Array laser based on waveguide grating coupler and preparation method thereof

A grating coupler and waveguide grating technology, applied in the laser field, can solve the problems of high device cost and large volume, and achieve the effect of cost advantage, excellent production yield and process applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

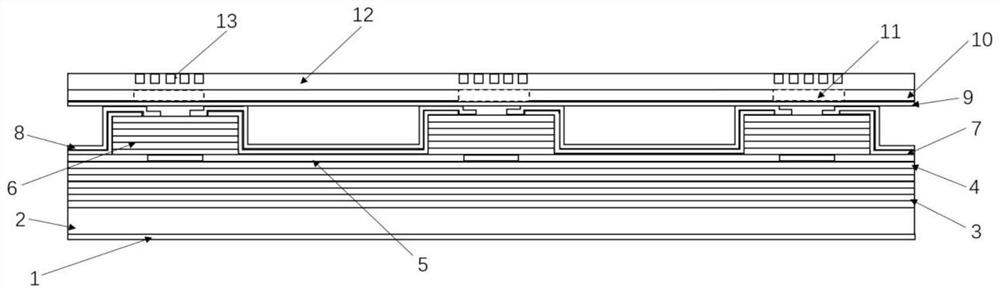

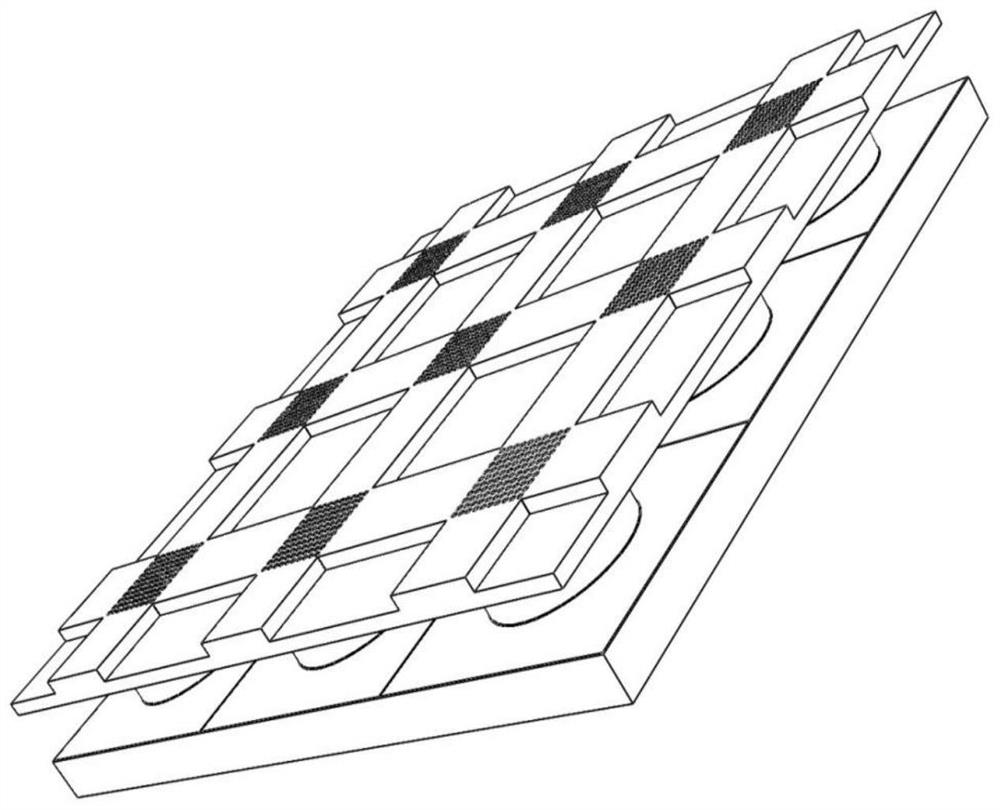

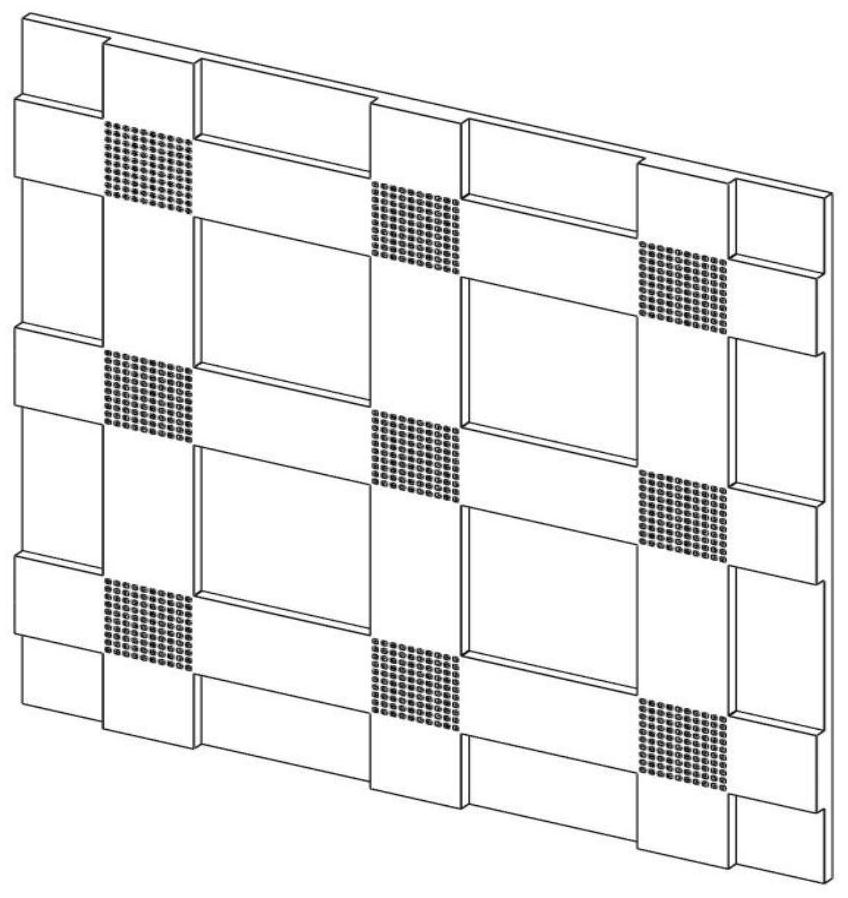

[0066] The embodiment of the present invention proposes a preparation method of a two-dimensional waveguide grating coupler, such as Figure 5 to Figure 12 As shown, the steps include:

[0067] 110, using RIE (Reactive Ion Etching) to etch a vertical coupling waveguide hole in the waveguide base layer;

[0068] 120. Using ICPCVD to grow Si on the surface of quartz glass after etching the vertical coupling waveguide hole 3 N 4 , to fill the previously etched holes to form a vertical coupling waveguide;

[0069] 130, using a polishing process to polish off the excess Si grown on the surface of the quartz glass in the previous step 3 N 4 , so that the quartz glass is exposed, and at the same time it can flatten the glass surface.

[0070] 140, again using the ICPCVD process to grow a layer of Si with precise thickness and flatness on the flat quartz glass 3 N 4 As a transverse coupling waveguide layer;

[0071] 150, using RIE to etch a transverse coupling waveguide;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com