Case of electronic device and manufacturing method therefor

A technology for electronic devices and manufacturing methods, applied in chemical instruments and methods, casings, telephone communications, etc., can solve the problems of low surface flatness of the casing, low production efficiency, difficult to roll evenly, etc., and achieve high appearance quality. , The effect of improving surface flatness and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

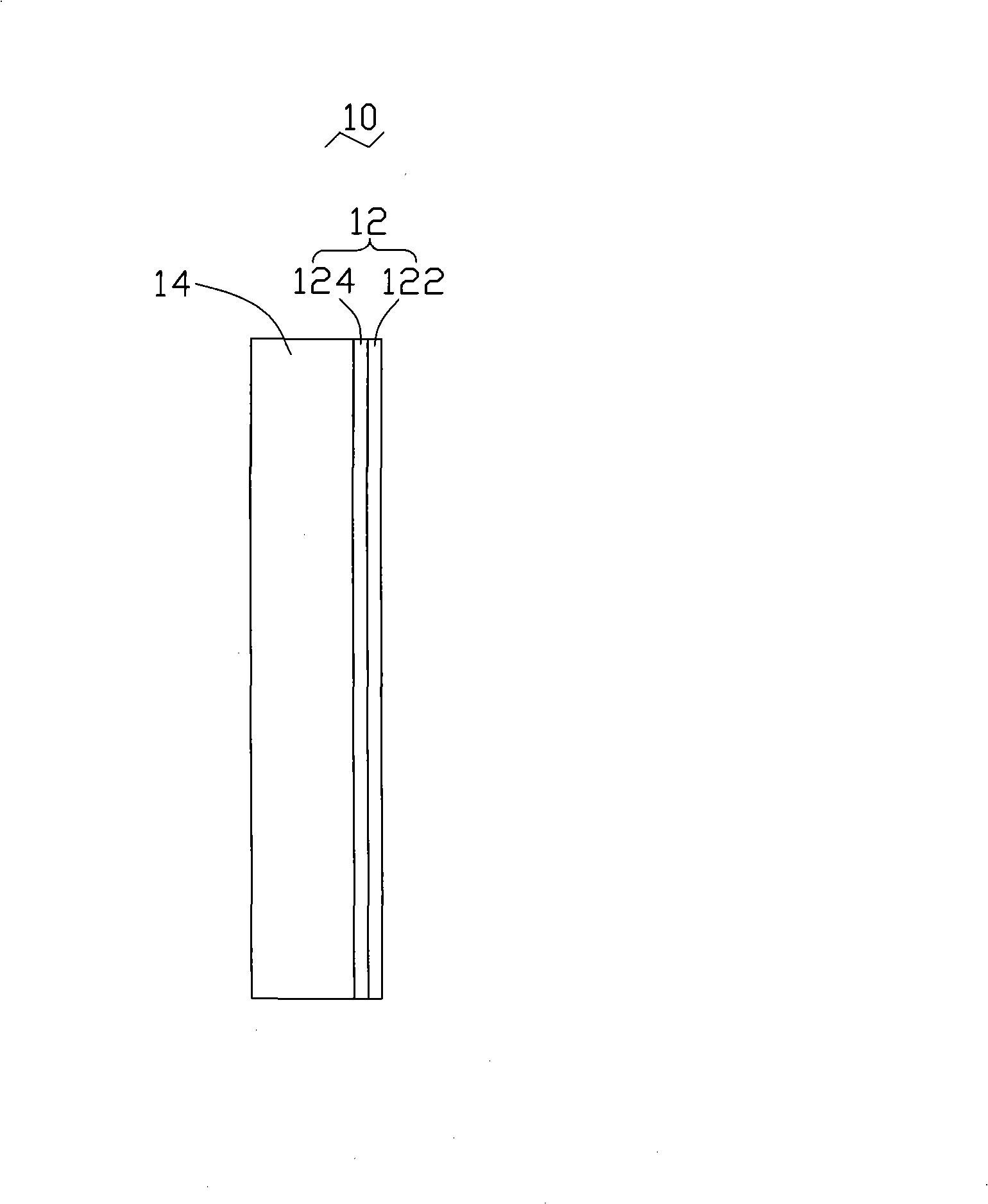

[0019] see figure 1 , shows an electronic device housing 10 according to a preferred embodiment of the present invention, the electronic device housing 10 includes a decorative layer 12 and a plastic layer 14, the electronic device housing 10 is integrated by the decorative layer 12 and the plastic layer 14 Formed.

[0020] The decoration layer 12 is disposed on the outer surface of the housing 10 of the electronic device, and characters or graphics are formed thereon. The decorative layer 12 includes a thin film layer 122 and an electronic ink layer 124, the thin film layer 122 is a transparent film, such as the transparent plastic film used in the molding technology of IN MOLDING LAMINATION (IML), it can also be made of glass , fibers, alloys, polymer materials, etc.; the electronic ink layer 124 is a coating containing ink particles, which form characters or graphics through the arrangement of ink particles. The ink particles are charged, which can be controlled by an ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com