Sand core composite coating for casting and application thereof

A composite coating and foundry sand technology, applied in foundry molding equipment, coatings, molds, etc., can solve problems such as poor leveling and wettability of coatings, insufficient bonding between sand cores and coatings, and affecting casting, etc. Achieve good plane integrity, good transfer resonance effect, and improve the effect of surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

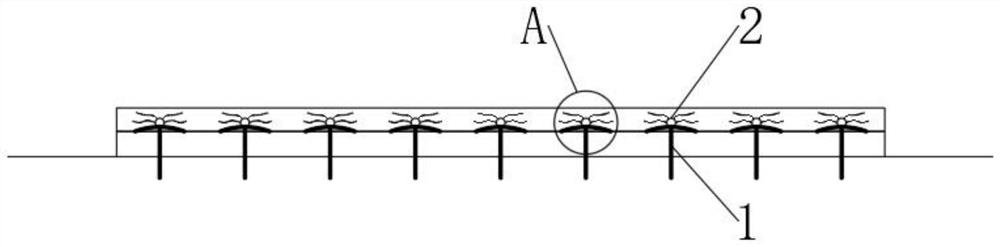

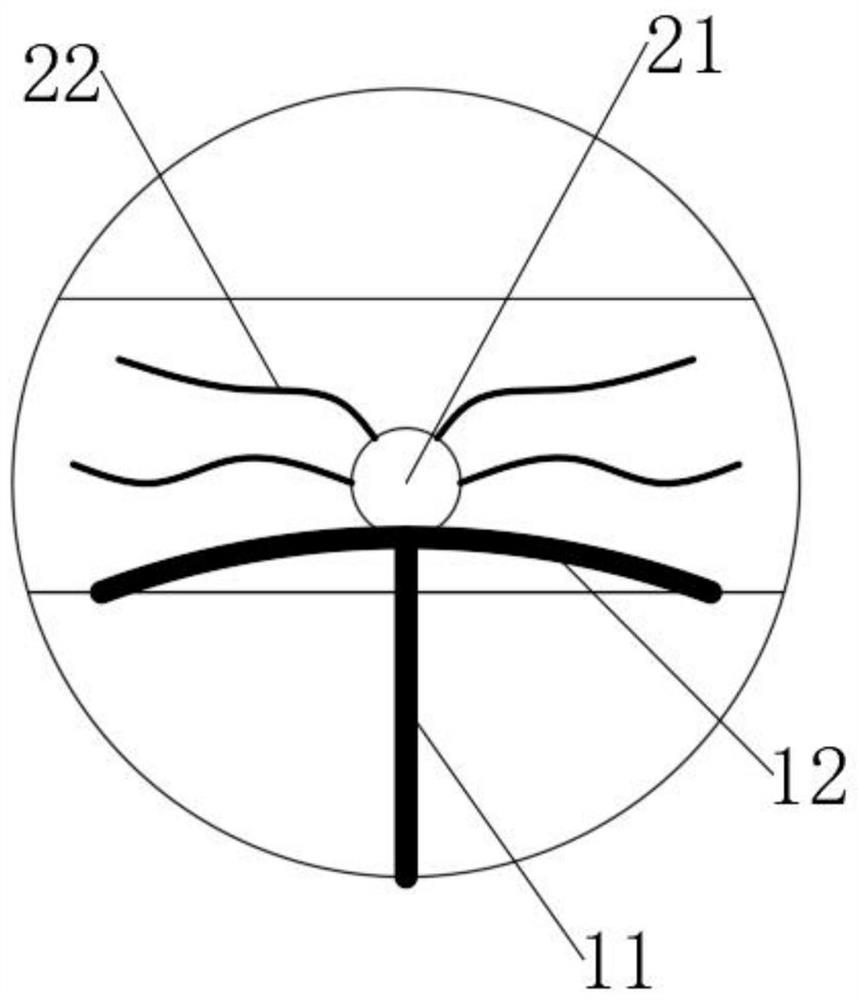

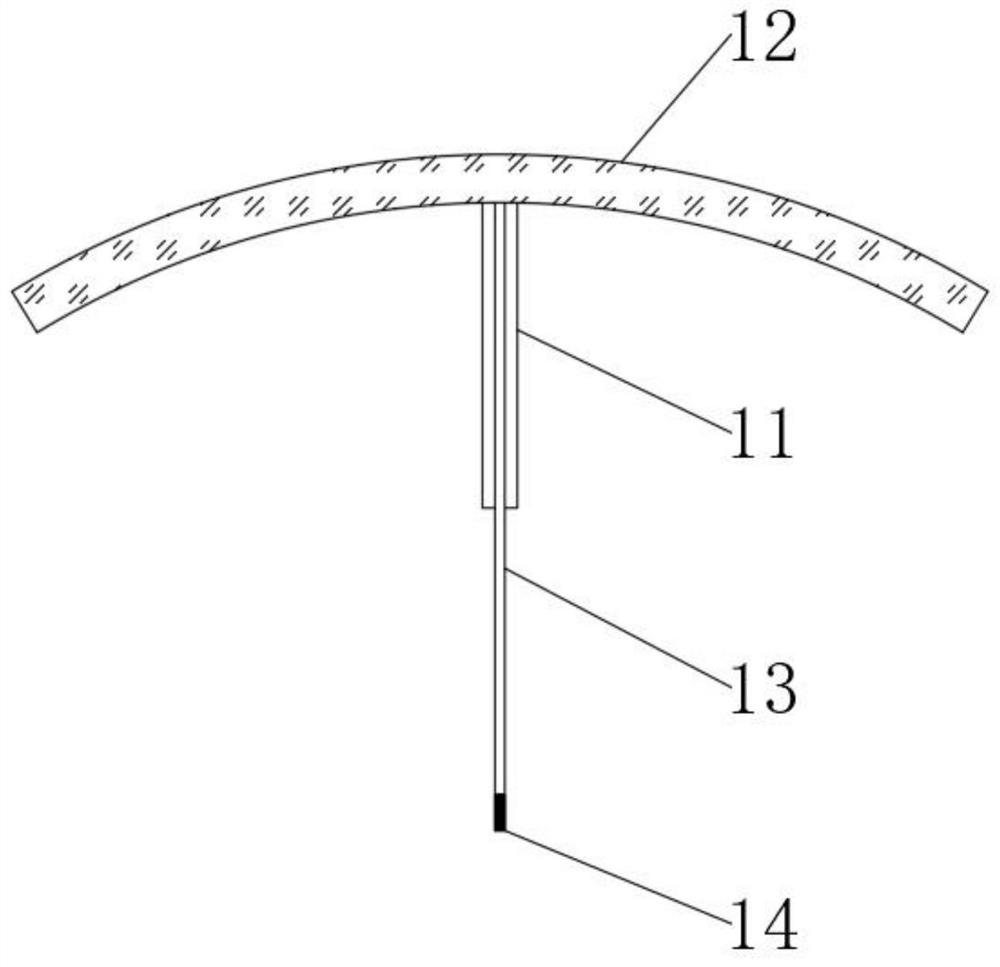

[0041] see Figure 1-2 , a sand core composite coating for foundry, including permanent coating and stripping coating, permanent coating includes the following raw materials in parts by weight: 60-80 parts of silicon micropowder, 15-25 parts of diatomite, 10-25 parts of graphite powder 20 parts, corundum powder 10-16 parts, talc powder 18-22 parts, sodium silicate 15-24 parts, silane coupling agent 5-8 parts, polyisobutylene 10-15 parts, ethanol 20-30 parts and water 20- 30 parts, and the permanent paint is mixed with an extension cap 1 with a mass ratio of 5%-10%;

[0042] The peeling paint includes the following raw materials in parts by weight: 80-100 parts of silica sand, 20-40 parts of mica-like aluminosilicate, 10-15 parts of bentonite, 8-12 parts of flaky graphite powder, 10-16 parts of talcum powder 0.1-0.5 parts of defoamer, 1.2-1.5 parts of suspending agent, 3-5 parts of epoxy resin, 2-4 parts of silica sol, 40-60 parts of water and 3-5 parts of degaussing powder, a...

Embodiment 2

