Manufacturing process of internal thread reinforced plastic pipe convenient to assemble

A manufacturing process and technology of plastic pipes, applied in the field of internal thread reinforced plastic pipe manufacturing technology, can solve the problems of troublesome molding and pressing, incapable of continuous production, etc., achieve the effects of fast forming speed, realization of continuity, and increase of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

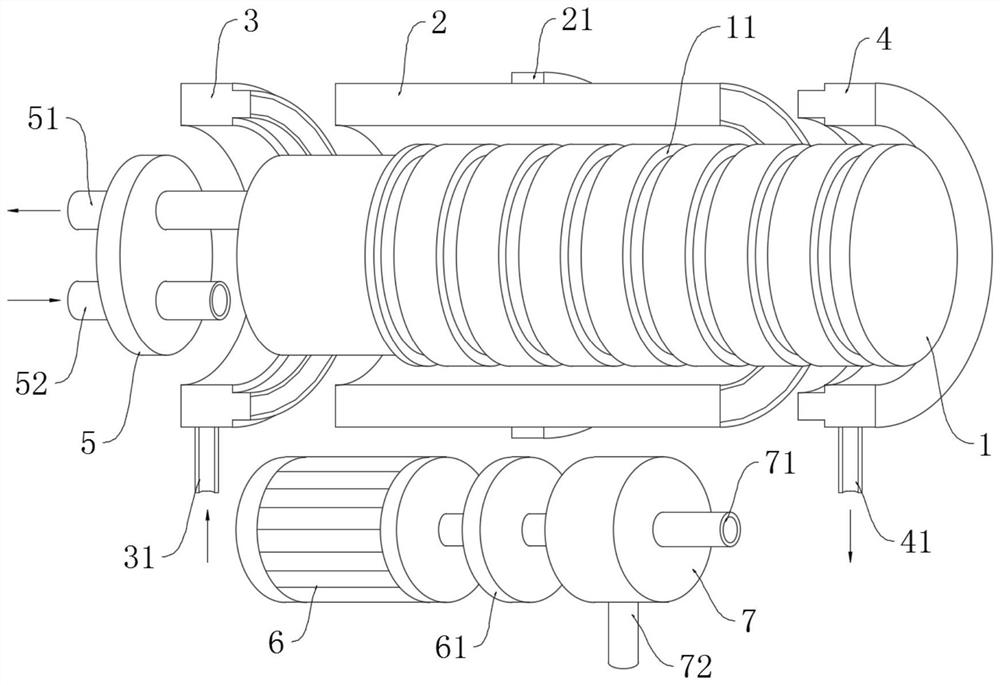

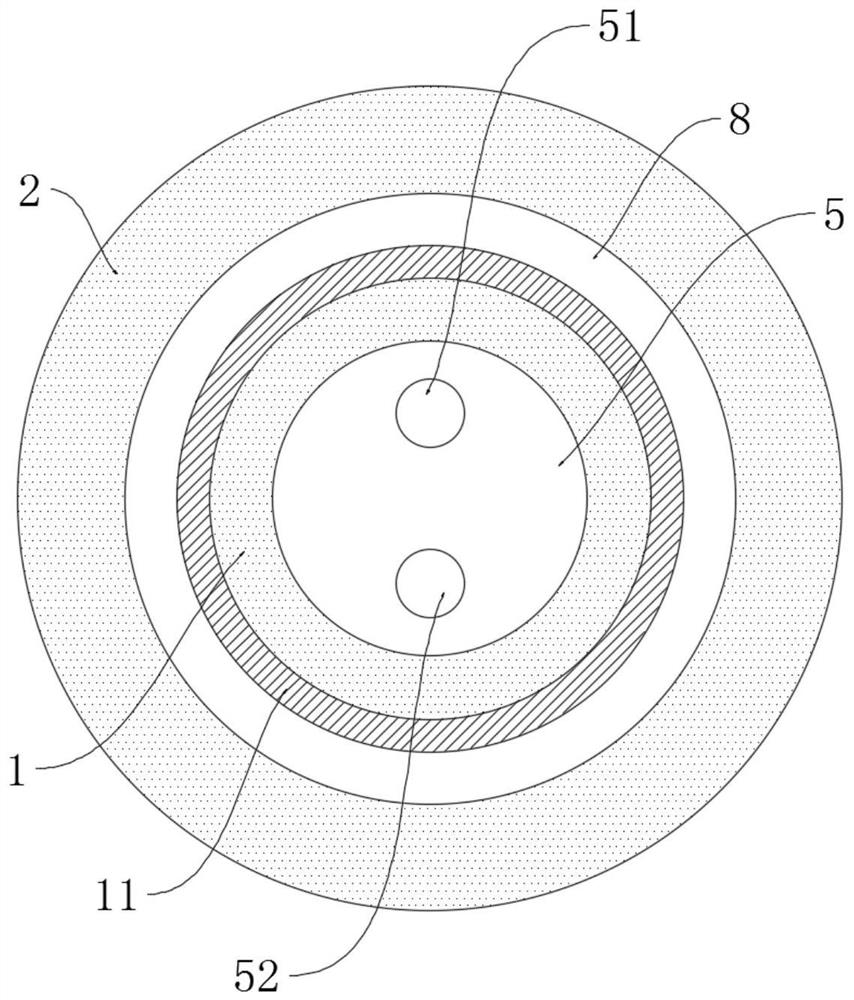

[0022] refer to Figure 1-3 , a manufacturing process for internally threaded reinforced plastic pipes that is easy to assemble, including the following main steps:

