Method for using coke oven to dispose of waste-derived fuel and product cascade resource utilization

A waste-derived fuel and recycling technology, applied in biofuels, coke ovens, energy input, etc., can solve the problems of inability to be applied on a large scale, small processing capacity, and low degree of automation, and shorten the pretreatment process and reduce processing costs , Improve the effect of incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

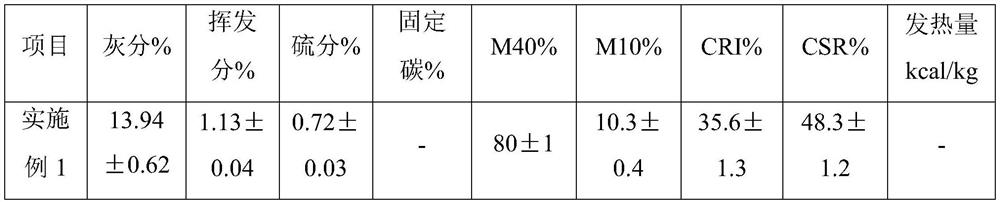

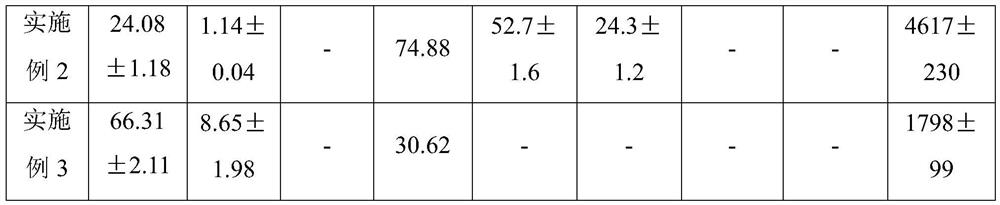

Embodiment 1

[0022] A total of 40Kg of RDF and fat coal mixed with domestic waste, charcoal and coal powder are fully crushed and mixed in a mass ratio of 3:97, and put into a 40Kg experimental top-loading coke oven. to 1100±50°C, and then out of the oven after constant temperature. A total of 30.8Kg of dry distillation solids (including tar and other organic liquid substances) and a total of 12.48m of dry distillation gas 3 . The solid composition analysis is shown in Table 1, and the gas analysis is shown in Table 2. According to the Chinese metallurgical coke quality standard (GB / T1996—2003), the parameters of Class III metallurgical coke are specified in the range of ash content ≤ 15%, volatile content ≤ 1.8, sulfur content ≤ 1.00, M40 ≥ 72, M10 ≤ 10.5. The CRI and CSR of Class III metallurgical coke are not limited to a clear range, and the requirements of Class II metallurgical coke are that CRI≤35% and CSR≥50. The carbonized solids released from the furnace meet the Class III met...

Embodiment 2

[0024] A total of 40Kg of RDF and fat coal mixed with domestic waste, charcoal and coal powder are fully crushed and mixed in a mass ratio of 3:7, and put into a 40Kg experimental top-loading coke oven. to 1100±50°C, and then out of the oven after constant temperature. A total of 31.81Kg of dry distillation solids (including tar and other organic liquid substances), a total of 8.18m of dry distillation gas 3 . The solid composition analysis is shown in Table 1, and the gas analysis is shown in Table 2. The calorific value of the dry distillation solid is about 4617Kcal / Kg, which can be used as a high-quality civil coke solid fuel. The calorific value of dry distillation gas is 14.93MJ / m 3 , about 78.6% of conventional coke oven gas, and the gas production rate is 0.30m 3 / Kg, the same gas production rate as conventional coke oven gas, which can be used in waste heat boilers and combustion furnaces.

Embodiment 3

[0026] After crushing 40Kg of 100% RDF, put it into a 40Kg experimental top-loading coke oven. The temperature of the furnace wall is 800°C when the furnace is loaded, and the temperature rises to 1100±50°C after 16 hours. A total of 29.64Kg of dry distillation solids (including tar and other organic liquid substances) and a total of 14m of dry distillation gases 3 . The solid composition analysis is shown in Table 1, and the gas analysis is shown in Table 2. The calorific value of the dry distillation solid is about 1798Kcal / Kg, which can be used as high-quality civil coke solid fuel or high-quality raw material for waste incineration plants. The calorific value of dry distillation gas is 13.99MJ / m 3 , about 73.6% of conventional coke oven gas, and the gas production rate is 0.35m 3 / Kg, the same gas production rate as conventional coke oven gas, which can be used in waste heat boilers and combustion furnaces.

[0027] Table 1 Analysis of solid components

[0028]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com