[0057] A composite coating for sand cores for casting, comprising a permanent coating and a stripping coating. The permanent coating includes the following raw materials in parts by weight: 60-80 parts of silicon micropowder, 15-25 parts of diatomite, and 10-20 parts of graphite powder 10-16 parts of corundum powder, 18-22 parts of talc powder, 15-24 parts of sodium silicate, 5-8 parts of silane coupling agent, 10-15 parts of polyisobutylene, 20-30 parts of ethanol and 20-30 parts of water part, and the permanent paint is mixed with an extension cap 1 with a mass ratio of 5%-10%;

[0058] The peeling paint includes the following raw materials in parts by weight: 80-100 parts of silica sand, 20-40 parts of mica-like aluminosilicate, 10-15 parts of bentonite, 8-12 parts of flaky graphite powder, 10-16 parts of talcum powder 0.1-0.5 parts of defoamer, 1.2-1.5 parts of suspending agent, 3-5 parts of epoxy resin, 2-4 parts of silica sol, 40-60 parts of water and 3-5 parts of degaus...

Embodiment 3

[0061] A composite coating for sand cores for casting, comprising a permanent coating and a stripping coating. The permanent coating includes the following raw materials in parts by weight: 60-80 parts of silicon micropowder, 15-25 parts of diatomite, and 10-20 parts of graphite powder 10-16 parts of corundum powder, 18-22 parts of talc powder, 15-24 parts of sodium silicate, 5-8 parts of silane coupling agent, 10-15 parts of polyisobutylene, 20-30 parts of ethanol and 20-30 parts of water part, and the permanent paint is mixed with an extension cap 1 with a mass ratio of 5%-10%;

[0062] The peeling paint includes the following raw materials in parts by weight: 80-100 parts of silica sand, 20-40 parts of mica-like aluminosilicate, 10-15 parts of bentonite, 8-12 parts of flaky graphite powder, 10-16 parts of talcum powder 0.1-0.5 parts of defoamer, 1.2-1.5 parts of suspending agent, 3-5 parts of epoxy resin, 2-4 parts of silica sol, 40-60 parts of water and 3-5 parts of degaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com