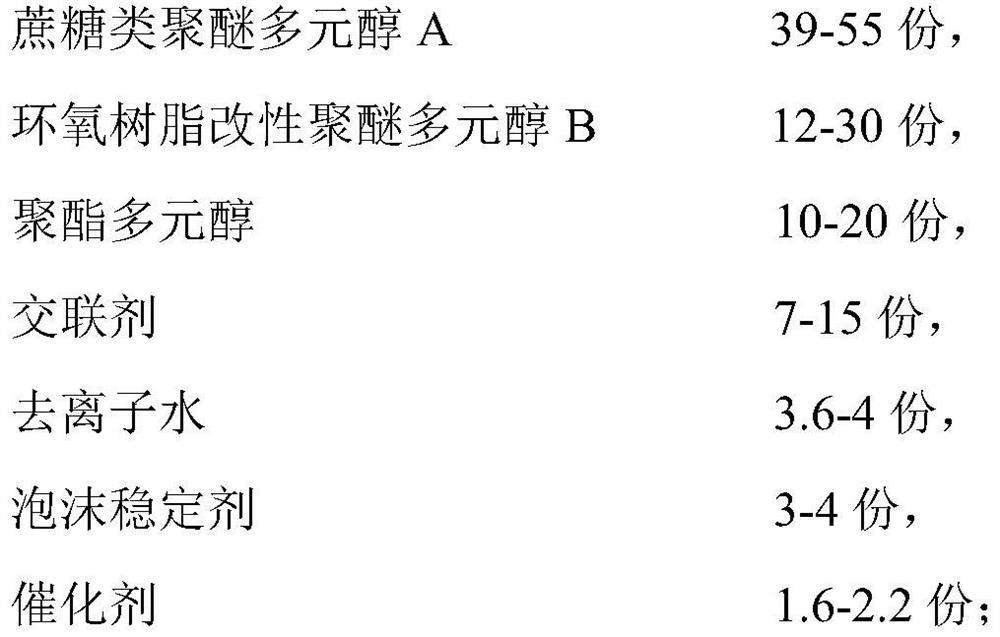

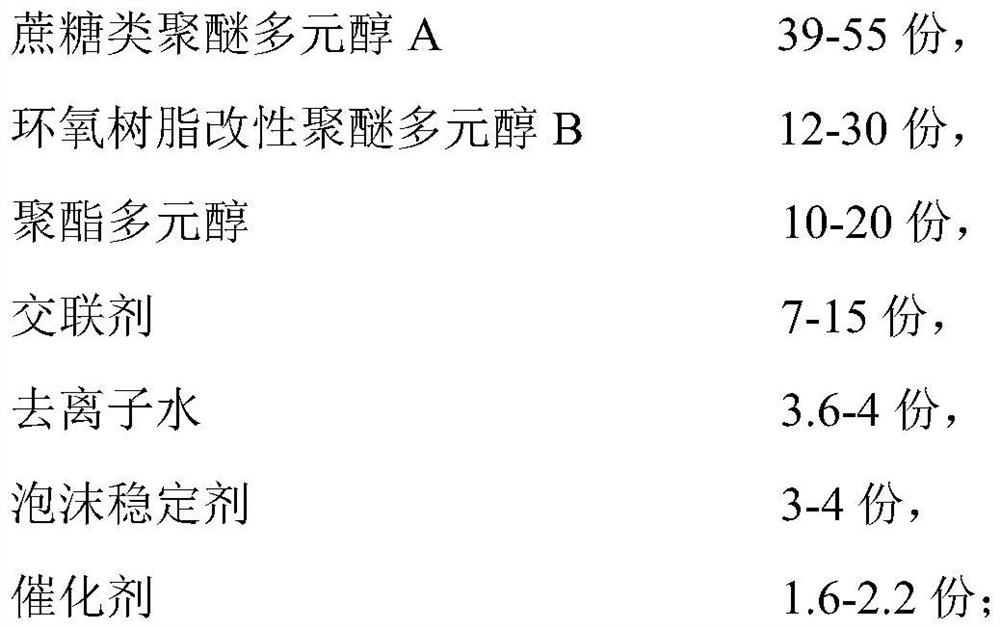

Method used

Image

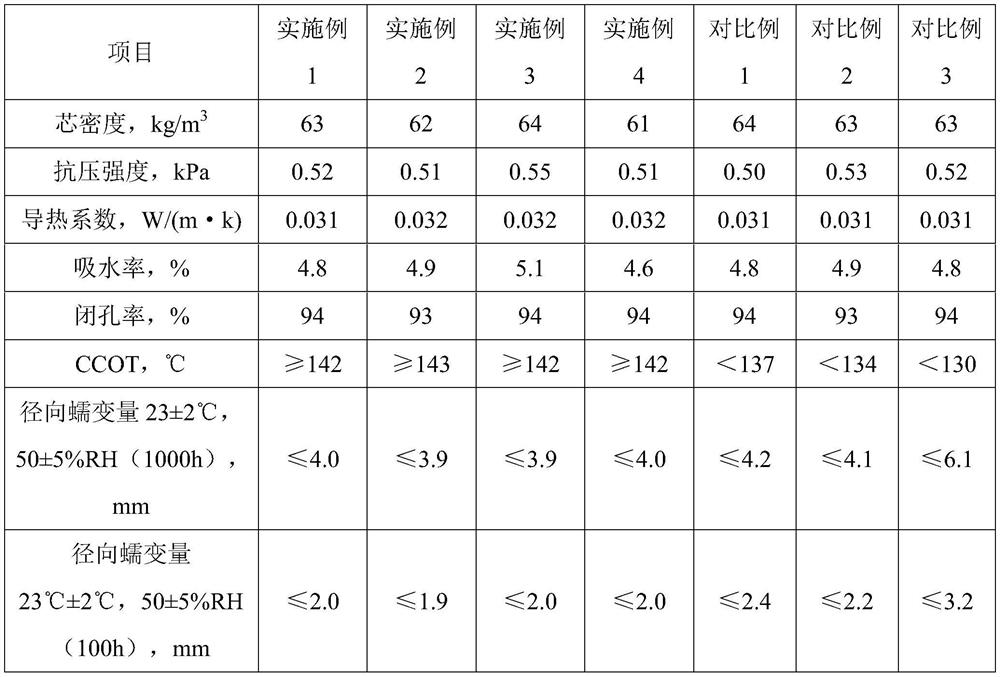

Examples

preparation example Construction

[0030] The preparation method of the modified isocyanate adopted in the embodiment is:

[0031] Stir and vacuum dehydrate the hydroxyl-terminated fluorine-containing polyester polysiloxane and hydroxyl-terminated polysiloxane at 100°C, then cool down to 50°C and add polymethylene polyphenyl polyisocyanate and diphenylmethane diisocyanate , react at a temperature of 85°C to prepare a modified isocyanate, which is packaged for future use. Among them, the addition amount of hydroxyl-terminated fluorine-containing polyester polysiloxane and hydroxyl-terminated polysiloxane is 15%, and the mass ratio of polymethylene polyphenyl polyisocyanate to diphenylmethane diisocyanate is 1:0.8, and the modification is controlled. The isocyanate NCO content is 25%.

[0032] The manufacturer of polyester polyol PS-3152 adopted in the embodiment is Nanjing Jinling Stepan Chemical Co., Ltd.; the manufacturer of foam stabilizer B84817 is Evonik Degussa Company of Germany; the manufacturer of poly...

Embodiment 1

[0034] (1) Component A: Weigh sucrose polyether polyol A (functionality: 5.7, hydroxyl value: 410±5mgKOH / g, viscosity at 25°C: 13500±100mpa·s, use sucrose and glycerin as composite initiators ) 44.4 parts, epoxy resin modified polyether polyol B30 parts, polyester polyol PS-3152 10 parts, 1,4 butanediol 4 parts, dodecyl glycol 3 parts, deionized water 3.6 parts, foam 3 parts of stabilizer B84817, 0.2 parts of trimethylhydroxyethylethylenediamine, 1 part of N,N-bis(dimethylaminopropyl)isopropanolamine, 2,4,6-tris(dimethylaminomethyl) ) 0.8 part of phenol, stirred evenly at normal temperature to obtain component A;

