Difunctional pressure sensor alumina ceramic material and preparation method thereof

A technology of pressure sensors and alumina ceramics, applied in ceramic products, other household appliances, applications, etc., can solve the problems of poor impact resistance, high dielectric loss, low dielectric constant, etc., to improve insulation performance, high dielectric Electricity constant, the effect of increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

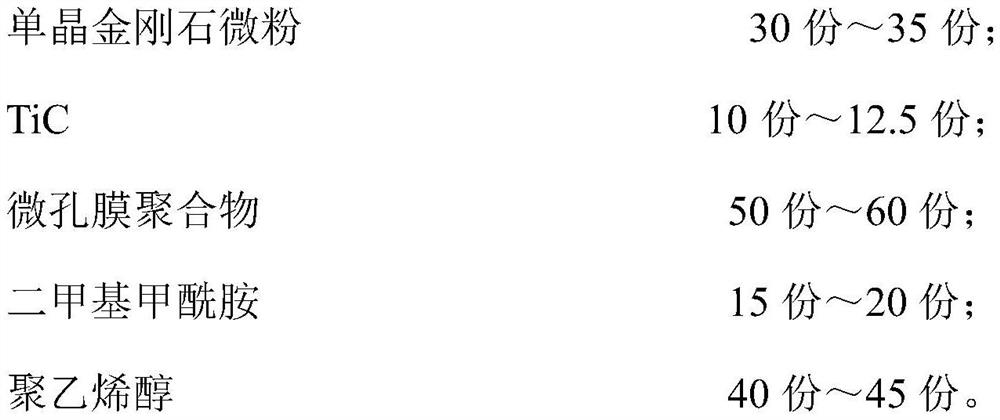

[0034] A dual-function pressure sensor alumina ceramic material provided in this embodiment includes the following components by weight components:

[0035]

[0036]

[0037] Among them, the CaCu 2.5 Ni 0.5 Ti 4 o 12 The preparation method of nano particle material, comprises the following steps:

[0038] S1: Add 5 parts of tetraisopropyl bis(dioctylphosphite acyloxy) titanate to 20 parts of acrylic acid, and stir evenly at 150 rpm;

[0039] S2: To the mixed solution obtained in step S1, add Ca(NO 3 ) 2 4H 2 O, Cu(NO 3 ) 2 ·3H 2 O and Ni(NO 3 ) 2 ·6H 2 O, ultrasonically oscillate at 100°C for 1 h, and continuously add 12 parts of 5% ammonium persulfate solution dropwise during the oscillating process;

[0040] S3: Stir the mixture obtained in step S1 and the mixture obtained in step S2 at 65°C and 300rpm to 350rpm for 20min to obtain CaCu 2.5 Ni 0.5 Ti 4 o 12 Nano precursor solution;

[0041] S4: the CaCu obtained in the step S3 2.5 Ni 0.5 Ti 4 o 12...

Embodiment 2

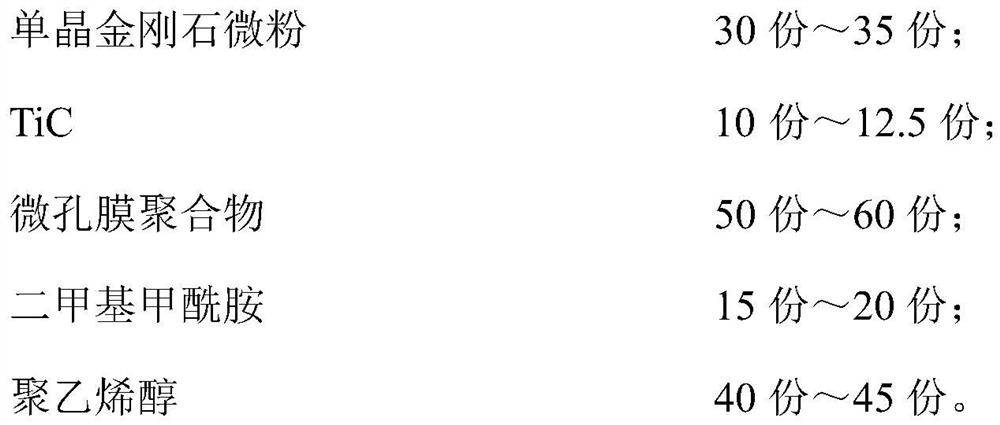

[0049] A dual-function pressure sensor alumina ceramic material provided in this embodiment includes the following components by weight components:

[0050]

[0051]

[0052] Among them, CaCu 2.75 (Zr 0.5 co 0.5 ) 0.25 Ti 4 o 12 The preparation method of nano particle material comprises the following steps:

[0053] S1: Add 7.5 parts of isopropyl titanate to 22.5 parts of acrylic acid, and stir evenly at 175 rpm;

[0054] S2: To the mixed solution obtained in step S1, add CaSO with a molar ratio of Ca, Cu, Zr and Co of 1:2.75:0.125:0.125 4 2H 2 O, CuSO 4 ·5H 2 O, Zr(SO 4 ) 2 4H 2 O and Co(SO 4 ) 2 ·7H 2 O, ultrasonically oscillate at 118°C for 1.25h, and continuously add 15 parts of ammonium persulfate solution with a concentration of 6.5% dropwise during the oscillating process;

[0055] S3: Stir the mixture obtained in step S1 and the mixture obtained in step S2 at 70°C and 325rpm for 25min to obtain CaCu 2.75 (Zr 0.5 co 0.5 ) 0.25 Ti 4 o 12 Nano ...

Embodiment 3

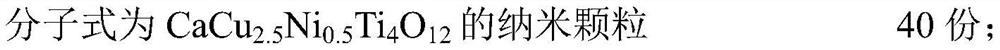

[0064] A dual-function pressure sensor alumina ceramic material provided in this embodiment includes the following components by weight components:

[0065]

[0066]

[0067] Among them, CaCu 2 (Co 0.7 Sr 0.3 ) 1 Ti 4 o 12 The preparation method of nano particle material comprises the following steps:

[0068] S1: Add 10 parts of diisopropyl bis(acetylacetonate) titanate to 25 parts of acrylic acid, and stir evenly at 200 rpm;

[0069] S2: Add CaCl with a molar ratio of Ca, Cu, Co and Sr of 1:2:0.7:0.3 to the mixed solution obtained in step S1 2 ·6H 2 O, CuCl 2 2H 2 O, CoCl 2 ·6H 2 O and SrCl 2 ·6H 2 O, ultrasonically oscillate at 135°C for 1.5h, and continuously add 18 parts of ammonium persulfate solution with a concentration of 8% dropwise during the oscillating process;

[0070] S3: Stir the mixture obtained in step S1 and the mixture obtained in step S2 at 75°C and 300rpm to 350rpm for 30min to obtain CaCu 2 (Co 0.7 Sr 0.3 ) Ti 4 o 12 Nano precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com