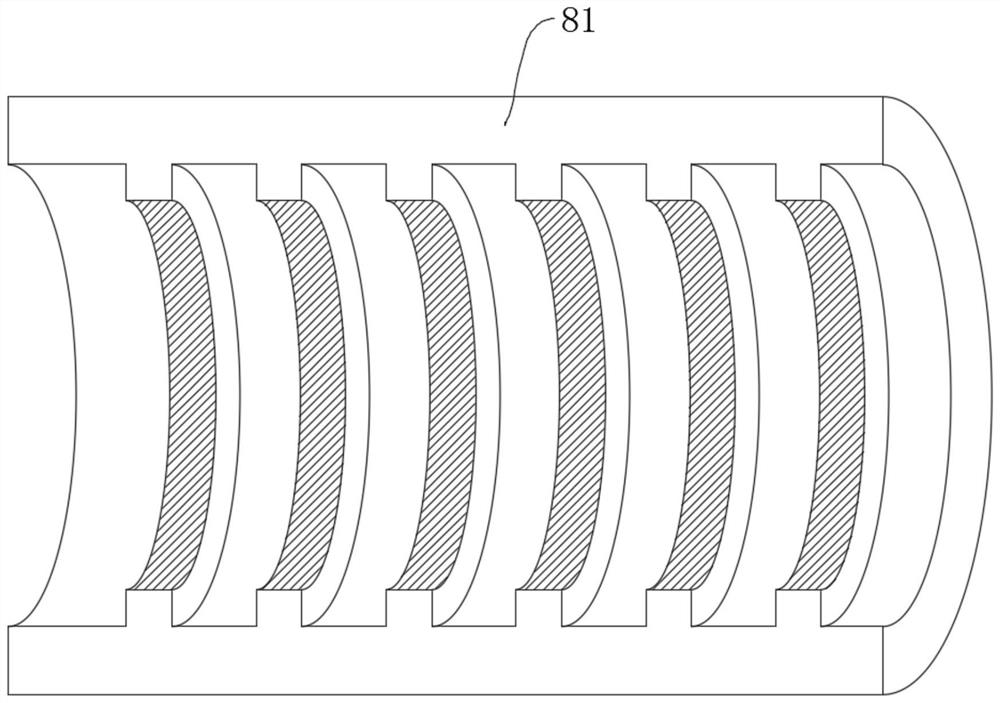

[0023] A, extrusion molding: the molten hot-melt plastic 81 is extruded into the die cavity 8 through an extruder, so that the hot-melt plastic 81 forms an internally threaded plastic pipe;

[0024] B. Temperature difference cooling: the motor 6 rotates so that the cooling water in the cooling pool is pumped into the pump body 7 through the water pipe 72 and sent into the short pipe 52 through the water delivery pipe 71 to enter the mold tube 1, and the cooling water in the mold tube 1 exchanges heat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com