[0035] (2) Component B: Weigh 70 parts of polymethylene polyphenyl polyisocyanate and 30 parts of modified isocyanate, and stir evenly at room temperature to obtain Component B;

[0036] (3) Mixing and curing: When in use, mix and foam components A and B at a mass ratio of 1:1.5 to obtain high temperature and creep resistant pipeline insulation materials.

Embodiment 2

[0038] (1) Component A: Weigh sucrose polyether polyol A (functionality 5.6, hydroxyl value 400±5mg KOH / g, viscosity at 25°C 13000±100mpa s, starting with sucrose and glycerin) agent) 55 parts, epoxy resin modified polyether polyol B12 parts, polyester polyol PE-B503L 15 parts, 1,3 butanediol 4 parts, dodecyl glycol 5 parts, deionized water 3.8 parts, 3 parts of foam stabilizer B84817, 0.4 parts of trimethylhydroxyethylethylenediamine, 0.9 parts of N,N-bis(dimethylaminopropyl)isopropanolamine, 2,4,6-tris(dimethylaminomethyl) base) 0.9 parts of phenol, stirred evenly at room temperature to obtain component A;

[0039] (2) Component B: Weigh 80 parts of polymethylene polyphenyl polyisocyanate and 20 parts of modified isocyanate, and stir evenly at room temperature to obtain Component B;

[0040] (3) Mixing and curing: when in use, mix and foam component A and component B at a mass ratio of 1:1.4 to obtain high temperature and creep resistant pipeline insulation materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com